Finned tube type heat collecting plate, preparation method thereof, heat collector, and water heater

A technology of heat collecting plate and heat collector, which is applied in the field of heat collecting plate to achieve the effect of improving heat conversion efficiency, high heat conversion efficiency and avoiding shading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

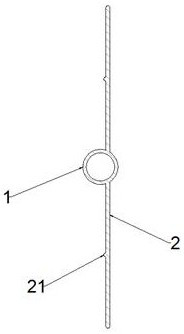

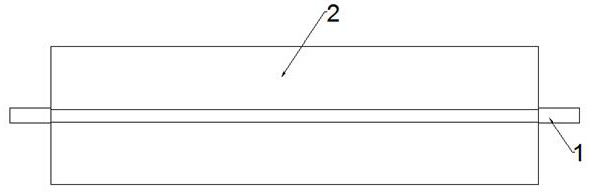

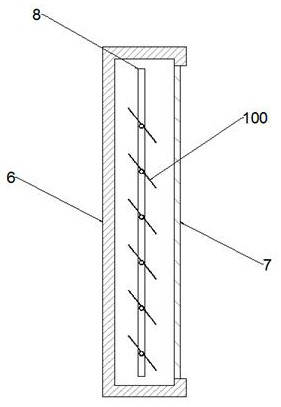

[0029] refer to figure 1 and figure 2 As shown, a finned tube type heat collecting plate includes a refrigerant pipe 1 and a heat absorbing plate 2. The backlight surface of the heat absorbing plate 2 is integrally formed with a refrigerant pipe 1 along the axial direction, wherein the refrigerant pipe 1 and the heat absorbing plate 2 They are all made of metal aluminum. Compared with the traditional way of welding with copper tubes, the cost of this solution is lower.

[0030] In one aspect, both ends of the refrigerant pipe 1 protrude from the end surface of the heat absorbing plate 2 at the end, and the protruding section is used to connect with the header 8 during installation, and the length of the protruding section is usually 3-5 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com