A food packaging waxing base paper processing system and process thereof

A technology for food packaging and paper processing, applied in textiles and papermaking, pulp raw material addition process, papermaking, etc., can solve the problems of lowering the quality of base paper, affecting the efficiency of waxing, and breaking the base paper, so as to improve the quality of waxing and improve the wax liquid. Quality, blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

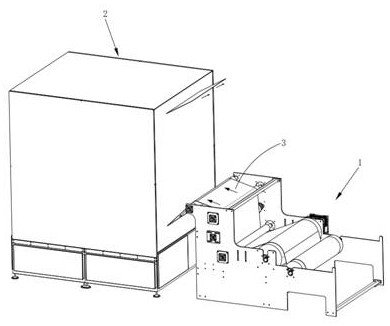

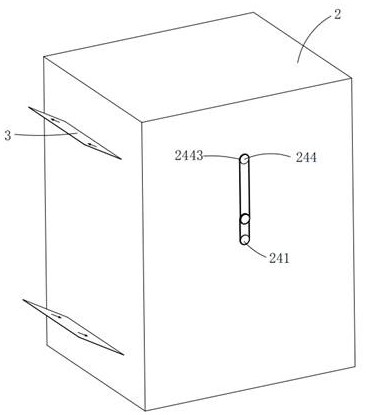

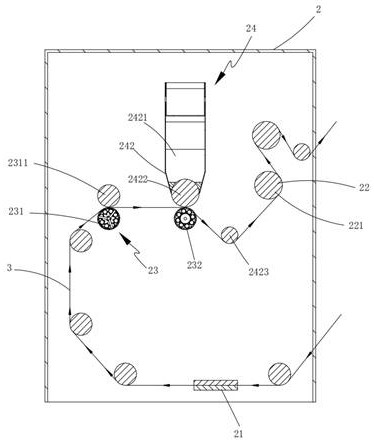

[0045] Such as Figure 1 to Figure 3 shown. A waxing base paper processing system for food packaging, comprising an unwinding device 1 and a waxing box 2 arranged in sequence, a preheating assembly 21 is arranged at the inlet of the waxing box 2, and a cooling assembly is arranged at the outlet 22. It is characterized in that, the waxing box 2 is also provided with:

[0046] Stretching assembly 23, said stretching assembly 23 is located between comprising said preheating assembly 21 and said cooling assembly 22, and it comprises the rotating roller a231 that is arranged in sequence along the base paper conveying path and is used for forward conveying base paper and rotating roller a231. The roller b232, correspondingly fixedly installed on the rotating roller a231 and the mounting seat 233 at both ends of the rotating roller b232, several groups of friction roller mechanisms 234 installed on the mounting seat 233 in a circular array, correspondingly fixedly installed on the r...

Embodiment 2

[0071] Such as Figure 12 As shown, a kind of food packaging wax base paper processing technology of the second embodiment of the present invention is described with reference to the first embodiment, comprising the following steps:

[0072] Step 1: base paper unwinding, unwinding equipment 1 unwinds the base paper to be waxed;

[0073] Step 2: Preheating the base paper. After Step 1, the base paper is transported to the preheating assembly 21 for preheating treatment, and the preheated base paper is transported between the rotating roller a231 and the rotating roller b232;

[0074]Step 3: Stretching the base paper. After step 2, the turning roller a231 and the turning roller b232 are rotated to transport the base paper forward. At the same time, under the action of the driving component a235 and the driving component b236, they are correspondingly arranged on the turning roller a231 The friction roller mechanisms 234 on both sides are reversed and produce oblique rearward te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com