Fan-type spliced knitted fabric and knitting method and application thereof

A technology for knitted fabrics and fabrics, applied in the field of knitted fabrics, can solve the problems of sawtooth effect, affect appearance, limit shoe upper design, etc., and achieve the effect of eliminating sawtooth structure and improving ductility and comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

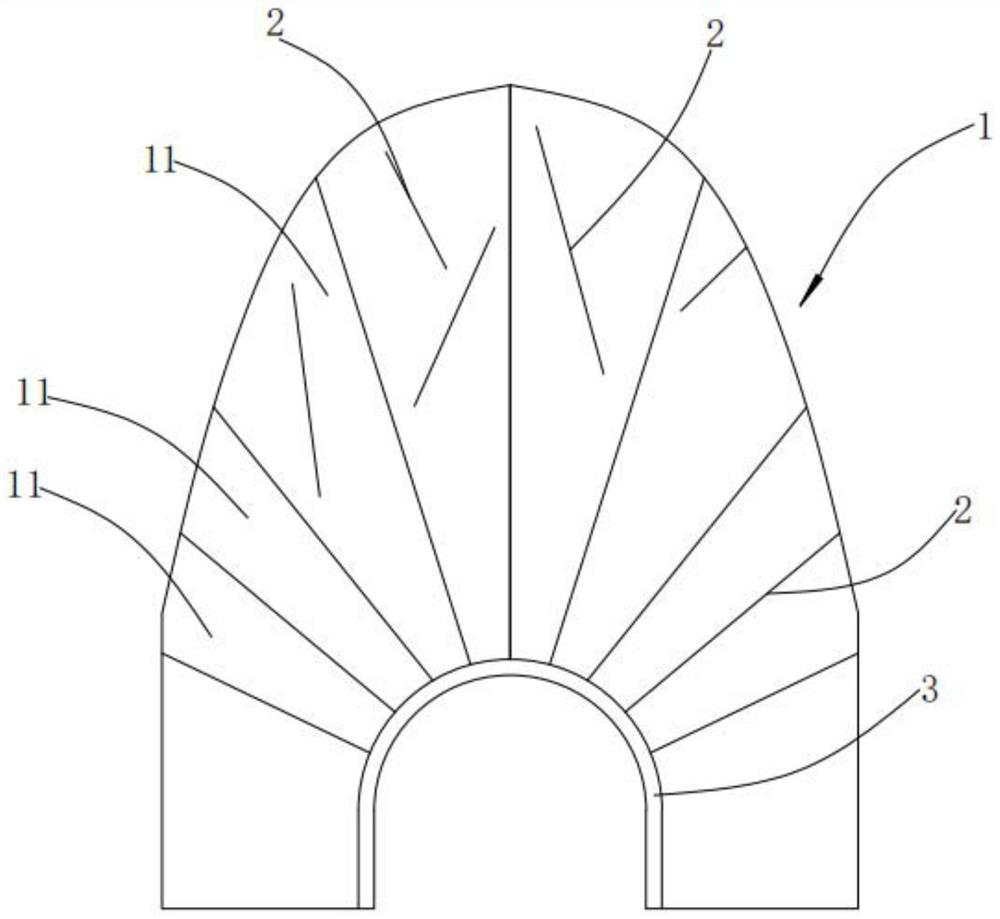

[0048] Embodiment 1: In this embodiment, a three-dimensional structure is woven in the independently woven fabric 11.

Embodiment 1

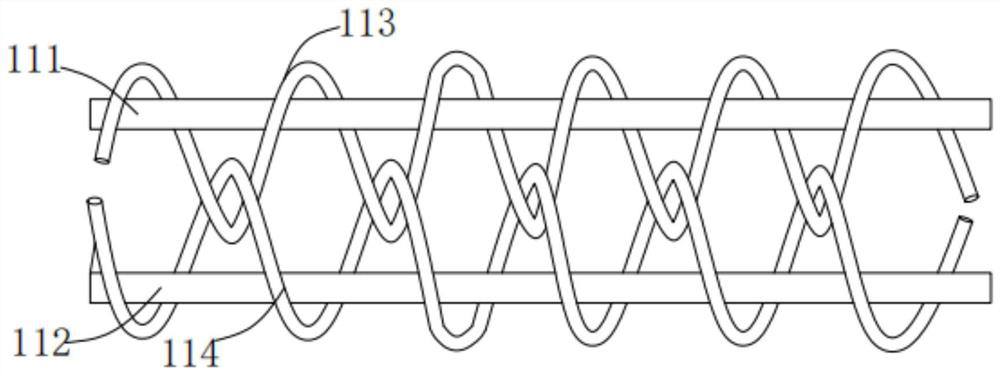

[0050] refer to figure 2 , in this embodiment, the independently woven fabric 11 comprises a face weave layer 111, a first middle layer 113, a second middle layer 114 and a bottom weave layer 112, and the knitting structure between the first middle layer 113 and the second middle layer 114 The knitting structure of the first middle layer 113 is connected with the face weaving layer 111 , and the weaving structure of the second middle layer 114 is connected with the bottom weaving layer 112 . The first intermediate layer 113 and the second intermediate layer 114 are interwoven to form a three-dimensional structure, so that the entire independently woven fabric 11 presents a three-dimensional effect, wherein the first and second intermediate layers 114 are connected by elastic yarn cross-knit connecting tissue, using yarn Carry out surface knitting and bottom tuck knitting to form surface knitting layer 111; utilize yarn to carry out bottom knitting to form bottom knitting laye...

Embodiment approach 2

[0051] Embodiment 2: In this embodiment, the independent woven fabric 11 does not have a woven three-dimensional structure.

[0052] Example 1

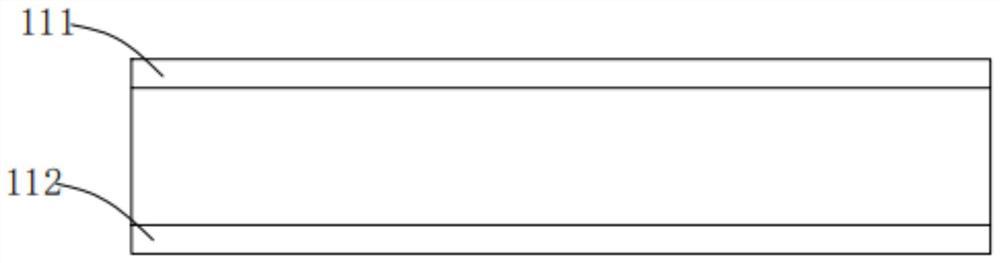

[0053] In this embodiment, the independently woven fabric 11 includes a surface knitting layer 111 and a bottom knitting layer 112 , and the knitting structure of the surface knitting layer 111 is connected to the bottom knitting layer 112 . The surface braided layer 111 and the bottom braided layer 112 are all woven from colored high-elastic yarns. For specific weaving methods, refer to Image 6 , the first knitting row is A yarn for top knitting and top knitting bottom tuck knitting. The second weaving row is B yarn for bottom knitting. The top tuck and bottom tuck knitting of the 1st and 2nd knitting rows and the 4th knitting needle column play the role of strengthening the connection with the C yarn. The knitting actions and functions of the 3rd and 4th knitting lines are consistent with those of the 1st and 2nd knitting lines....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap