A dual-motor power synthesis device for electric vehicle drive

A technology for power synthesis and electric vehicles, which is applied in the layout of electric power units, power units, and the cooling combination of power units, and can solve problems such as inconvenient control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

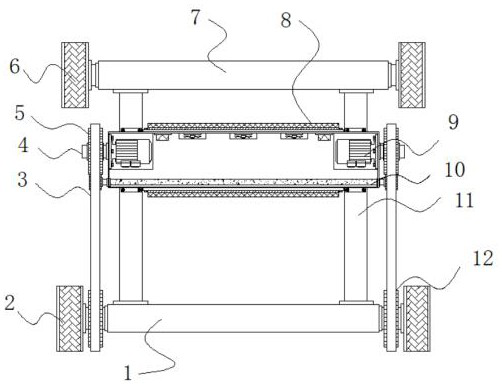

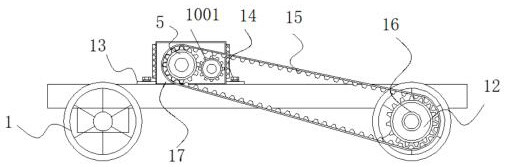

[0034] Example 1: See Figure 1-6 , a dual-motor power synthesis device for driving an electric vehicle, comprising a front pole 1 and a front wheel 2, two groups of front wheels 2 are fixedly connected to both sides of the front pole 1, and a rear pole 7 is arranged on the top of the front pole 1, Two groups of rear wheels 6 are fixedly connected to both sides of the rear bar 7, two groups of connecting rods 11 are fixedly connected between the front rod 1 and the rear rod 7, and one end of the connecting rod 11 is fixedly connected to a shell 17, the top of the shell 17 and the The bottom end is fixedly connected with a heat dissipation mechanism 8, and the bottom end inside the casing 17 is provided with an energy-saving structure 10, and four sets of fixing pieces 13 are arranged on both sides of the top and bottom of the casing 17, and two sets of fixing pieces 13 are fixedly connected on both sides of one end of the fixing piece 13. Bolts 14, wear-reducing structures 16 ...

Embodiment 2

[0036] Embodiment 2: Four sets of fixing pieces 13 are arranged on both sides of the top and bottom of the housing 17; the fixing bolts 14 penetrate one end of the fixing piece 13 and are fixedly connected with the connecting rod 11; specifically, as figure 1 and figure 2 As shown, the electric vehicle consumes a large amount of electric energy when in use, which increases the cost of use. When the vehicle does not need a large amount of electric energy to drive, it only needs to drive the variable speed motor 9 on one side, and the motor drives the first gear 5 to rotate. , the second gear 1001 that meshes with the first gear 5 also rotates, and then the second gear 1001 drives the gear on the other side to rotate to drive the vehicle to drive normally, which reduces energy consumption and saves a lot of electric energy. Reduced cost consumption.

Embodiment 3

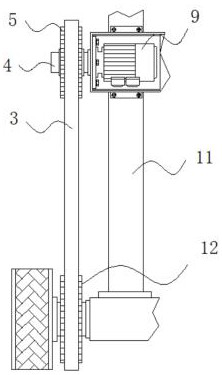

[0037] Embodiment 3: the heat dissipation mechanism 8 is made up of a heat dissipation gasket 801, a heat dissipation box 802, a heat dissipation hole 803, a blade 804 and a heat dissipation net plate 805, and the heat dissipation gasket 801 is fixedly connected to the top and bottom of the shell 17, and the heat dissipation gasket 801 The top is fixedly connected with a heat dissipation mesh plate 805, and the top inside the housing 17 is fixedly connected with three groups of heat dissipation boxes 802. The bottom of the heat dissipation box 802 is provided with a heat dissipation hole 803, and the inside of the heat dissipation box 802 is fixedly connected with a blade 804. The model of the blade 804 for DP200A;

[0038] The heat dissipation mesh plate 805 and the heat dissipation gasket 801 are on the same level; specifically, as figure 1 and Figure 4 As shown, the device will generate a large amount of heat energy under high-intensity use. The temperature sensor install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com