A machine-added online detection method based on integrated application of 3D model

A three-dimensional model and detection method technology, applied in general control systems, electrical testing/monitoring, testing/monitoring control systems, etc., can solve problems such as increased workload, unfavorable development, and insufficient information connectivity, and improve process design and inspection. horizontal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

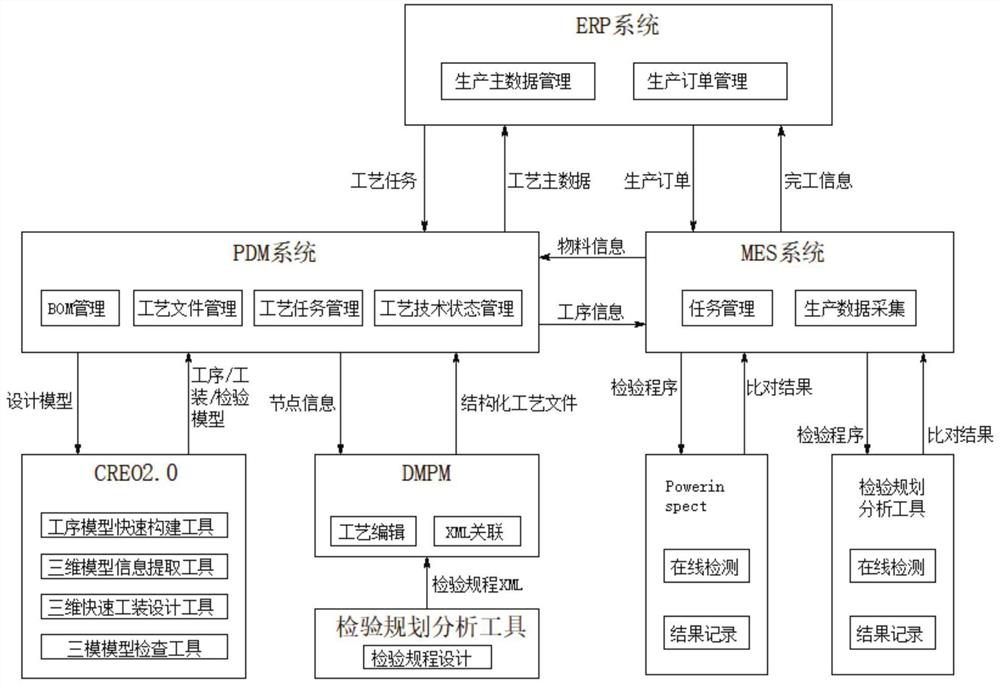

[0047] The CREO2.0 system is integrated with process model rapid construction tools, 3D model information extraction tools, 3D rapid tooling design tools and 3D model inspection tools, process model rapid construction tools, 3D model information extraction tools, 3D rapid tooling design tools and 3D models The inspection tools all adopt the interface method embedded in the package, and the structured information transmitted includes part number, part name, process number, process name, inspection requirements, inspection methods, and dimension names;

[0048] The DMPM system integrates a process editing module and an XML association module, and the DMPM system is attached with an inspection planning analysis tool;

[0049] The main plan is: carry out secondary transformation and development of PDM, expand the contents of the submitted attachments, add XML files of inspection planning, numerical control program files and inspection program files, and uniformly connect them to th...

Embodiment 3

[0060] The integrated technical scheme of MES system and online detection software is as follows:

[0061] The MES system and Powerinspect are integrated by uploading Excel files. The MES system supports the analysis and data extraction of the Powerinspect inspection result excel files, and records the results according to the product number, process number, and size number;

[0062] The MES system and the inspection planning analysis tool are integrated by uploading Excel files. The MES system supports the analysis and data extraction of the Excel file of the inspection planning analysis tool inspection results, and records the results according to the product number, process number, and size number;

[0063] The results transmitted from Powerinspect to MES include the interpretation results of measured data; the results transmitted to MES by inspection planning and analysis tools only contain the results of measured data, which are interpreted by the MES system;

[0064] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com