Portable cotton grade inspection equipment and method

A kind of inspection equipment and portable technology, which is applied in the field of portable cotton grade inspection equipment, can solve the problems that the device is not suitable for moving, cannot be easily moved at any time, and cannot meet the needs, so as to improve the overall inspection level and meet the needs of sampling inspection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This embodiment mainly introduces the basic composition of a portable cotton grade inspection equipment.

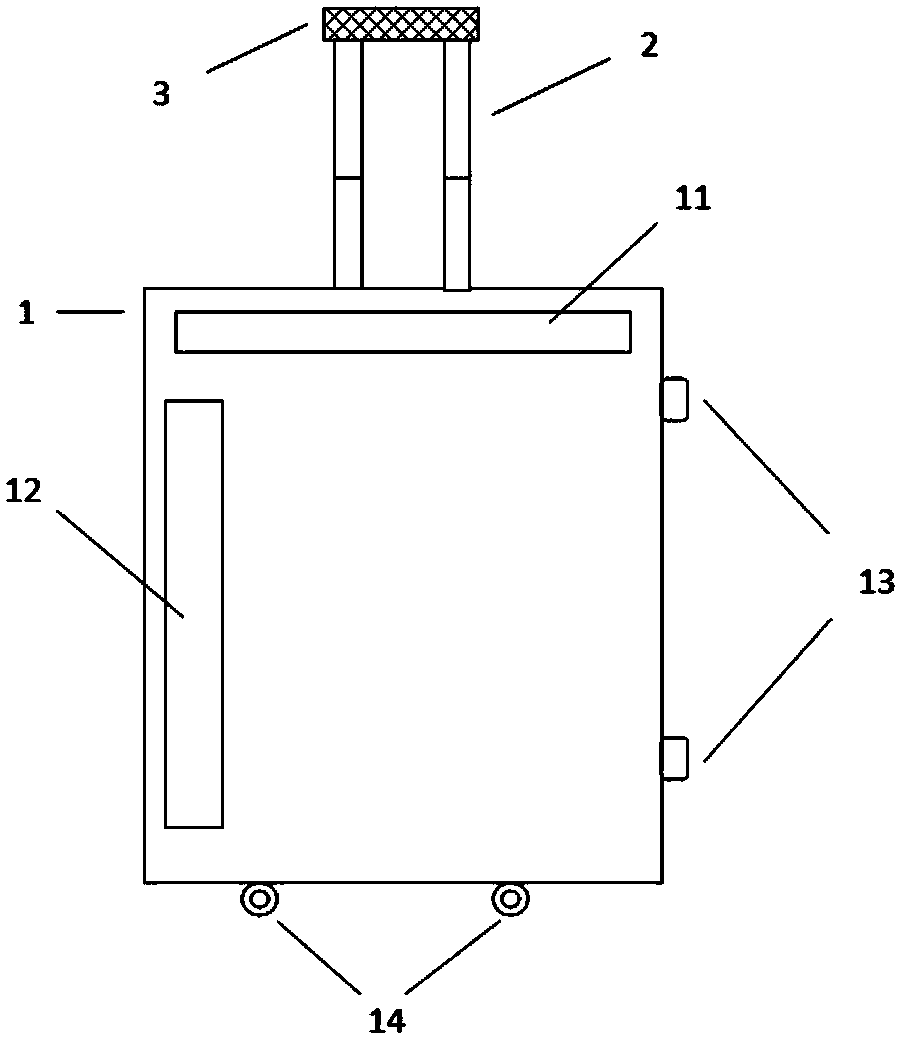

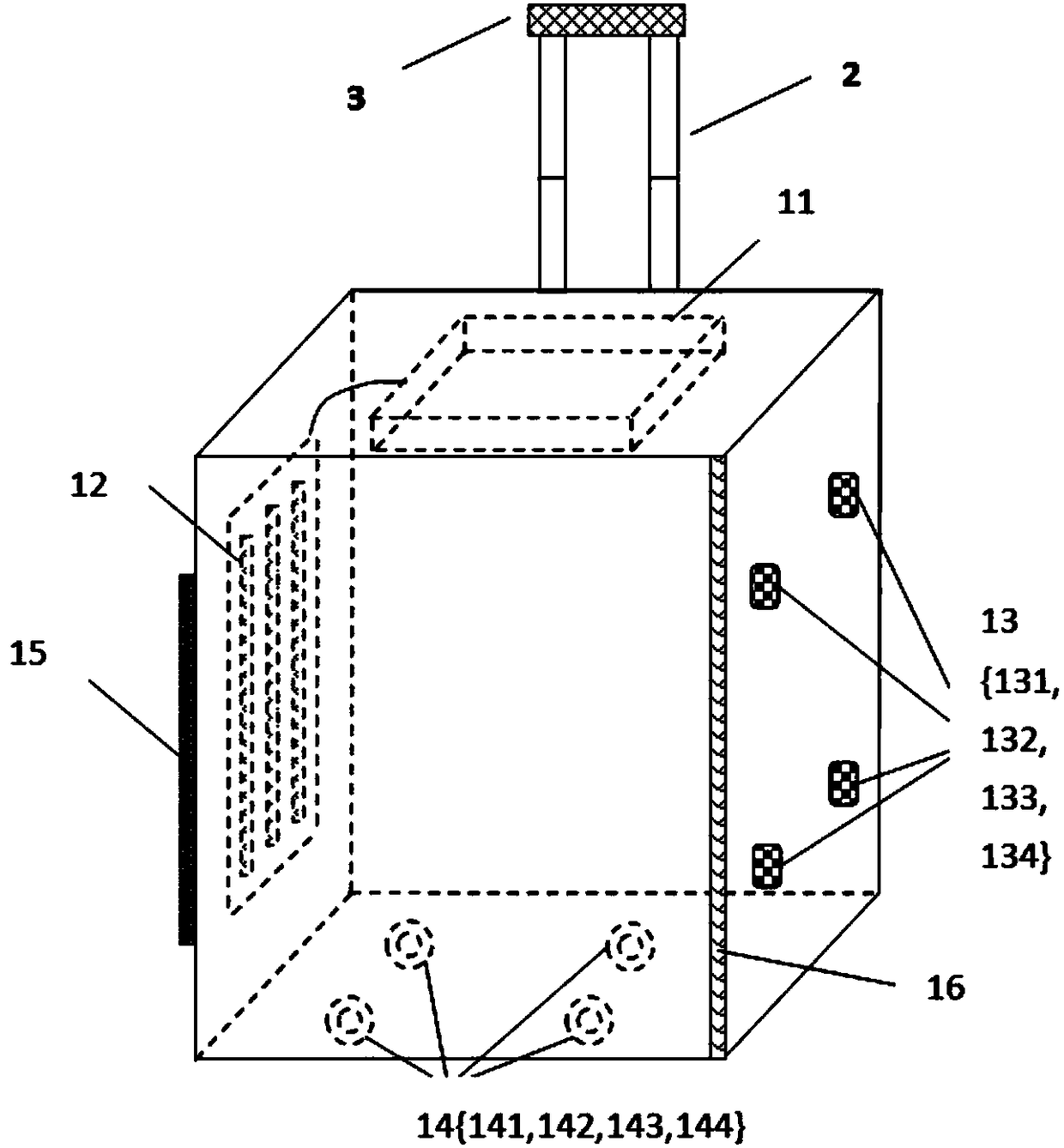

[0054] as attached figure 1 As shown in , it is a schematic diagram of the basic composition of the portable cotton grade inspection equipment.

