Mixing machine for jade fiber blending

A technology of jade fiber and mixing machine, which is applied in fiber processing, textile and papermaking, and filament forming treatment, etc. It can solve the problems of the influence of jade fiber blending ratio, and achieve the effect of easy slip flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] as attached figure 1 to attach Image 6 Shown:

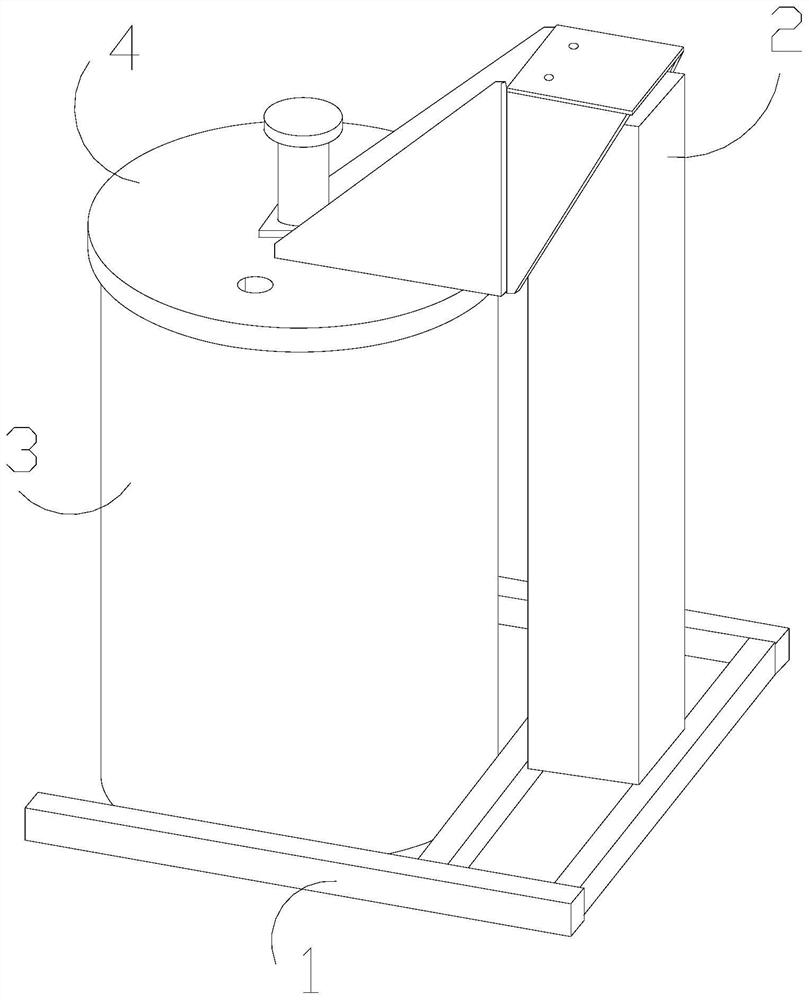

[0030] The present invention provides a jade fiber blending mixer, the structure of which is provided with a stable base 1, a console 2, a mixer 3, and a top cover 4, the bottom of the console 2 is welded to the upper end of one side of the stable base 1, and the The mixer 3 is located inside the stable base 1 , the top cover 4 is engaged and connected to the top of the mixer 3 , and the console 2 is located at the outer end of the mixer 3 .

