Fault detection and reconstruction method for liquid level system of water-cooled cabinet

A system failure, water-cooling technology, applied in general control systems, control/regulation systems, liquid/fluid solids measurement, etc., can solve problems such as difficult implementation of engineering applications, and achieve the effect of facilitating writing and improving fault tolerance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

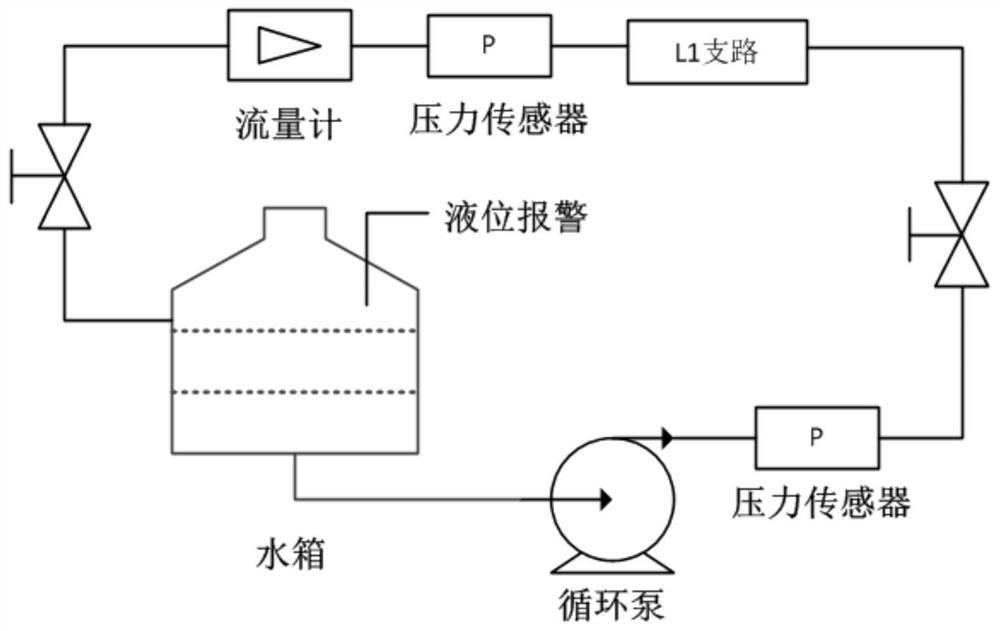

[0014] The method of the present invention will be further illustrated below in conjunction with the accompanying drawings and embodiments.

