A Model Method for Optimizing Cement Raw Meal Quality

A technology for cement raw meal and optimization model, applied in the field of industrial Internet, can solve the problems of incomplete parameters, poor raw meal cycle and quality stability, difficulty, etc., and achieve the effect of high parameter adjustment efficiency, strong universality and stable quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

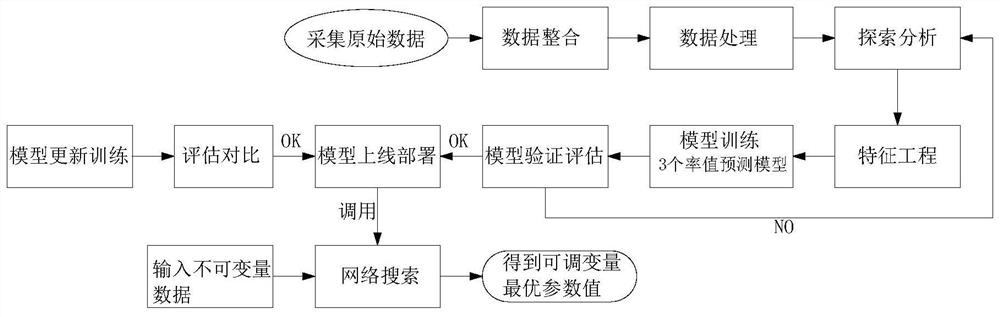

[0037] The present invention is a model method for optimizing the quality of cement raw meal. Based on the historical data of various parameters in the raw meal grinding process, an optimization model for the quality of cement raw meal is constructed, and the optimal parameter value is given through the model, so as to finally achieve qualified raw meal quality, Stablize. It consists of two stages, building a raw meal quality prediction model and building a raw meal ratio optimization model.

[0038] The construction of a raw meal quality prediction model includes the following steps:

[0039] S11. Collect the raw data of each parameter in the cement raw meal production process in the past year, including the proportion of CaO in the incoming limestone, the proportion of MgO in the incoming limestone, the moisture content of the incoming limestone, the particle size of the incoming limestone out of the crusher, and each auxiliary material ( SiO in fine sandstone, bauxite, iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com