Plane grinding equipment with rotating mechanism

A technology of rotating mechanism and surface grinding, which is applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machine tool parts, etc. It can solve the problems of inconvenient workpiece fixing, workpiece cannot be rotated, and workpiece cannot be effectively polished. Achieve the effect of convenient operation, improved grinding efficiency and convenient fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

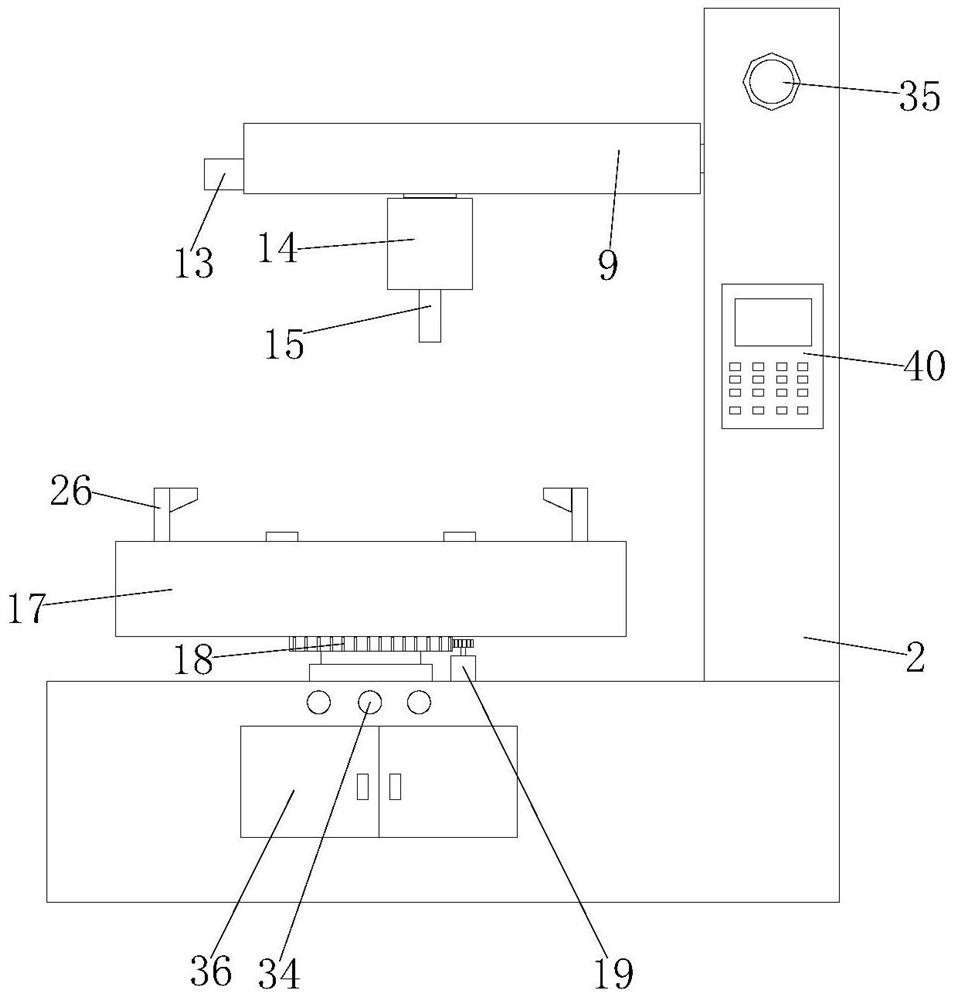

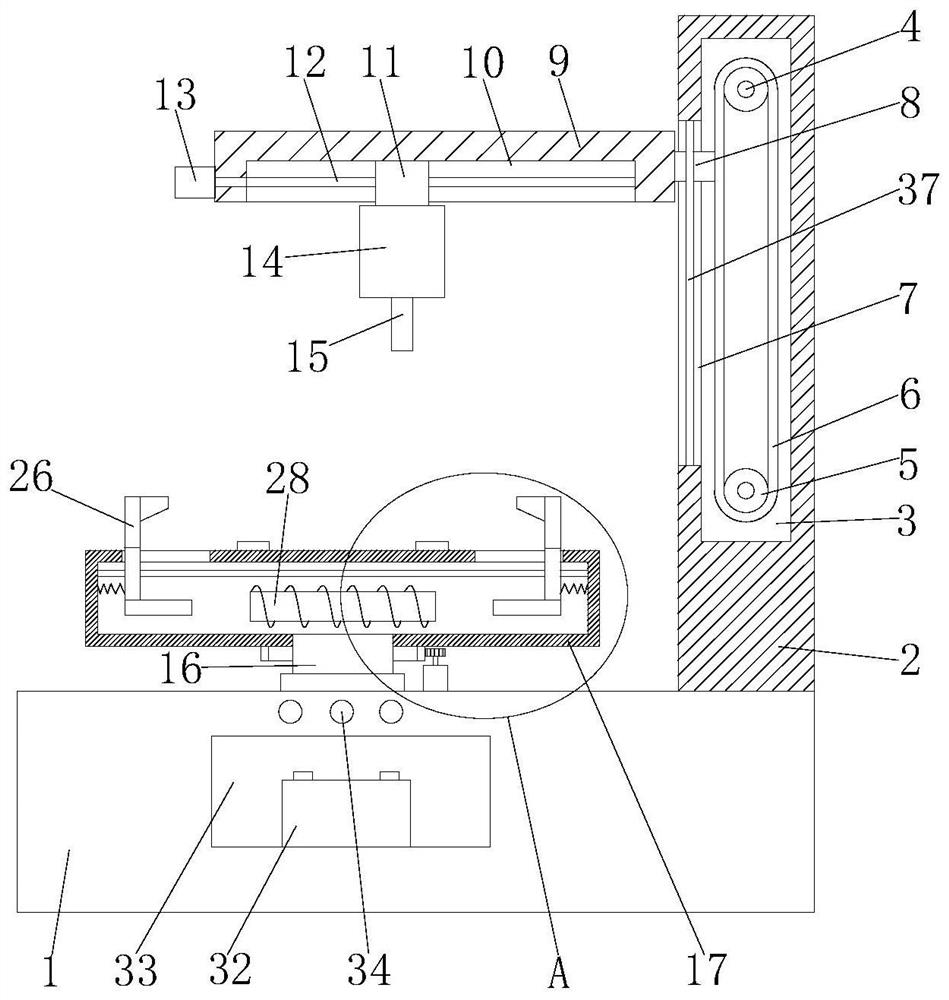

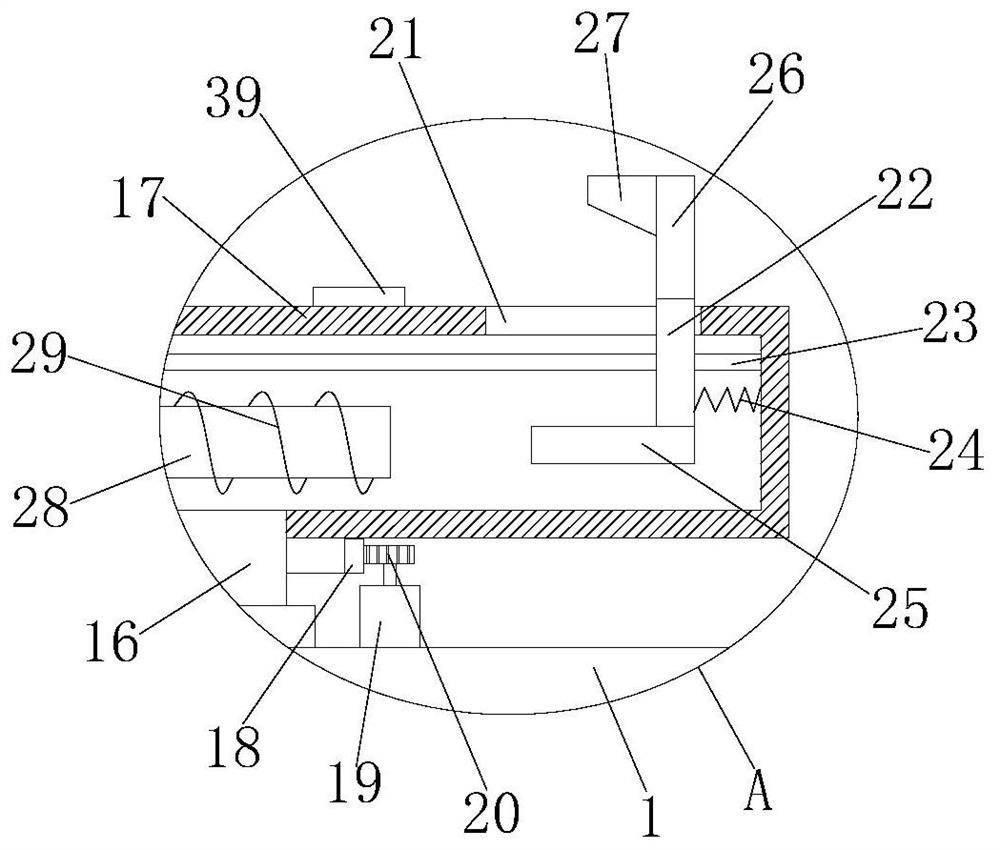

[0030] refer to Figure 1-6 , a surface grinding equipment with a rotating mechanism, including a workbench 1, a vertical plate 2 on the top of the workbench 1, a vertical cavity 3 is opened on the vertical plate 2, a lifting structure is arranged in the vertical cavity 3, and a sliding structure is connected to the lifting structure. Block 8, on the sliding block 8, the horizontal plate 9 is fixedly installed, and the bottom of the horizontal plate 9 is slidably equipped with a grinding motor 14, and the grinding motor 14 is connected with a grinding head 15, and the horizontal plate 9 is connected with an adjustment mechanism, and the adjustment mechanism and the grinding motor 14 connection, a metal pipe 16 is rotatably connected to the workbench 1, and a disk box 17 is fixedly installed on the top of the metal pipe 16. A rotating structure is arranged on the top of the workbench 1. An electromagnet 28 is arranged inside, and a wire 29 is wound on the outside of the electro...

Embodiment 2

[0041] refer to Figure 1-6 , a surface grinding equipment with a rotating mechanism, including a workbench 1, a vertical plate 2 on the top of the workbench 1, a vertical cavity 3 is opened on the vertical plate 2, a lifting structure is arranged in the vertical cavity 3, and a sliding structure is connected to the lifting structure. block 8, on the sliding block 8, a transverse plate 9 is fixedly installed by welding, and a grinding motor 14 is slidingly installed on the bottom of the transverse plate 9, and a grinding head 15 is connected on the grinding motor 14, and the grinding head 15 can be easily replaced. There is an adjustment mechanism, the adjustment mechanism is connected with the grinding motor 14, the metal pipe 16 is connected with the rotation on the workbench 1, the top of the metal pipe 16 is fixedly installed with the disc box 17 by welding, the top of the workbench 1 is provided with a rotating structure, and the rotating structure Connect with the disc b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com