Multi-metal composite oxide coated lithium-rich manganese-based positive electrode material and preparation method thereof

A composite oxide, lithium-rich manganese-based technology, used in positive electrodes, active material electrodes, nanotechnology for materials and surface science, etc., can solve problems such as unevenness, fragmentation, secondary particle cracks, etc. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

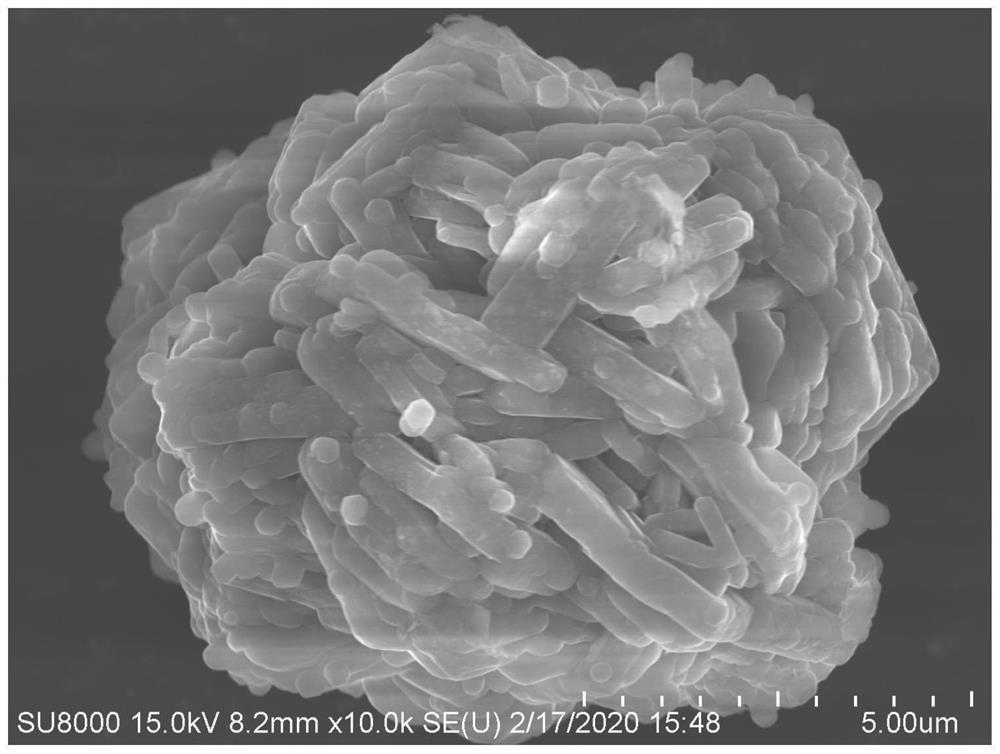

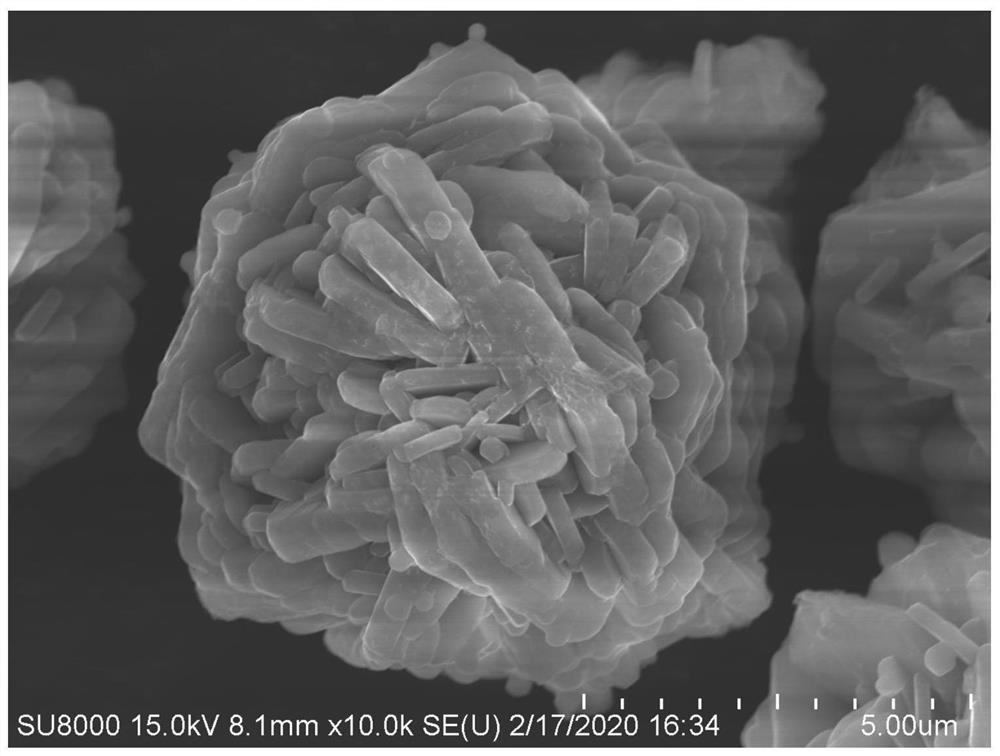

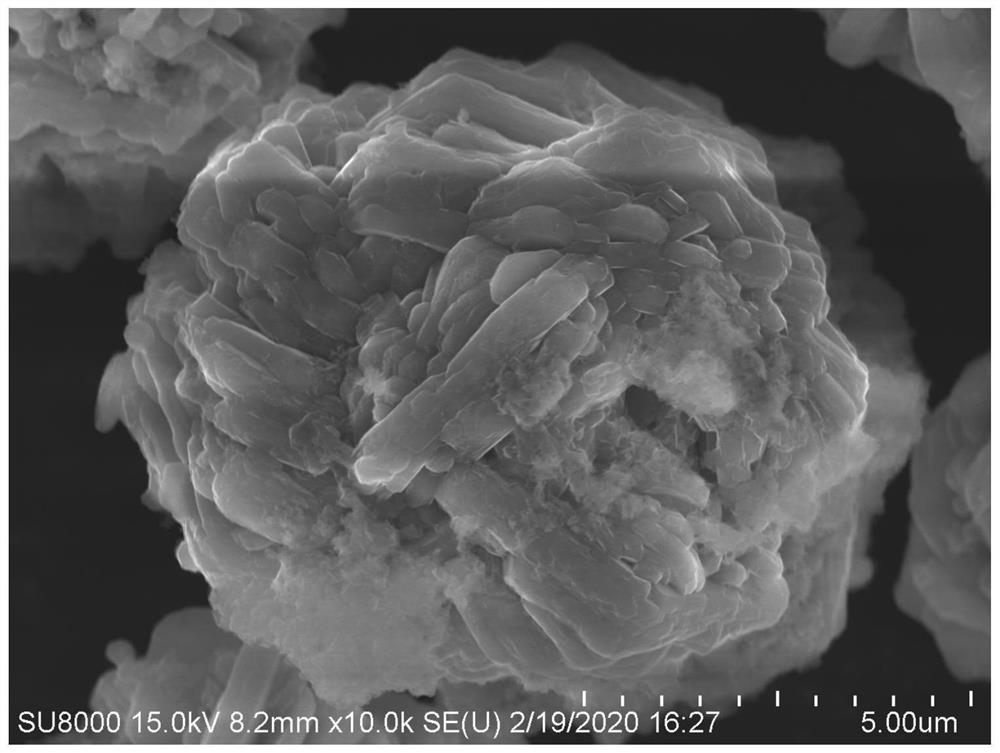

Image

Examples

Embodiment 1

[0046] A method for preparing a multi-metal composite oxide-coated lithium-rich manganese-based positive electrode material of the present invention, the specific steps are as follows:

[0047] (1) Metal powders of 500nm gadolinium (Gd), niobium (Nb), zirconium (Zr) and strontium (Sr) (n(Gd):n(Nb):n(Zr):n(Sr)=0.05 :0.5:0.5:0.5) was added into hydrochloric acid with a concentration of 0.5mol / L, mechanically stirred for 3 hours, and the rotating speed of the mechanically stirred was 300r / min. After stirring, the solution was filtered, and the filter residue was vacuum-dried in a vacuum oven. The temperature is 80°C, and the drying time is 5.0h to obtain pre-activated metal powder;

