Auxiliary oil injection device for transformer

An oil injection device and transformer technology, applied in transformer/inductor parts, transformer/inductor cooling, electrical component structure association, etc., can solve the problems of transformer lack of oil automatic alarm system, electrical component damage, difficult oil injection, etc. , to achieve the effects of being widely used, realizing automatic control, and saving oiling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

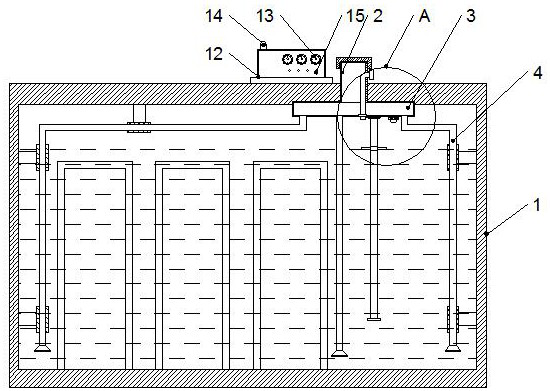

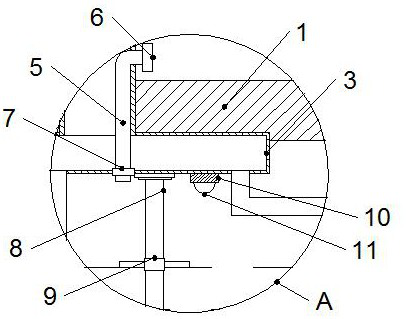

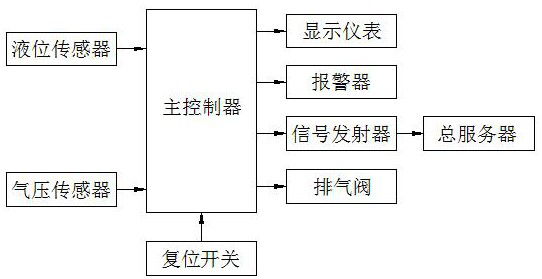

[0019] Example: such as Figure 1-3 As shown, the present invention is an auxiliary oiling device for a transformer, including a transformer body 1 and an auxiliary oiling device, the top of the transformer body 1 is provided with an oiling port 2, and the auxiliary oiling device includes a splitter box 3 and a control box 12 , the splitter box 3 is fixedly installed at the bottom of the oil filling port 2, and is connected with the oil filling port 2. The bottom of the splitter box 3 is connected with a number of shunt pipes 4, and the other ends of the shunt pipes 4 are all downward set, and are all arranged close to the bottom surface of the transformer body 1, the bottom of the splitter box 3 is vertically fixed with a guide rod 8, and a float type liquid level sensor 9 is installed on the guide rod 8, and the splitter box 3 A fixed base 10 is fixedly installed on the side close to the connection of the guide rod 8, and an air pressure sensor 11 is fixedly installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com