Composite electrical contact

An electrical contact, composite technology, applied in the direction of contacts, circuits, electrical switches, etc., can solve problems such as insignificant effects, and achieve the effect of eliminating contact bounce and improving elastic deformation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

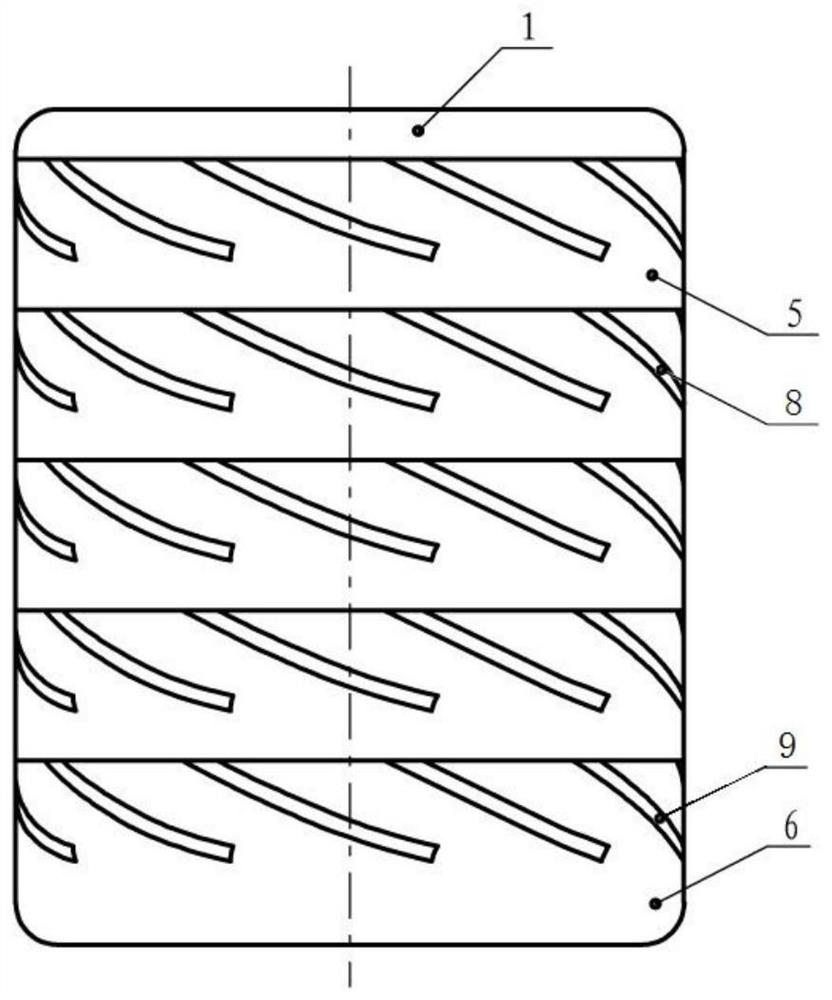

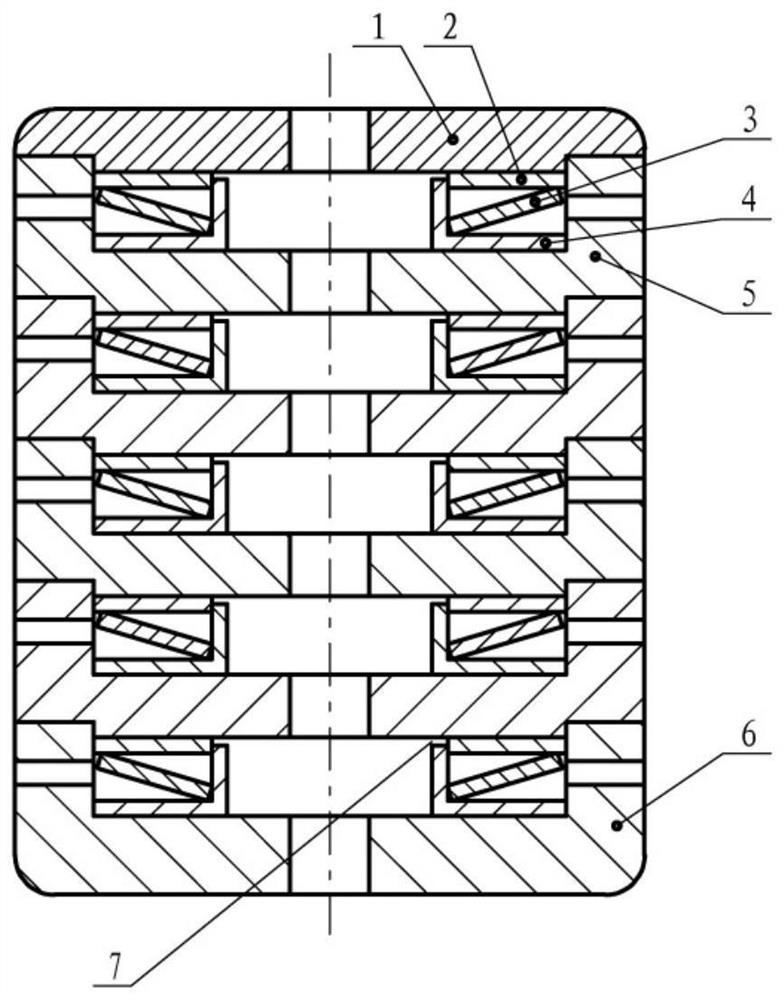

[0034] Such as Figure 1-3 As shown, the composite electrical contact includes successively arranged contact pieces 1, at least one middle cup holder 5, and a rear cup holder 6, and the inner cavity of the middle cup holder 5 and the tail cup holder 6 All are provided with an elastic support structure, the elastic support structure includes a positioning washer 4, and the positioning washer 4 passes through the disc washer 3 and the support washer 2 in turn, and the support washer 2 is arranged in the contact sheet 1 and the center Place the lower surface of the cup holder 5, the positioning gasket 4 is arranged on the upper surface of the central cup holder 5 and the tail cup holder 6, the upper surface of the positioning gasket 4 is connected with the contact piece 1 and the lower surface of the central cup holder 5 There is a stop gap 7.