[0048] (2) Add the pre-activated metal powder and urea-formaldehyde resin obtained in step (1) into 2mol / L lithium nitrate aqueous solution for reaction, the reaction temperature is 80°C, and the reaction time is 5h. After the reaction is completed, use an ultrasonic cell disruptor (ultrasonic power...

Embodiment 2

[0060] A method for preparing a multi-metal composite oxide-coated lithium-rich manganese-based positive electrode material of the present invention, the specific steps are as follows:

[0061] (1) Metal powders of 700nm gadolinium (Gd), niobium (Nb), zirconium (Zr) and strontium (Sr) (n(Gd):n(Nb):n(Zr):n(Sr)=0.05 :0.5:0.5:0.5) was added into nitric acid with a concentration of 0.6mol / L and carried out mechanical stirring for 4h, the rotating speed of mechanical stirring was 250r / min, filtered, and the filter residue was vacuum-dried in a vacuum oven at a drying temperature of 90°C. The time is 7.0h, and the metal powder of preactivation treatment is obtained;

[0062] (2) Add the pre-activated metal powder and urea-formaldehyde resin obtained in step (1) into 1mol / L lithium acetate aqueous solution for reaction, the reaction temperature is 110°C, and the time is 3h; after the reaction is completed, use an ultrasonic cell disruptor to disperse After 3 hours (the ultrasonic po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap