Petrochemical enterprise equipment in-plant inspection system and method

An inspection system and equipment inspection technology, applied in the direction of office automation, collaborative operation devices, instruments, etc., can solve problems that cannot meet equipment inspection, dynamic tracking, timely rectification feedback, equipment information acquisition is limited by time and place, and equipment inspection results cannot be Timely rectify and other problems to achieve the effect of promoting orderly management, optimizing process and complexity, and improving inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

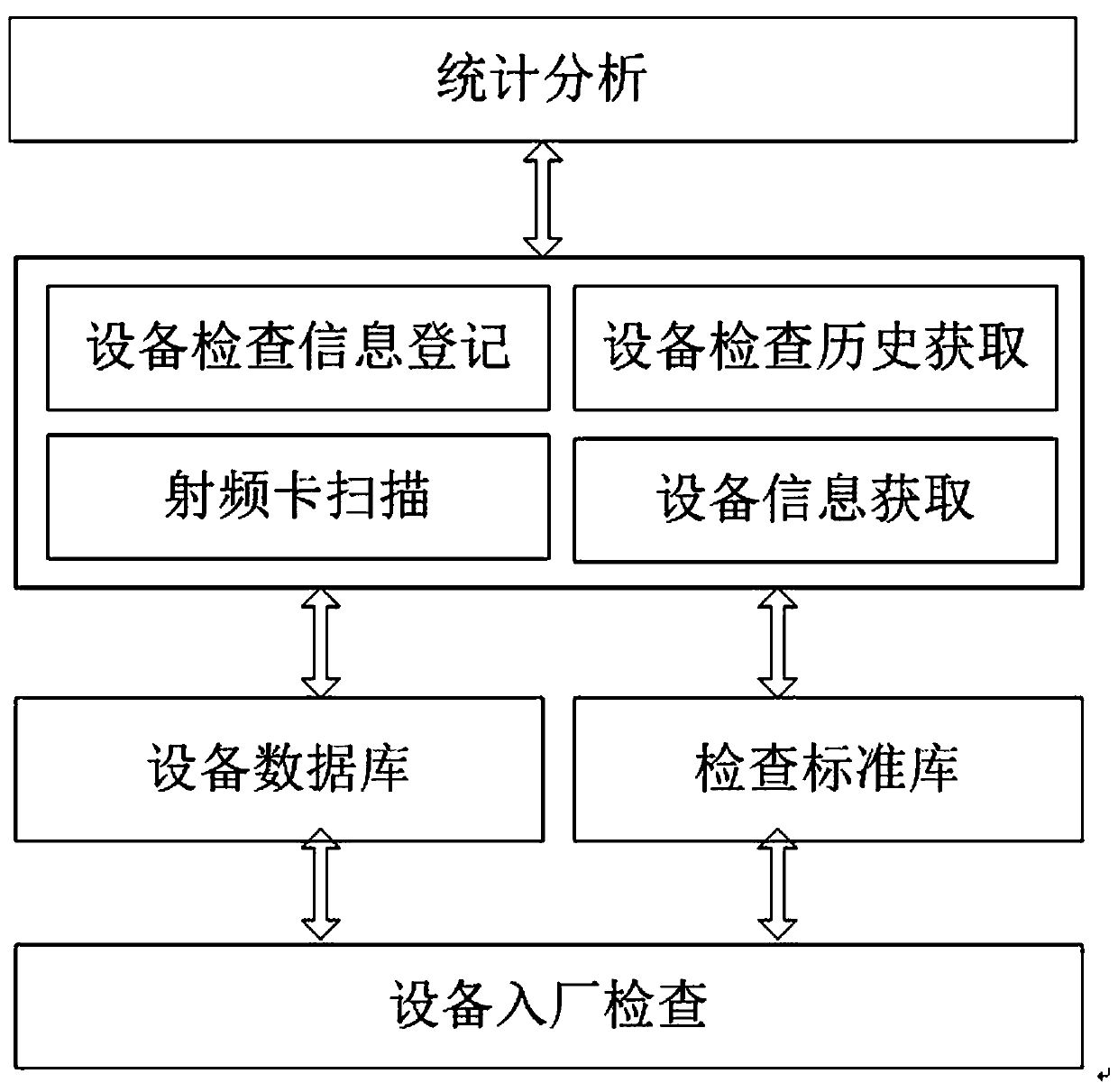

[0024] When in use, the system administrator collects and imports basic information such as organization, users, and equipment inspection standards into the system to complete system initialization. The system is based on each person's position, level, and position, and the system administrator controls the operation authority of each user through roles. Each user has its own independent account and password. After logging in to the system, users can perform corresponding operations such as adding, deleting, and browsing according to their permissions.