[0035] The disk washer 3 in the elastic support structure is compressed to generate a rebound force opposite to the direction of motion...

Embodiment 2

[0064] The difference with embodiment 1 is:

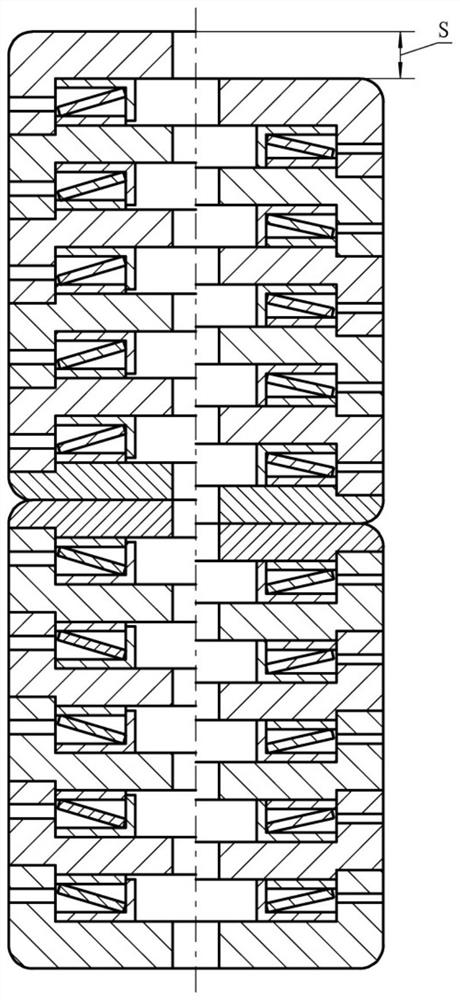

[0065] Such as Figure 4-5 As shown, in order to reduce the mass of the moving part of the vacuum interrupter and reduce the kinetic energy, the moving-end composite electrical contact and the static-end composite electrical contact adopt different configurations. Specifically, the contact piece 1, the middle cup holder 5 and the tail cup holder 6 of the moving-end compound electric contact are all one; the contact piece 1 and the tail cup holder 6 of the static-end composite electric contact All are 1, and the center cup holder 5 is 2. Each of the central cup holder 5 and the rear cup holder 6 is provided with a support gasket 2, a dish washer 3, a positioning gasket ring 4, and a stop gap 7 each.

[0066] In this embodiment, the closing speed of the fast switch is v=1.6m / s, the contact pressure is f=2500N, and the mass of the moving part of the vacuum interrupter is m=0.5kg. From the acceleration formula f=ma, calculate a=5000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com