Method for improving chromium oxide green color

A chromium oxide, green technology, applied in the direction of chromium oxide/hydrate, etc., can solve the problems of high roasting temperature, high energy consumption, complicated preparation method, etc., and achieve the effect of improving color, color saturation and reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

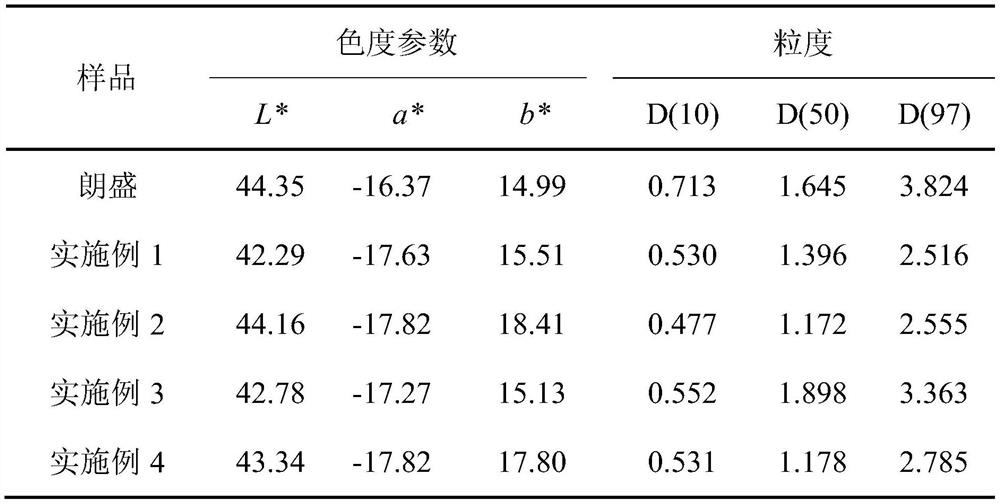

Examples

Embodiment 1

[0065] The present embodiment provides a method for improving the green color of chromium oxide, said method comprising the following steps:

[0066] Mix 1000g of sodium dichromate, 161g of sulfur, 20g of urea, 18g of cornstarch and 12g of boric acid and place them in an electric heating roaster, and pass through 1.0m 3 The air was roasted at 1000°C for 2 hours. During the roasting process, the concentration of oxygen in the roasting tail gas was controlled to be 15vol.%. After slurry washing, suction filtration, drying and ball milling, the chromium oxide green product is obtained.