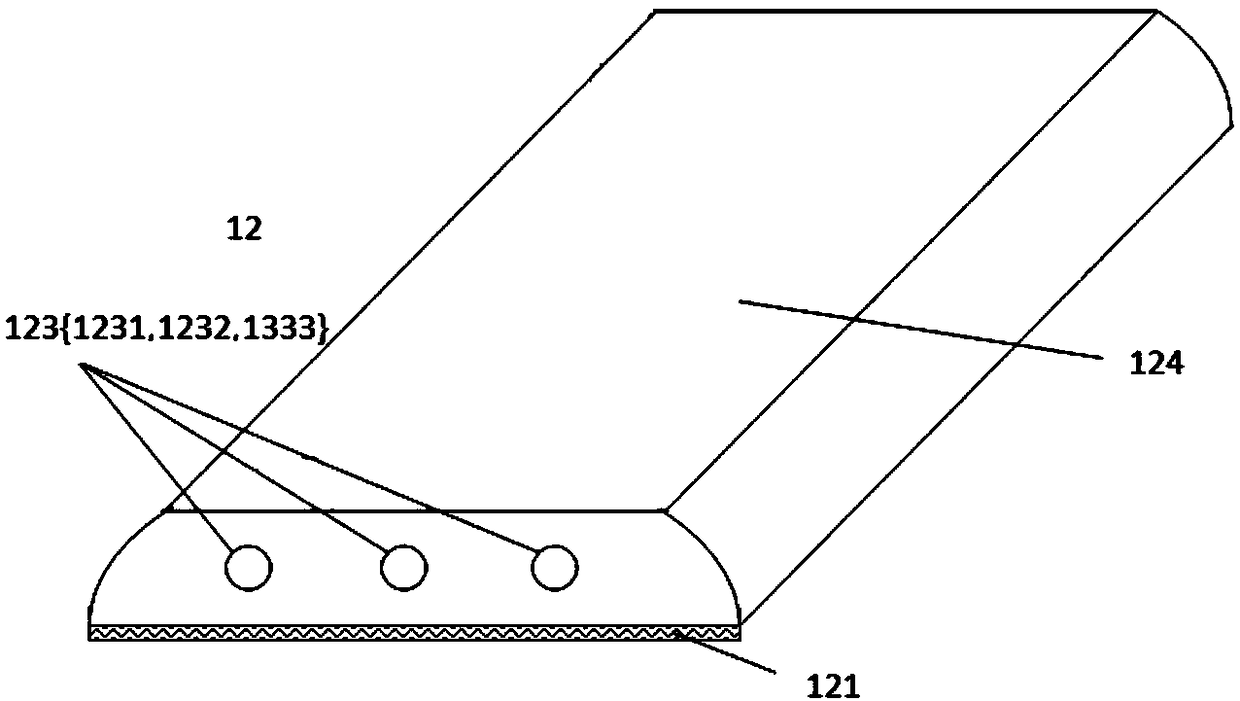

[0055] A portable cotton grade inspection device includes a box body 1, a telescopic rod 2, and a pull handle 3. The box body 1 is a cuboid structure, and when placed vertically, it is divided into an upper top, a bottom, a left side, a right side, a front side, and a back side, and its interior is a cavity. The box body 1 is the main structure of the testing equipment. A telescopic rod 2 is arranged on the back of the box body 1 , and the telescopic rod 2 can be stretched in the vertical direction, specifically, can extend to the top of the box body 1 . The end of the telescopic rod 2 is provided with a pull handle 3, the pull handle 3 is provided with a non-slip surface, and a grip part conforming to the contour of t...

Embodiment 2

[0076] This embodiment is carried out on the basis of the foregoing embodiment 1, and mainly introduces the inspection method using the portable cotton grade inspection equipment.

[0077] A kind of inspection method using portable cotton grade inspection equipment, described inspection method adopts portable cotton grade inspection equipment as described above, described inspection method comprises the following steps:

[0078] Step 1: moving the portable cotton grade testing equipment to a position to be tested;

[0079] Step 2: Put away the telescopic rod 2, and lay the cabinet 1 on the right side;

[0080] Step 3: Adjust the levelness of the box body 1 by adjusting the adjustment assembly 13 on the right side of the box body 1; specifically, by rotating the adjustment knobs on each adjustment piece, the horizontal air bubbles are centered;

[0081] Step 4: Open the closing part so that the front part opens slowly;

[0082] Step 5: Press the switch button of the light sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com