Mechanical equipment multi-working-condition fault prediction method based on attention mechanism

A technology for mechanical equipment and fault prediction, applied in prediction, neural learning methods, instruments, etc., can solve problems such as time-consuming and labor-intensive, failure to find operating conditions, failure to make full use of sensor data time dependence, etc., to improve convergence Effects of Speed and Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

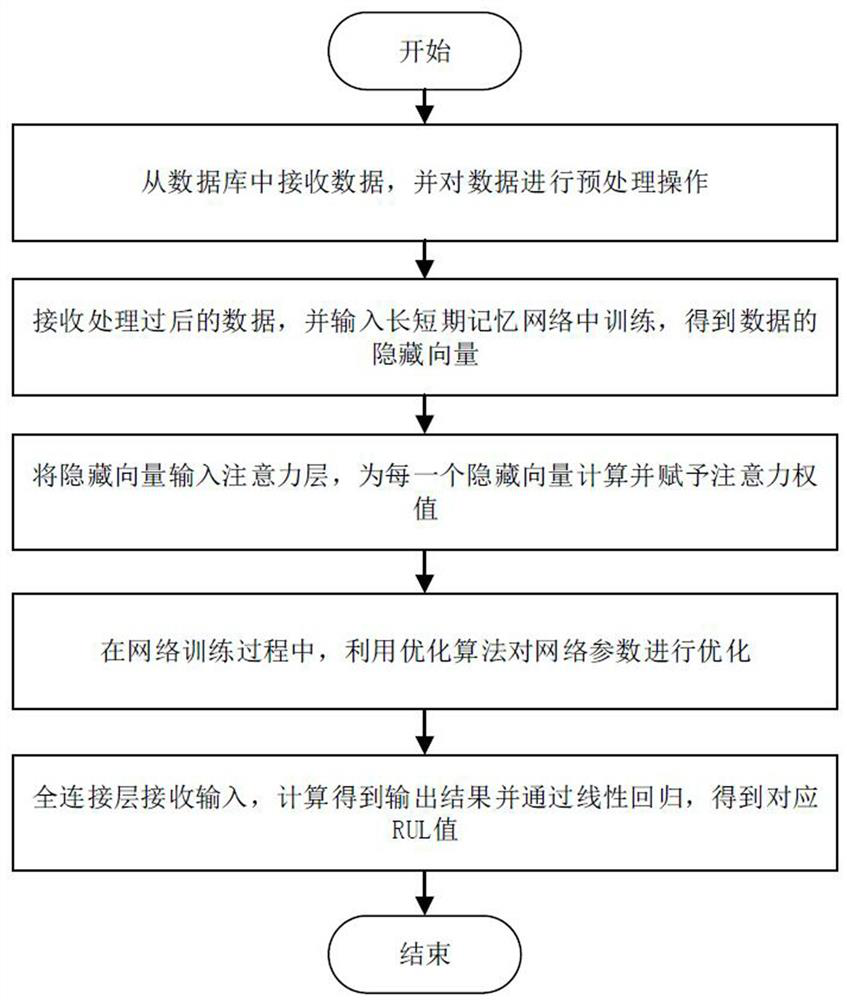

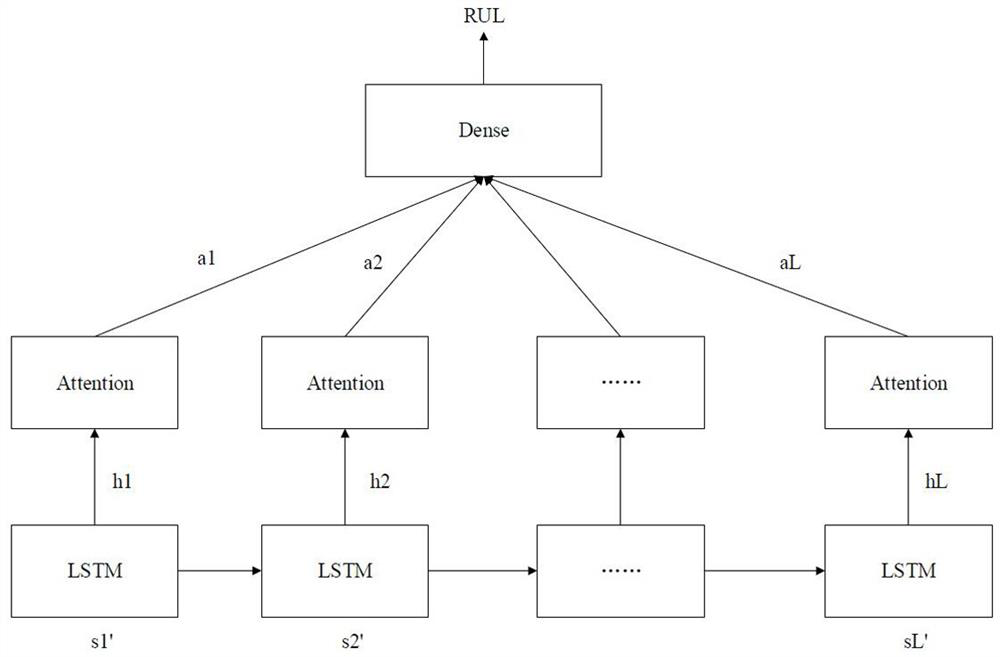

[0050] Such as Figure 1-2 As shown, this embodiment proposes a multi-condition fault prediction method for mechanical equipment based on the attention mechanism, including the following steps:

[0051] Step 1: Take out the original data from the database received and saved on the sensor, and preprocess the original data; first, receive the original data and vectorize it, recorded as T c is the failure cycle of the cth component, c∈{1,2,…,n}; each item is a K+1-dimensional vector {x 1 ,x 2 ,...,x k ,y i}, respectively represent k sensor input eigenvalues and corresponding RUL values; then normalize the data, the calculation formula is That is, the corresponding normalized value of each item in S is Finally, the data is time-divided to form sliding time window data, that is, O={o i |i>=0, ic -L}, where o i =s i 'The window length is L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com