Printing and dyeing stirring device based on multi-axis motion principle and stirring method of device

A technology of multi-axis motion and stirring device, applied in the field of printing, dyeing and textile, can solve the problems of unsatisfactory mixing and stirring effect, low stirring efficiency, etc., and achieve the effect of strengthening mixing and stirring efficiency, good stirring and mixing effect, and high-efficiency mixing and stirring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

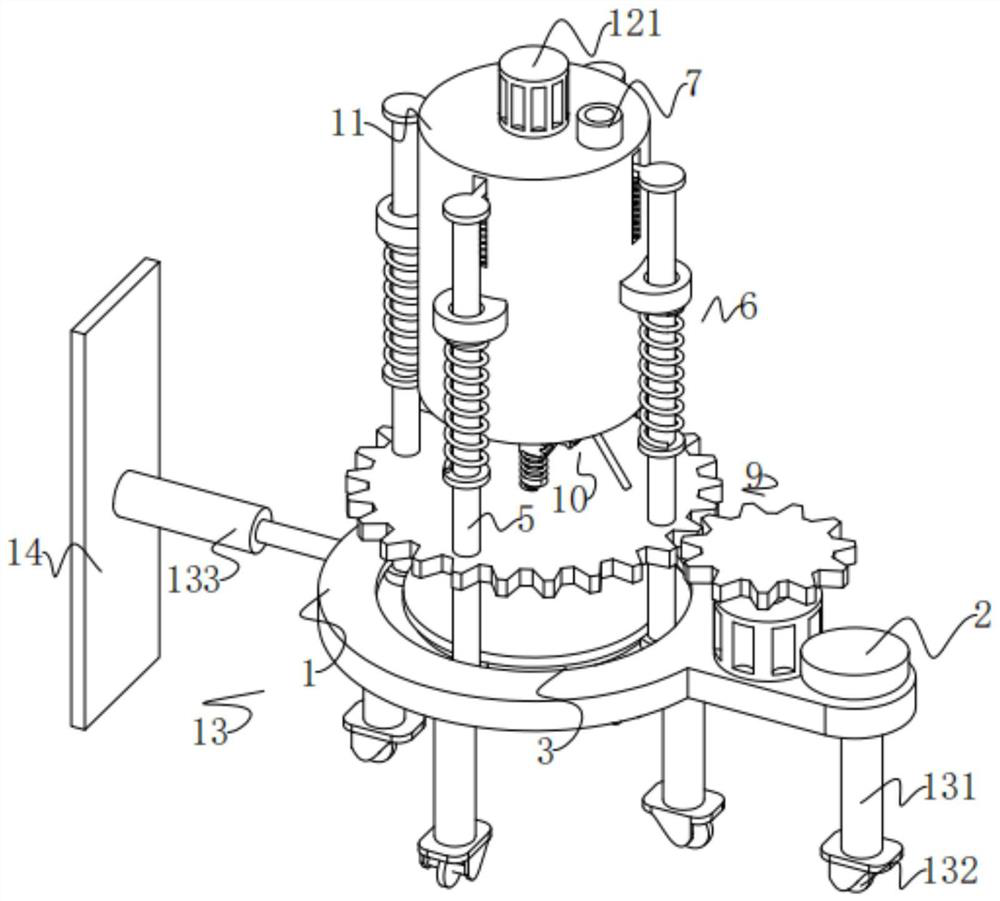

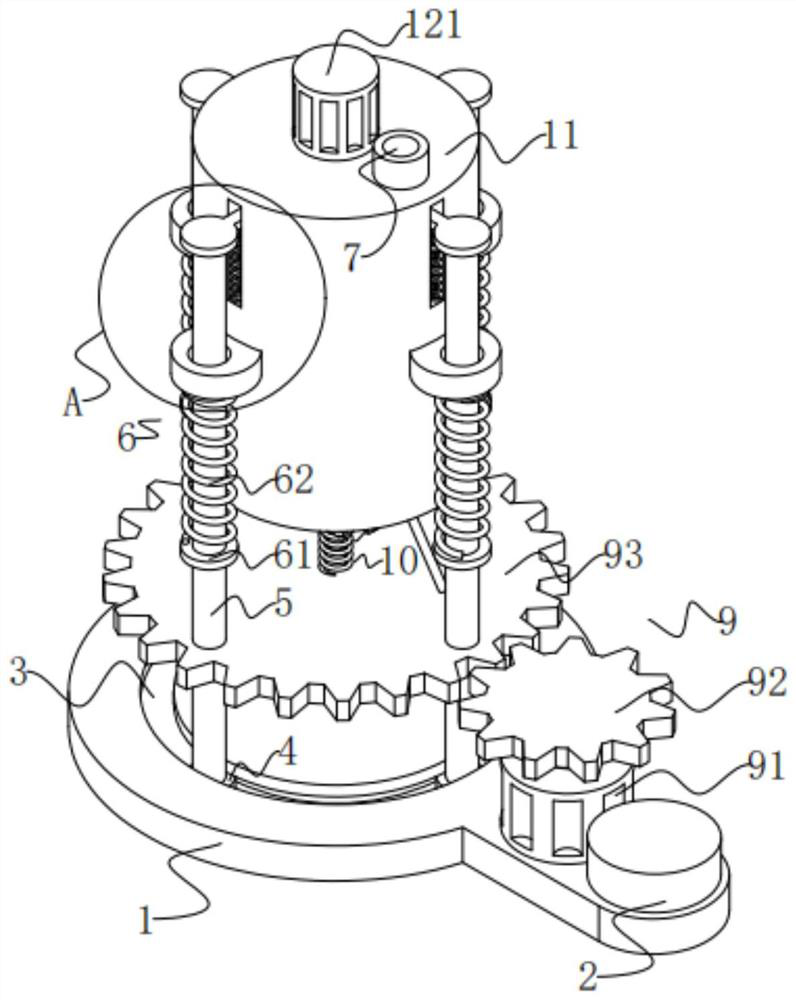

[0061] see Figure 1-8 as well as Figure 13 , a printing and dyeing agitating device based on the principle of multi-axis motion, including a mixing drum 11, a feeding port 7 and a feeding port 8 are fixedly arranged on the mixing drum 11, and a valve is installed on the feeding port 8, specifically, the feeding The port 7 is arranged at the top eccentric part of the mixing drum 11 and communicates with it, and the discharge port 8 can be arranged at the bottom eccentric part of the mixing drum 11 or at the lower position of the circumferential surface of the mixing drum 11, so as to realize feeding and Discharging, the present invention also includes:

