A wind tunnel diaphragm clamping device

A clamping device and diaphragm technology, which is used in measuring devices, testing of machine/structural components, instruments, etc., can solve problems such as difficult on-site cleaning, poor clamping of diaphragms, and difficulty in replacing sealing rings, so as to improve reliability. and safety, reducing processing and manufacturing costs, and convenient use and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

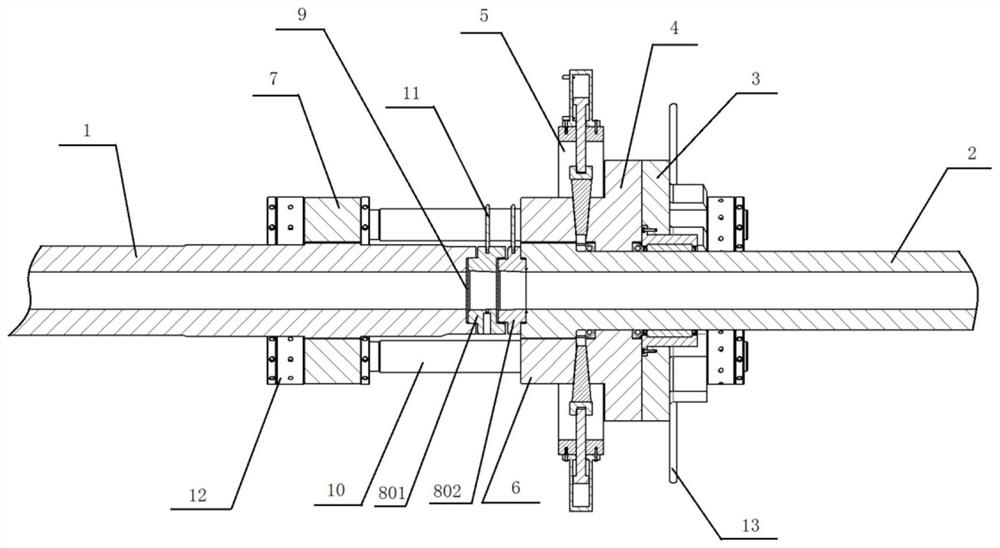

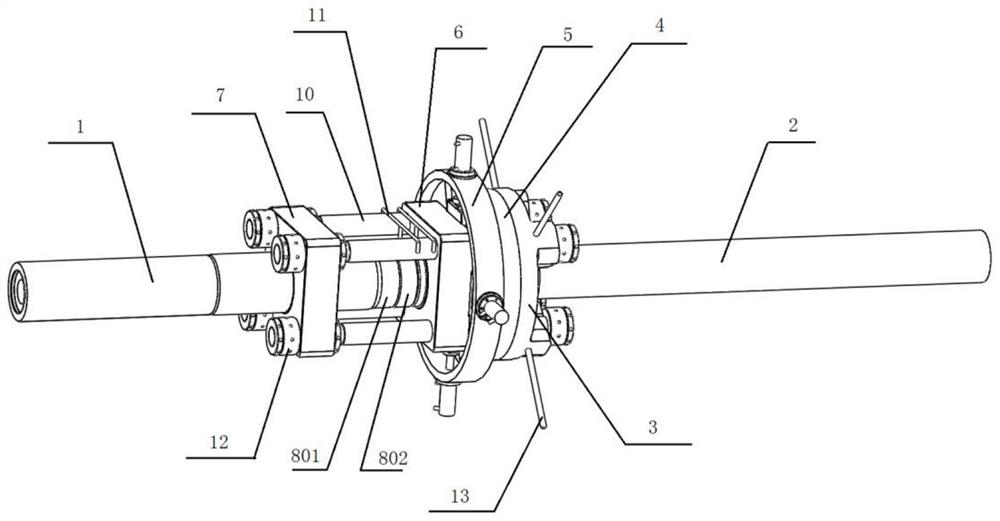

[0049] After a large-scale shock wave wind tunnel blowing test is completed, the broken diaphragm 9 needs to be replaced. At this time, the diaphragm clamping device of the wind tunnel is in the figure 2 Clamped state shown.

[0050] The specific replacement process is as follows:

[0051] 1. The wedge 15 is pulled out by the piston of the hydraulic cylinder 14, and the locked wedge 15 is released;

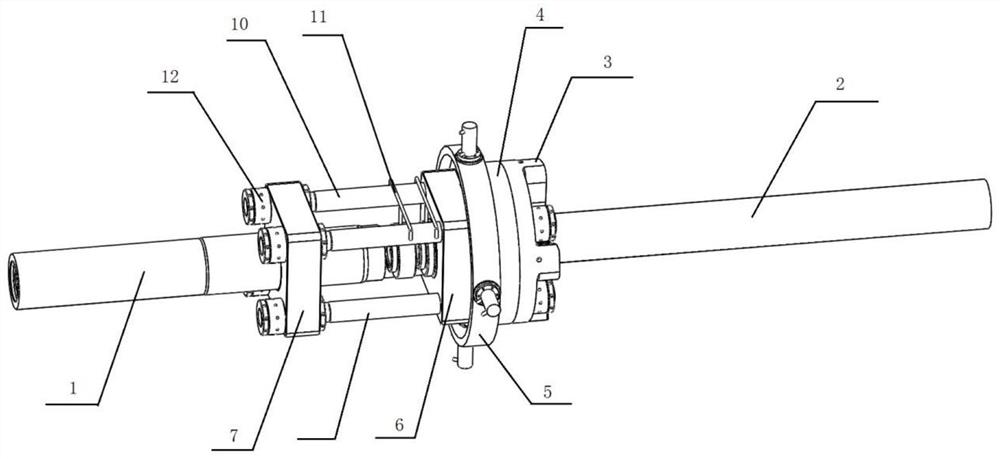

[0052] 2. Move the crowbar 13, turn the pressure block 3, so that the nut 12 on the pull rod 10 is rotated from the position of the boss 20 to such as image 3 The position of the groove 21 is shown;

[0053] 3. Use the traction system of the large-scale shock tunnel to pull the upstream pipe section 1 to the upstream direction, and then take out the broken diaphragm 9 and replace it with a new diaphragm 9;

[0054] 4. Use the wind tunnel diaphragm clamping device of the present invention to clamp the diaphragm 9 in reverse steps for the next test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com