Food sealing bag packaging control method executed based on deoxidizer synchronous delivery mechanism

一种机构执行、控制方法的技术,应用在包装、运输包装、运输和包装等方向,能够解决工作效率低、易受外部污染、包装物料不平整封口等问题,达到提高工作效率、减小移动距离、方便下压封口的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

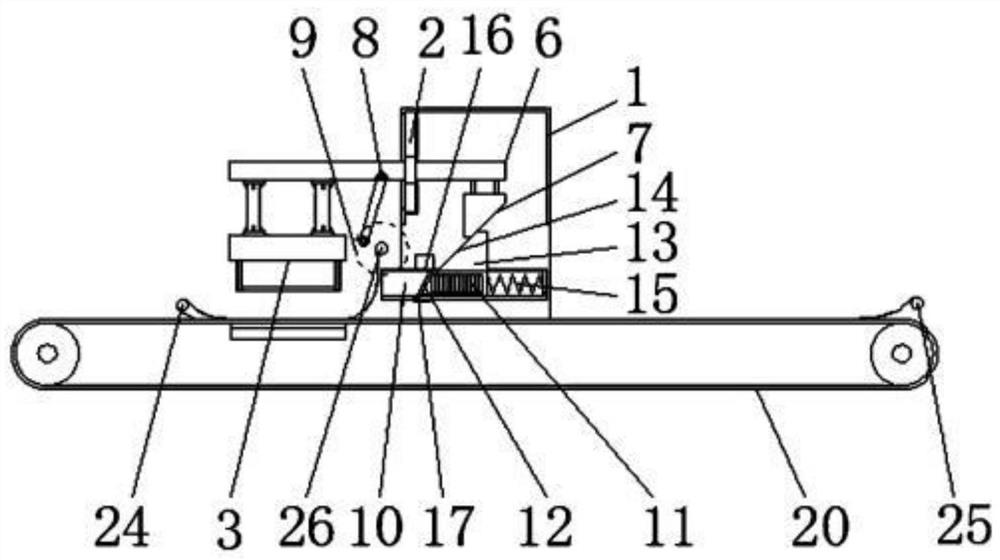

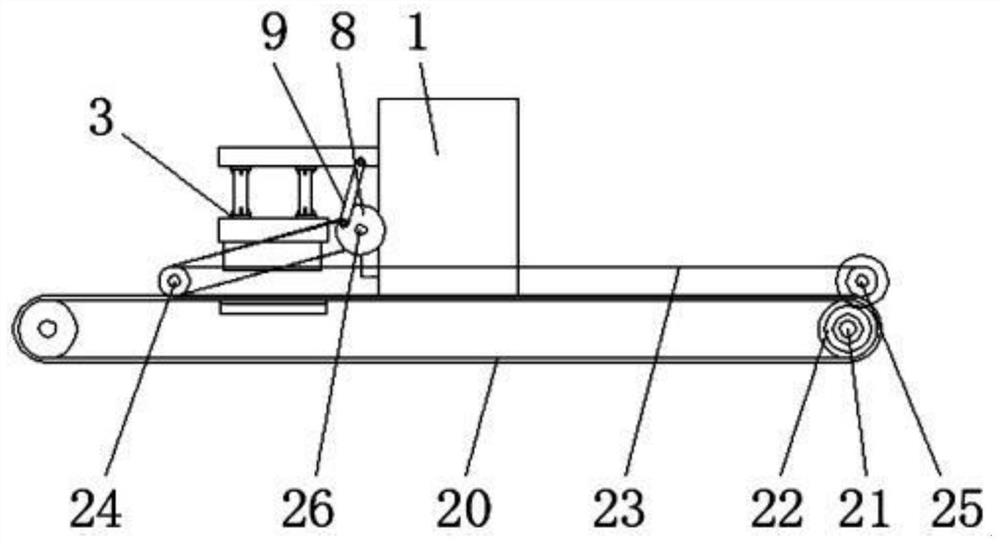

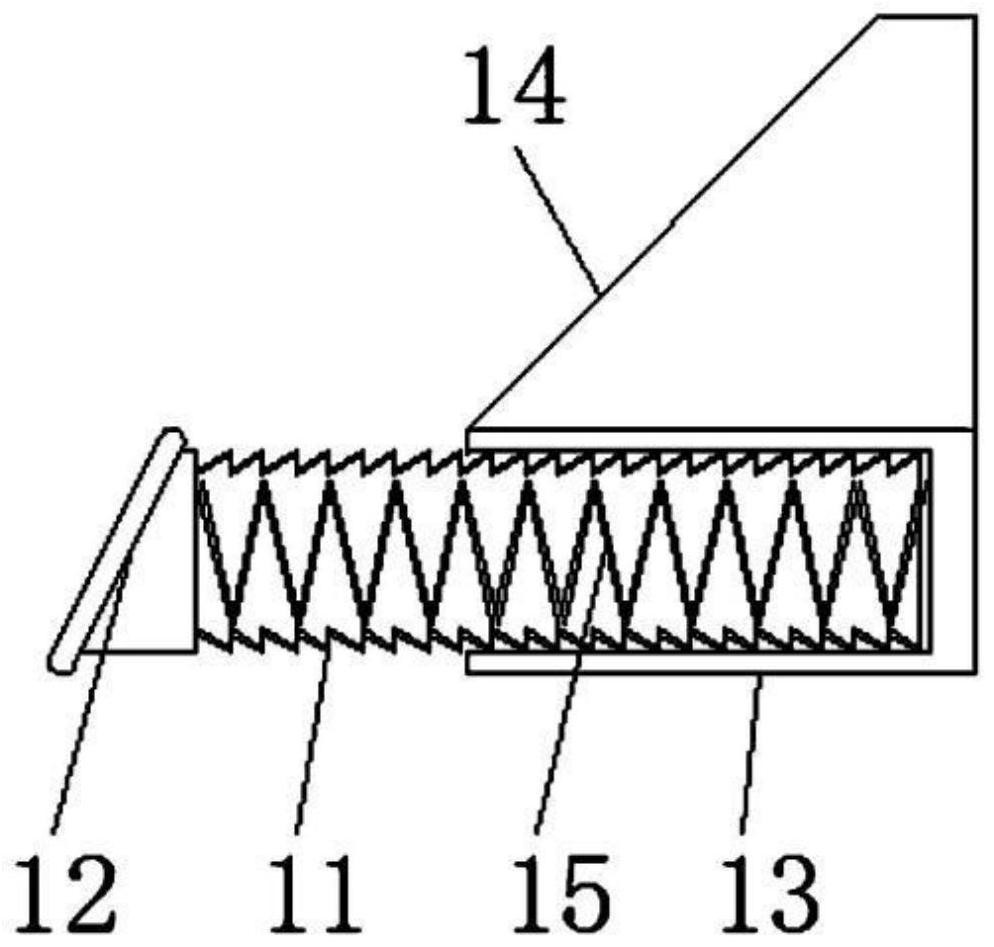

[0032] see Figure 1-10 The present invention provides a technical solution: a food sealing bag packaging control method based on a deoxidizer synchronous delivery mechanism, the deoxidizer synchronous delivery mechanism includes a mounting frame 1, a movable guide rail 2, a movable mounting frame 3, Cross cutting knife 4, heat sealing strip 5, synchronous movable seat 6, extruding slope 7, connecting transmission rod 8, side driving wheel 9, movable channel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com