A Rotationally Excited Friction-Piezoelectric Composite Generator

A piezoelectric composite, generator technology, applied in the direction of friction generators, generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve the friction and wear between friction pairs of sliding friction generators, Vibration frequency and rotating body speed adaptability are low, power generation capacity and energy density per unit volume are low, etc., to achieve the effect of strong speed adaptability, simple structure and excitation process, and avoid surface friction and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

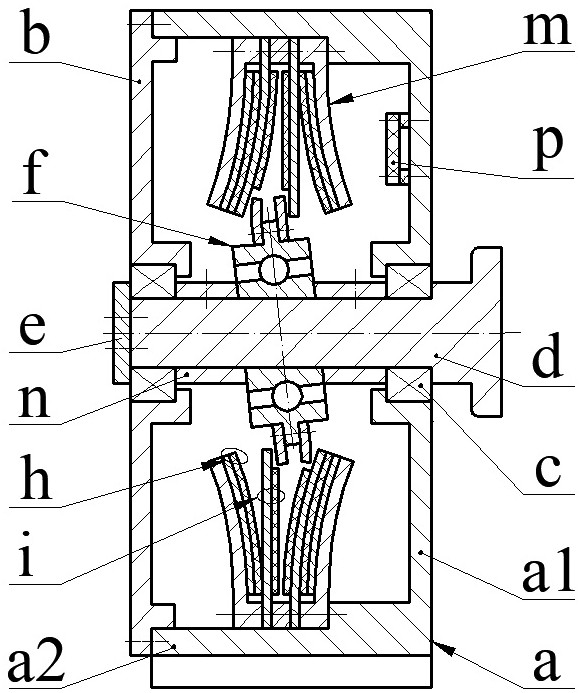

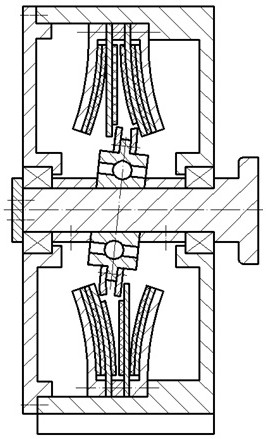

[0021] The composite generator proposed by the present invention mainly includes a casing a, a bearing c, an end cover b, a rotating shaft d, a shaft sleeve n, an exciter f equipped with a plectrum j, a bracket m, a composite film h, and a piezoelectric vibrator i and circuit board p. The end cover b is installed on the end of the casing a2 of the casing a through screws, the rotating shaft d is installed on the end cover b and the bottom a1 of the casing a through the baffle e and the bearing c, and the bearing c is connected through the baffle e and the rotating shaft d The shaft shoulder is positioned, and the block e is installed on the end of the rotating shaft d without the shoulder through a screw.

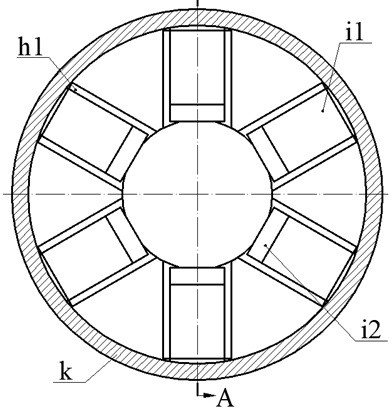

[0022] The swing ring f2 of the exciter f is set on the fixed ring f1 through the rolling body f3. The rolling body f3 is a ball or a cylinder. The angle Q between the fixed ring axis x1 and the swing ring axis x2 in the same plane is called the shaft inclination angle. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com