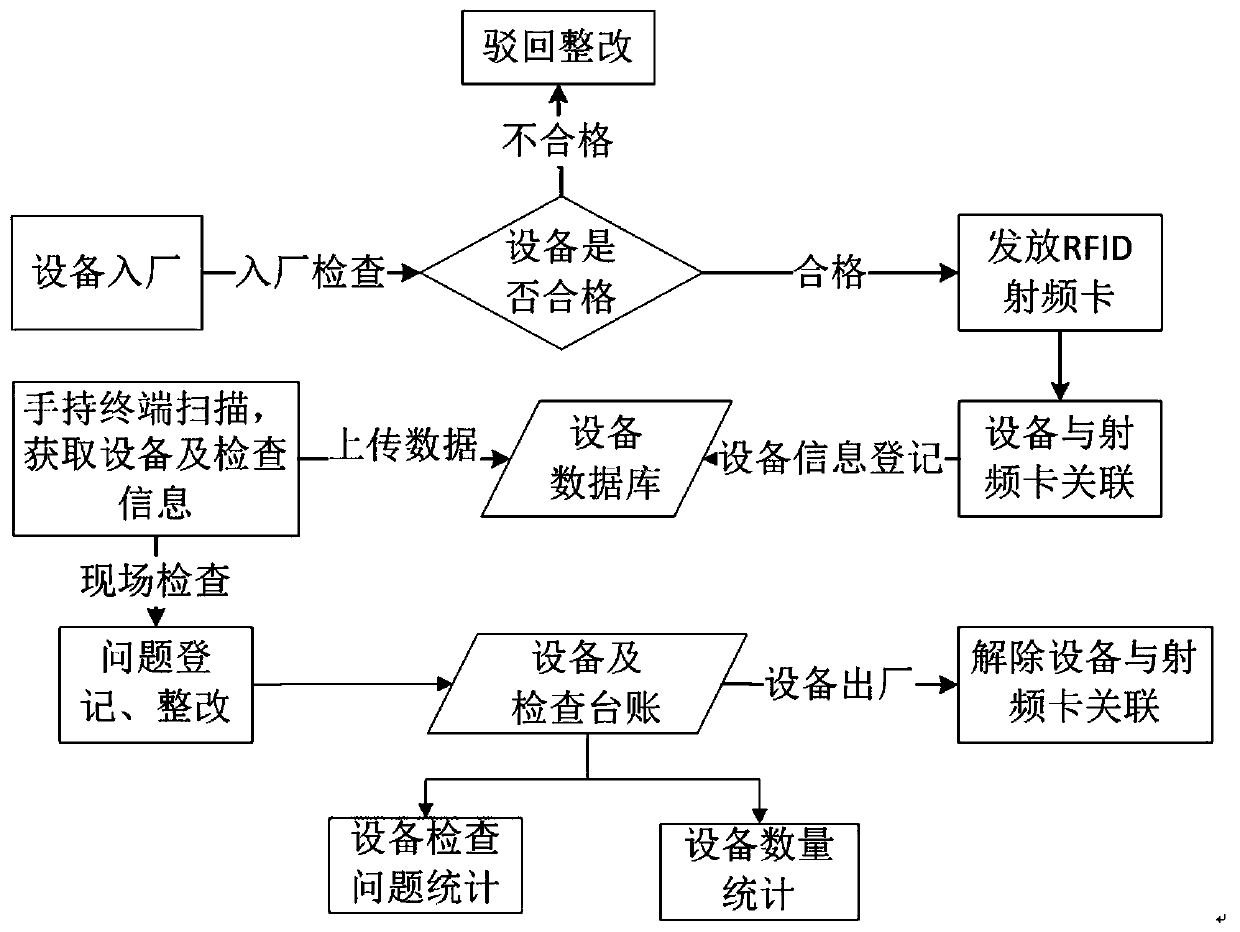

[0025] When construction operations such as inspection and maintenance projects start, safety supervisors use explosion-proof handheld terminals to inspect general equipment and special equipment, and judge whether the equipment is in good condition and meets the requirements for entering the factory according to inspection standards. After passing the factory inspection, an RFID radio frequency card is issued to the equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com