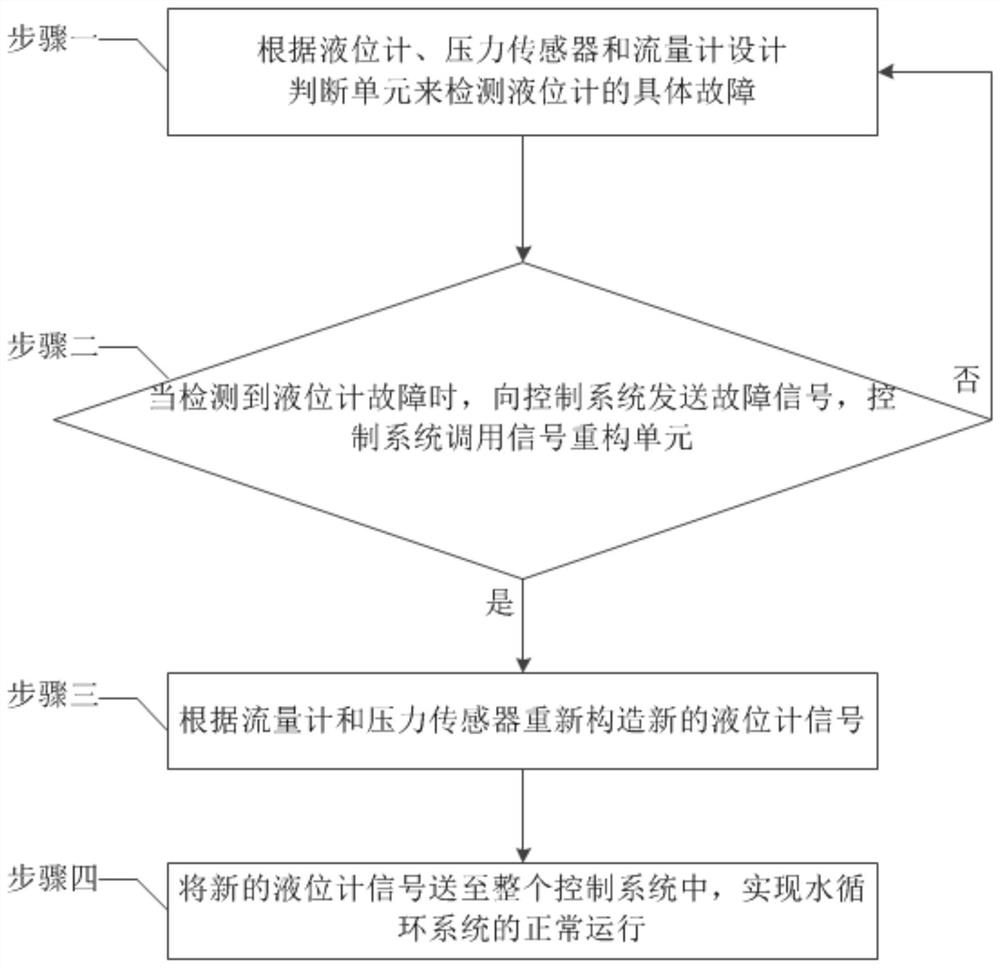

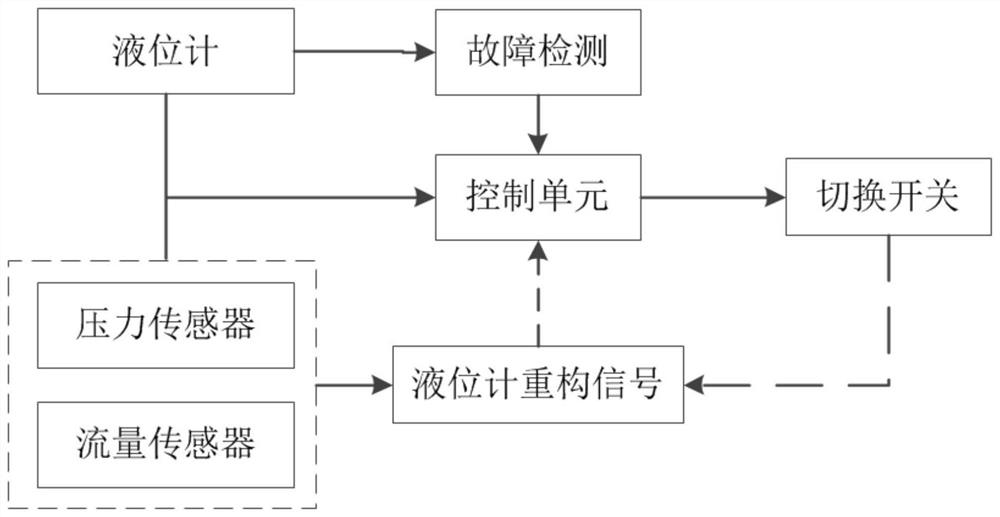

[0015] The present invention proposes a method for fault detection and reconstruction of the liquid level system of a water-cooled cabinet, and the embodiment includes the following steps:

[0016] Step 1: According to the feedback signal h of the liquid level gauge, the pressure signal p, and the flow signal Q, the three signals comprehensively judge whether the liquid level gauge is faulty;

[0017] Step 2: When it is judged that the liquid level gauge is faulty, the control unit of the water-cooled cabinet receives a fault signal, and the system switches the signal of the liquid level gauge; if there is no fault, return to step 1 for real-time detection;

[0018] Step 3: Reconstruct the liquid level gauge signal according to the pressure signal in the system and the flow signal of the water inlet and outlet, and call it by the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com