Wetting device for compact spinning yarns

A technology for wetting device and spinning yarn, which is applied in the directions of processing textile material equipment configuration, textile material container processing, spraying/jetting textile material processing, etc. The effect of convenience, saving water resources and expanding operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

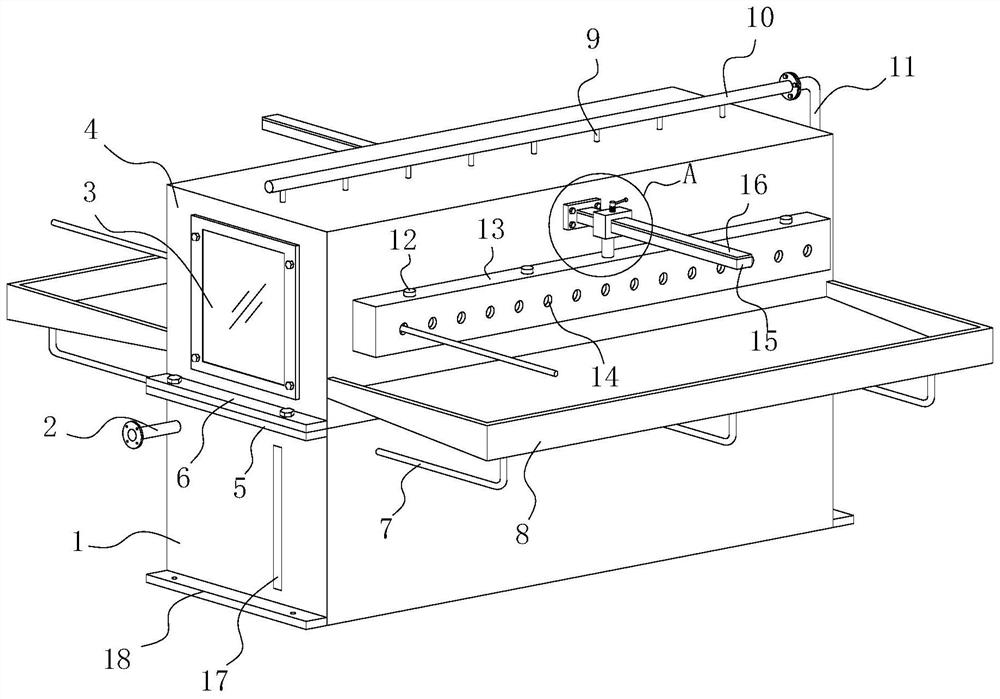

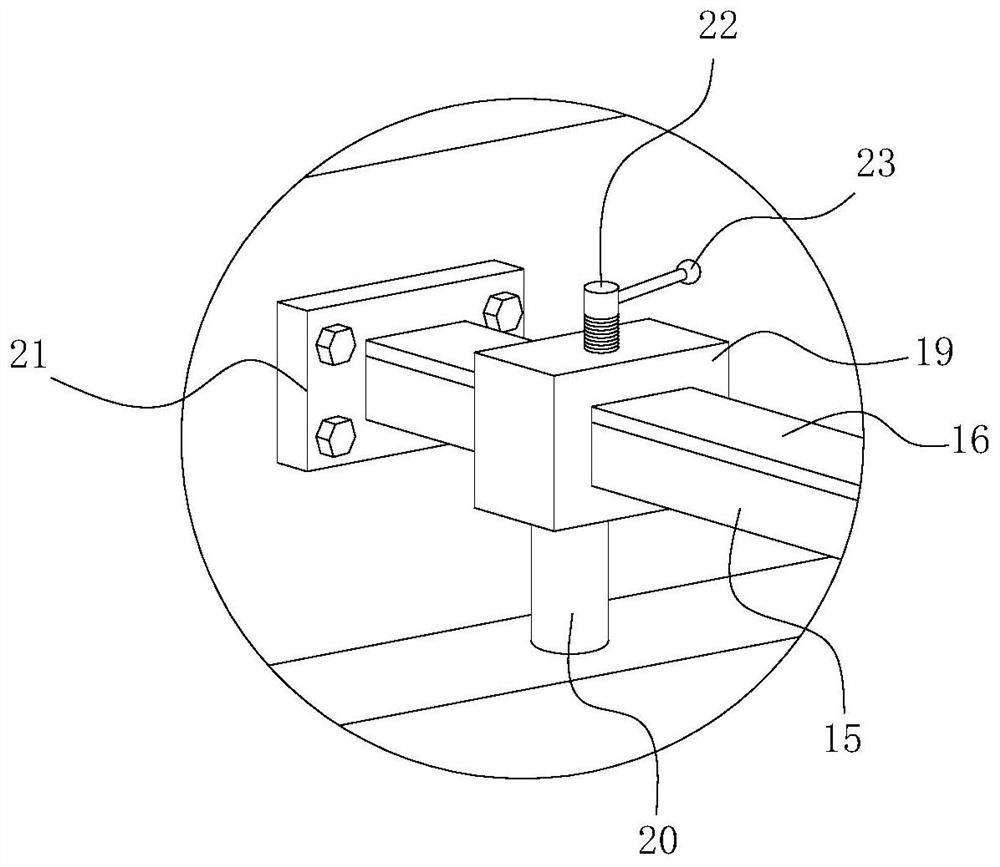

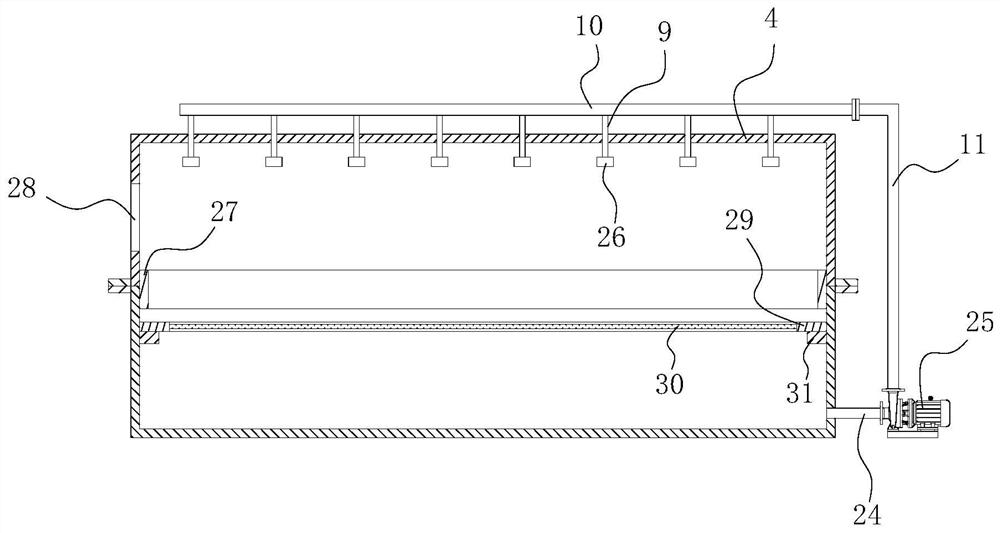

[0037] Specific implementation method: use bolts to fix the bottom plate 18 at the desired position, complete the fixing of the position of the water storage tank 1, and use bolts to connect the first connecting side 5 and the second connecting side 6 to realize the fixing of the wet cover 4 and the water storage tank 1 Connect, at this time, a part of the rectangular frame 27 extends into the water storage tank 1 and fits with the inner wall of the water storage tank 1, so that the water will overflow from the intersection of the wet cover 4 and the water storage tank 1, and the yarn will be threaded through the strip opening 32. into the wet cover 4, and use external winding equipment to drive the yarn to move, connect the circuit of the water pump 25, and the water pump 25 works to transport the moisture in the water storage tank 1 to the water distribution pipe 10 through the connecting pipe 24 and the water delivery pipe 11, The moisture in the water distribution pipe 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com