Efficient chemical mixing device

A mixing device and chemical technology, applied in the field of high-efficiency chemical mixing devices, can solve the problems of low mixing efficiency, single operation mode, general material mixing effect, etc., and achieve the effect of improving the mixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

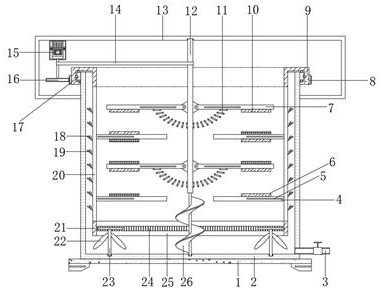

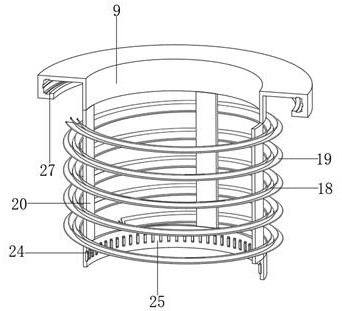

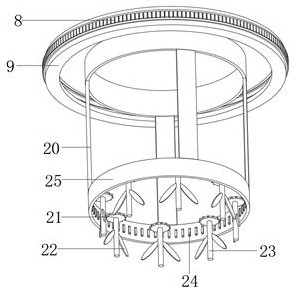

[0030] refer to Figure 1-4 , a high-efficiency chemical mixing device, comprising a base 1 with legs welded at the four corners of the bottom outer wall, a mixing box 2 fixed on the top outer wall of the base 1 by bolts, and a reinforcing ring plate 17 welded on the peripheral outer wall of the mixing box 2 near the top , and the outer wall of the reinforcing ring plate 17 is clamped with a supporting ring 9, and the opposite side of the supporting ring 9 and the reinforcing ring plate 17 is provided with an annular groove 27, and the inner walls of the corresponding two annular grooves 27 are rollingly connected with equidistantly distributed The four corners of the outer wall of the ball and the bottom of the support ring 9 are vertically welded with a fixed lever 4, and the outer wall of the mixing box 2 near the top is welded with a fixed frame 13, and the central axis of the top of the fixed frame 13 is connected with a rotating column 12 through a bearing rotation. , th...

Embodiment 2

[0041] refer to Figure 5 , a high-efficiency chemical mixing device. Compared with Embodiment 1, this embodiment also includes a swing rod 7 and one end of the top outer wall of the fixed driving rod 4. A collection tube 29 is welded, and the collection tube 29 is fixedly connected with a dial tube 28. .

[0042] When the present invention is in use: Utilize the collection cylinder 29 and the dial cylinder 28 arranged on the swing rod 7 and the fixed glass rod 4, during the rotation process of the swing rod 7 and the fixed dial rod 4, the material is first drummed into the dial cylinder 28, And in the collection barrel 29 to achieve collection, impact, to achieve the purpose of further improving the mixing effect of materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com