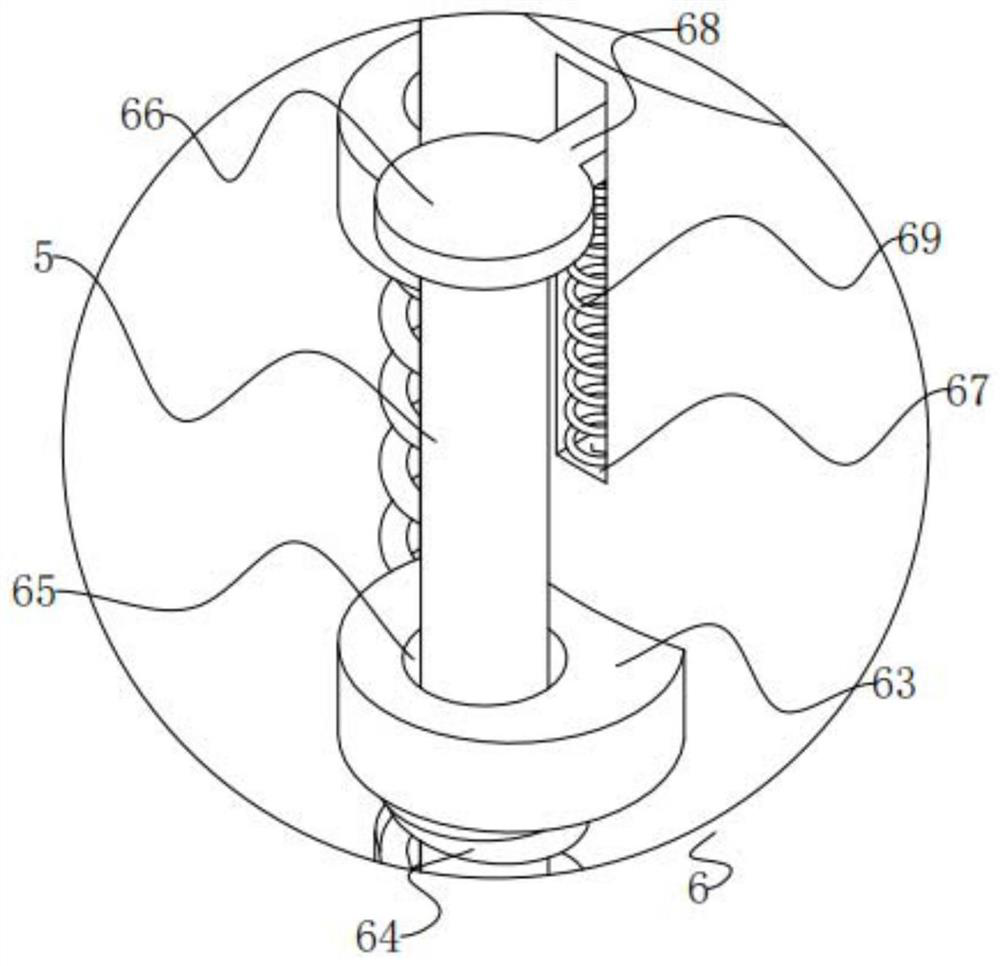

[0062] The base 1 arranged on the lower side of the mixing drum 11, the top of the base 1 is provided with an annular T-shaped limit rotation groove 3, and the inner wall of the annular T-shaped limit rotation groove 3 is slidably connected with a plurality of equidistant rotating blocks 4 , the tops of a plurality of rotat...

Embodiment 2

[0075] The structure of embodiment 1 is exactly the same as that of embodiment 2, the difference is that the braking of the second forward and reverse motor 105 in embodiment 2 is reverse braking: reverse braking of the second forward and reverse motor 105, the second The output end of the reversing motor 105 rotates counterclockwise to drive the missing gear 106 to rotate counterclockwise, thereby realizing the upward movement of the mixing drum 11 through the intermittent meshing transmission between the missing gear 106 and the rack support block 103. At this time, the third spring 102 1. Both the first spring 62 and the second spring 69 are stretched. When the missing gear 106 is no longer engaged with the rack support block 103, the third spring 102, the first spring 62 and the second spring 69 will reset from the stretched state. , and at the same time cooperate with the mixing drum 11 and the effect of the gravity of the printing and dyeing raw materials, so as to realiz...

Embodiment 3

[0077] see figure 1 -5 and Figure 9 -13, the difference between embodiment 3 and embodiment 1 and embodiment 2 is that embodiment 3 replaces the reciprocating movement of the third forward and reverse motor 121 set in the PLC controller 2 by the signal stop mechanism. The program also includes a signal control mechanism, the signal stop mechanism includes a first waterproof contact switch 1220, a second waterproof contact switch 1221, a third waterproof contact switch 1222 and a fourth waterproof contact switch 1223, and the first waterproof contact switch 1220, the second waterproof contact switch The second waterproof contact switch 1221, the third waterproof contact switch 1222 and the fourth waterproof contact switch 1223 are all electrically connected to the PLC controller 2, the first waterproof contact switch 1220 is fixedly arranged on the top of the second coupling 126, and the third waterproof contact switch The contact switch 1222 is fixedly arranged at the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com