High-pressure multi-surface rotary-table jet cleaning device with compensation mechanism

A technology of compensation mechanism and cleaning device, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., which can solve the problems of low processing efficiency, long use time, manual replacement of nozzles, etc., and improve the use of Long life, high working efficiency, and the effect of avoiding water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

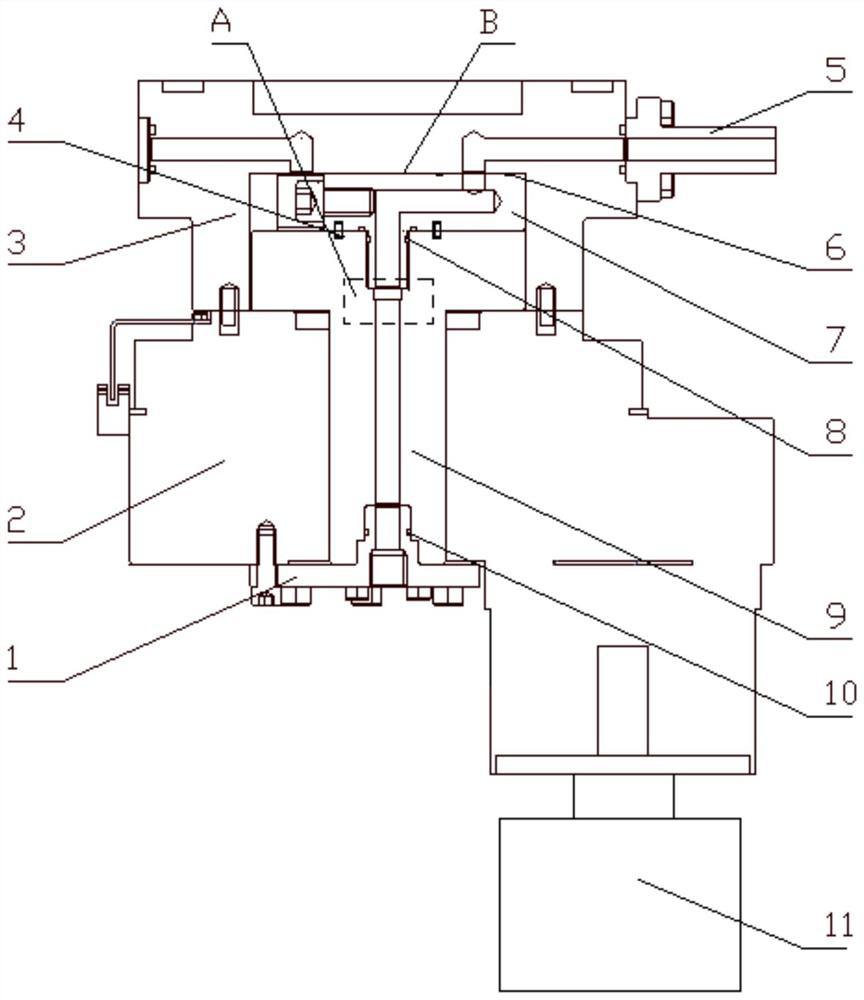

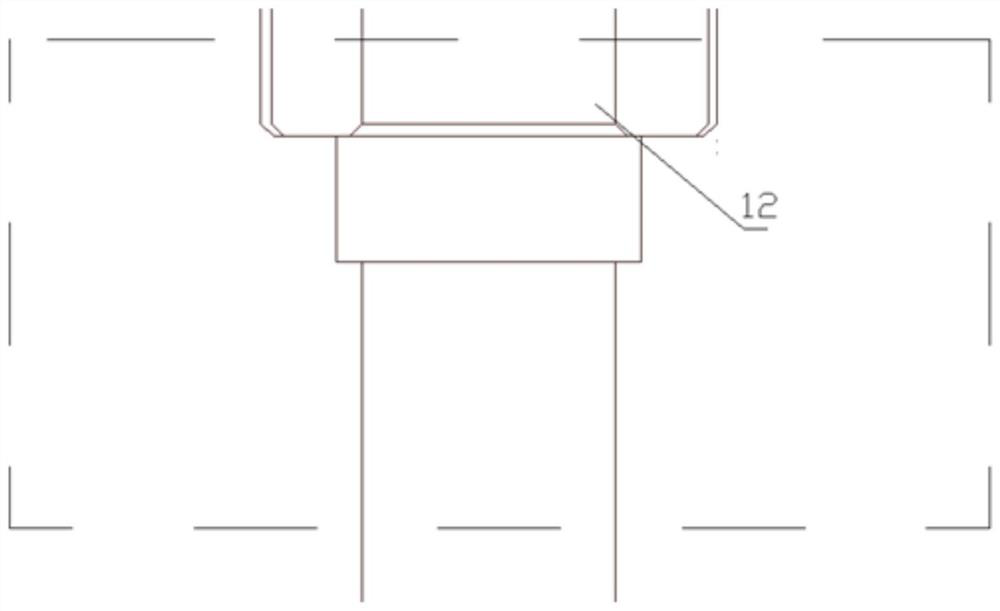

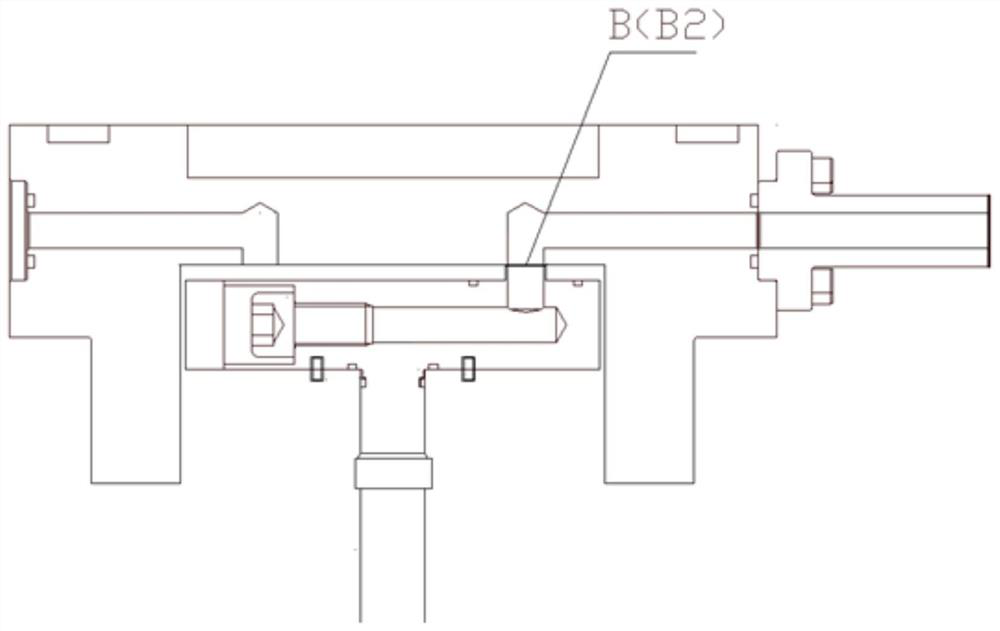

[0028] Such as Figure 1-5 As shown, a high-pressure multi-faceted turntable spray cleaning device with a compensation mechanism includes a motor 11, a reducer 2, an end cover 1, a main shaft 9, a compensation head 7, a turntable 3 and a plurality of nozzles 5, the output end of the motor 11 and the deceleration The high-speed shaft of the reducer 2 is rotationally connected. The end cover 1 is installed on the front side of the reducer 2 housing. One end of the main shaft 9 is connected to the end cover 1. The other end of the main shaft 9 is connected to the compensation head 7. One end of the compensation head 7 is in contact with the turntable 3. It is rotationally connected with the low-speed shaft of the reducer 2, and a plurality of nozzles 5 are respectively arranged on the side of the turntable 3.

[0029] Preferably, the main shaft 9 , the compensation head 7 and the turntable 3 are all provided with hollow passages inside.

[0030] Preferably, the rear end of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com