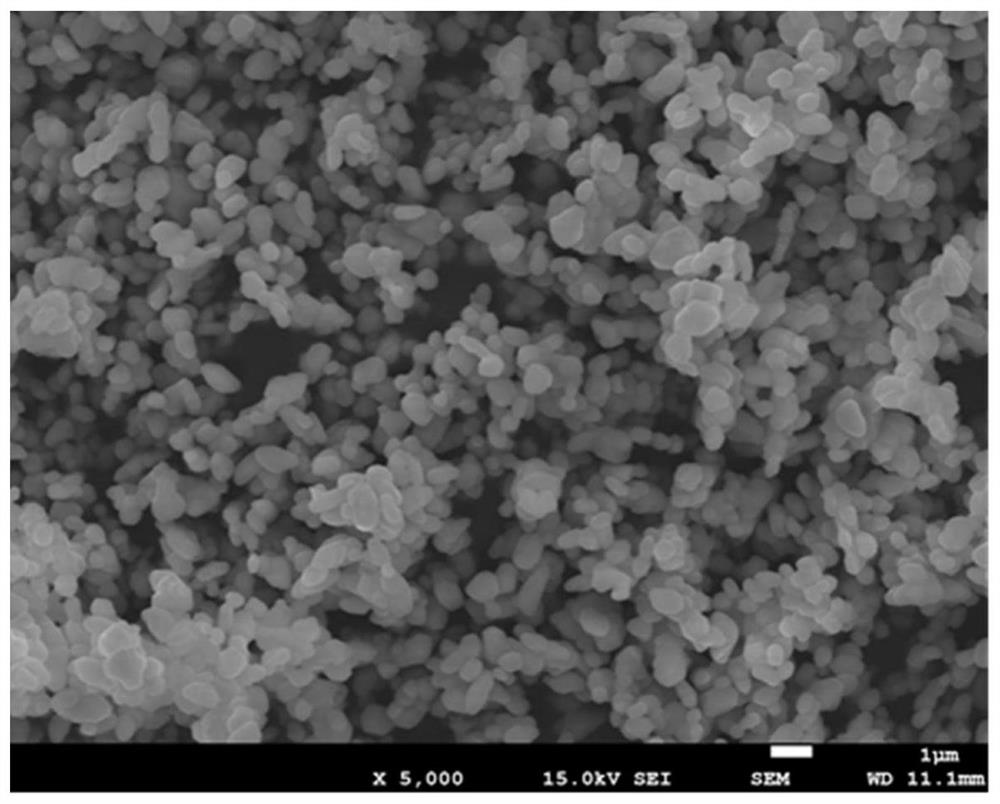

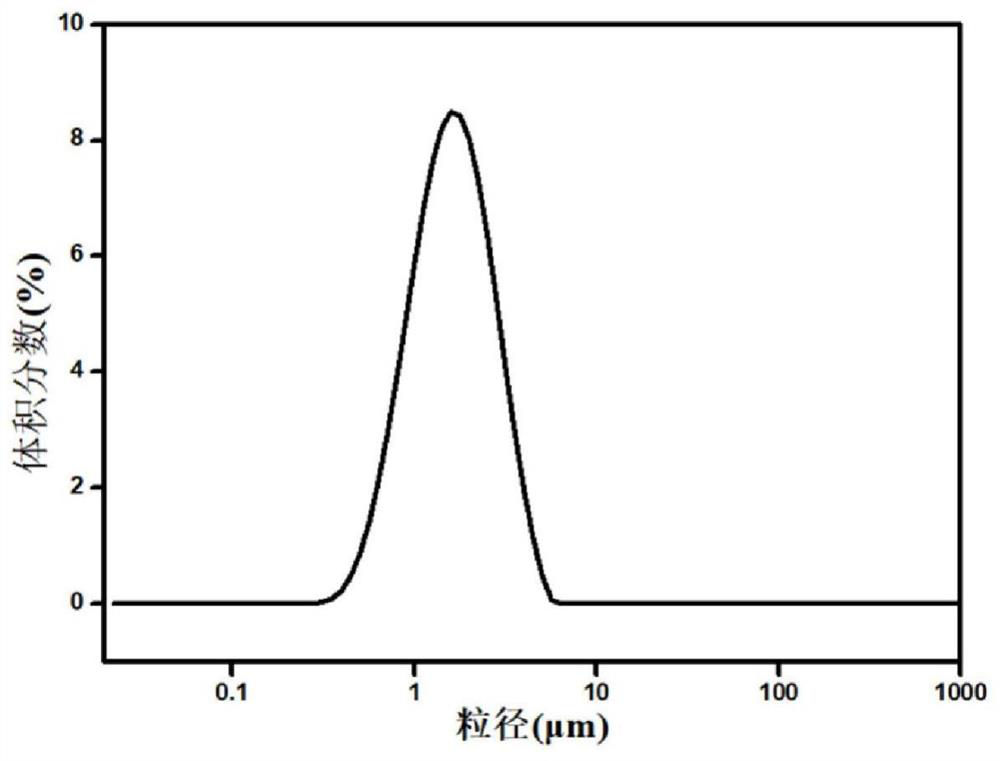

[0067] In the present embodiment, the prepared chromium oxide green product is subjected to SEM characterization, and its SEM image is as follows figure 1 Shown; The particle size distribution figure of described chromium oxide green product is as figure 2 shown.

[0068] Depend on figure 1 It can be seen that the particle size of the chromium oxide green product is uniform, and the grain si...

Embodiment 2

[0071] The present embodiment provides a method for improving the green color of chromium oxide, said method comprising the following steps:

[0072] Mix 500kg of sodium dichromate, 375kg of ammonium sulfate and 35kg of cassava starch and place them in a rotary roasting kiln, passing through a 41.5m 3 Oxygen was roasted at 900°C for 2 hours. During the roasting process, the concentration of oxygen in the roasting tail gas was controlled to be 13vol.%. The solid product obtained after roasting was cooled to 300°C with the furnace, and then poured into 2250L of water, and then passed through slurry After chemical washing, centrifugal separation, drying and jet crushing, the chromium oxide green product is obtained.

Embodiment 3

[0074] The present embodiment provides a method for improving the green color of chromium oxide, said method comprising the following steps:

[0075] Mix 1000g of potassium dichromate, 140g of sulfur and 18g of ammonium sulfate, place them in an electric heating roaster, and pass through 0.023m3 Oxygen was roasted at 950°C for 1.5h. During the roasting process, the concentration of oxygen in the exhaust gas was controlled to be 12vol.%, and the solid product obtained after roasting was cooled to 300°C with the furnace, and then poured into 4.5L of water. The chromium oxide green product is obtained after slurry washing, plate-and-frame filter pressing, drying, and mill grinding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com