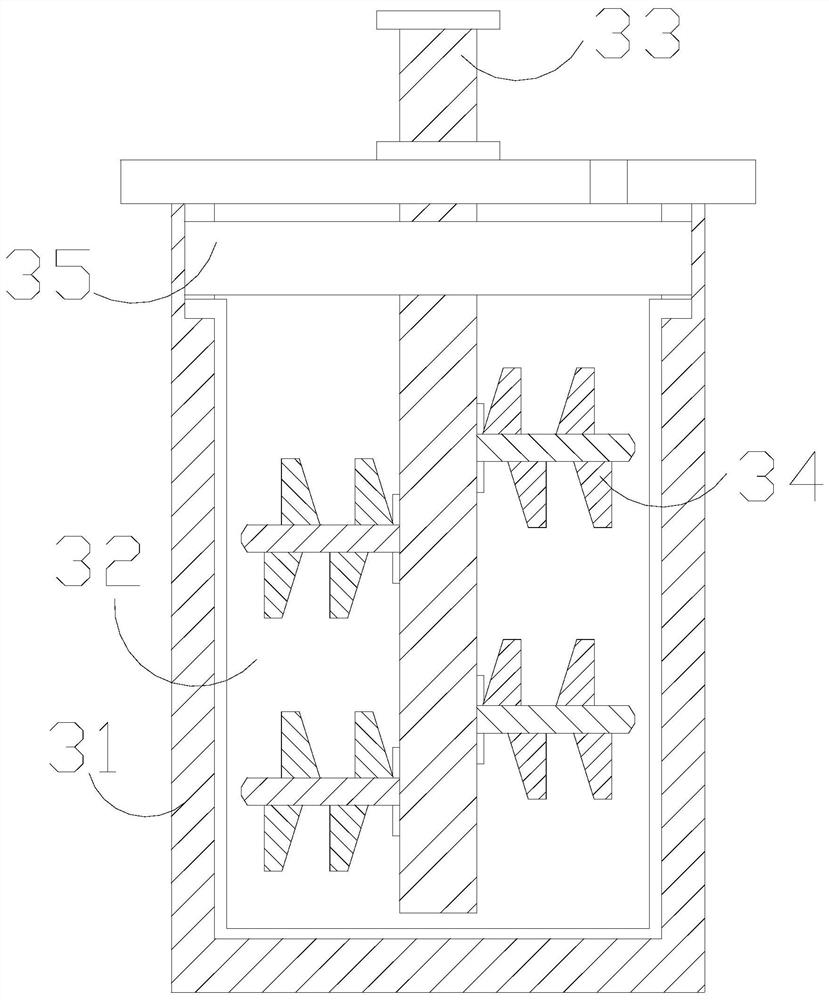

[0031] The mixer 3 is provided with an outer container 31, an inner container 32, a drive shaft 33, a stirring paddle 34, and a water guide plate 35. The inner container 32 is connected to the inner side of the outer container 31 with clearance fit, and the drive shaft 33 runs through Moving inside the inner tank 32, the stirring paddle 34 is movably connected and movably matched with the drive shaft 33. The water guide plate 35 is located at the inner upper end of the inner tank ...

Embodiment 2

[0037] as attached Figure 7 to attach Figure 8 Shown:

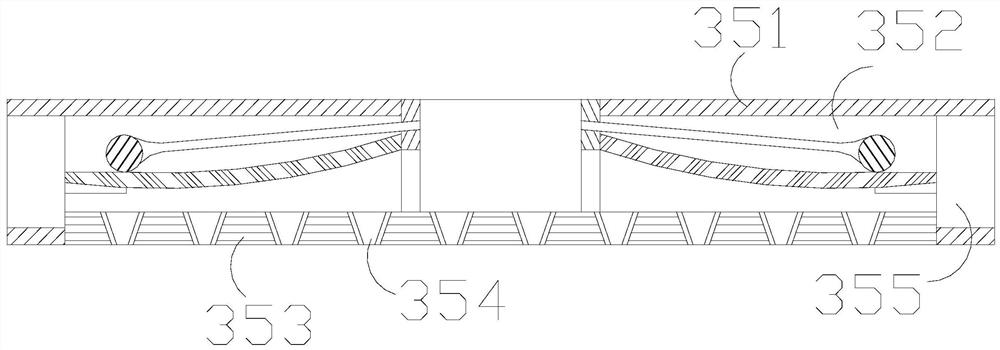

[0038] Wherein, the bending guide plate 242 is provided with a plate frame 421, a telescopic port 422, a cavity 423, a water-absorbing block 424, an extruding rod 425, and a protrusion 426, and the telescopic port 422 and the plate frame 421 are an integrated structure and set At the bottom end of the plate frame 421, the hollow cavity 423 is located inside the plate frame 421, the water-absorbing block 424 is embedded and connected in the hollow cavity 423, and the water-absorbing block 424 is connected with the telescopic port 422 with a clearance fit and is movable. The extruding rod 425 is slidably connected to the upper and lower side walls of the cavity 423, the extruding rod 425 is located between the water-absorbing blocks 424 and is movably fitted, and the protrusion 426 is embedded and connected to the bottom rear end of the plate frame 421 position, the telescopic port 422 is a rubber strip edge material wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com