Pneumatic tire made of rubber composite material

A composite material, pneumatic tire technology, applied in tire measurement, tire parts, with multiple inflatable chambers, etc., can solve the problem of unusable tires, and achieve the effect of safe use, improved stability, and improved adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

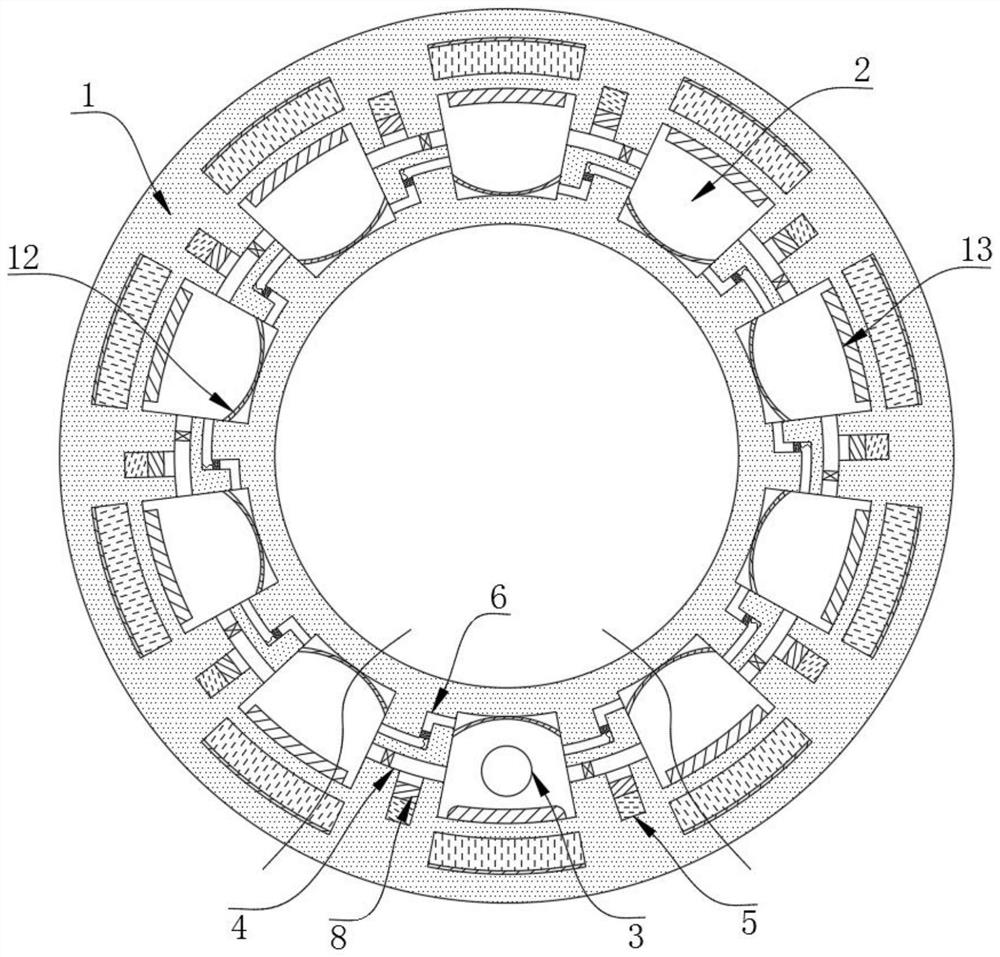

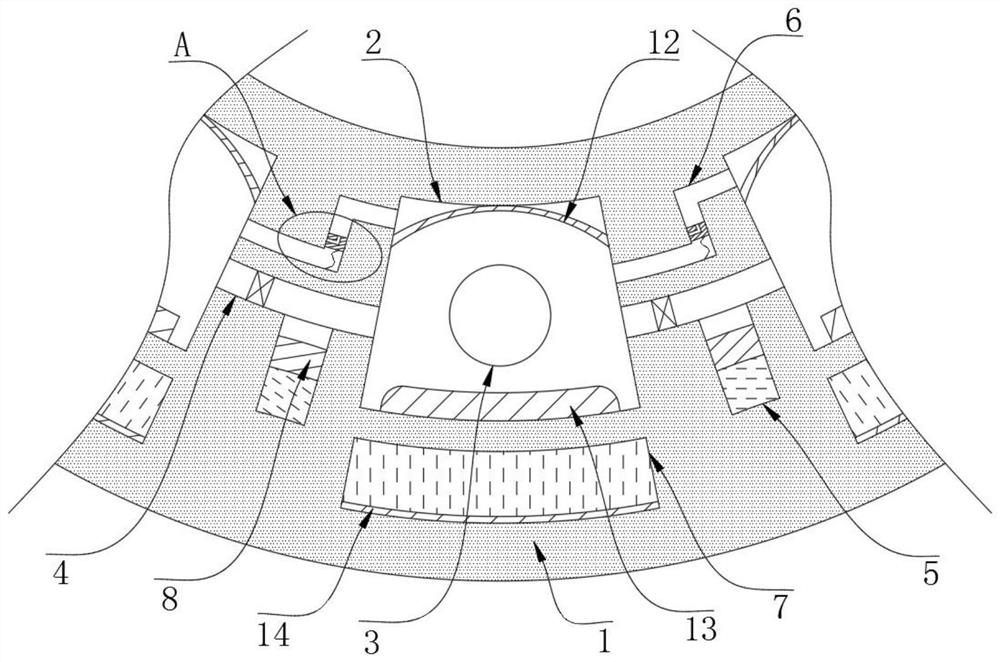

[0028] As an embodiment of the present invention, the explosion-proof mechanism includes a leak-repairing belt 12 fixed on the inner wall of the air chamber 2, and the side wall of the air chamber 2 is provided with a leak-repairing groove 6, and the inner wall of the leak-repairing groove 6 is connected by a spring 9 A communication block 10 is connected, and the side wall of the communication block 10 is provided with an air-filling hole 11;

[0029] When working, once the gas cavity 2 leaks, the other gas cavities 2 will distribute the gas inside the gas cavity 2 through the leakage repair groove 6, so that the leakage repair tape 12 will expand under the action of the distributed gas, and then the The leaked air cavity 2 is filled to ensure that the inside of the air cavity 2 is filled with gas, so that the local air pressure of the carcass 1 is not too low, causing the tire to run unstable, and the normal use of the carcass 1 is guaranteed.

[0030] As an embodiment of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com