Test fixture, resistance test device and method, and conductivity test method

A test fixture and resistance test technology, applied in the direction of measuring resistance/reactance/impedance, measuring device, measuring device casing, etc., can solve the problems of conductivity error, affecting the judgment of finished products, and the length of the wire cannot be determined, so as to ensure convenience performance, improve accuracy, and improve convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

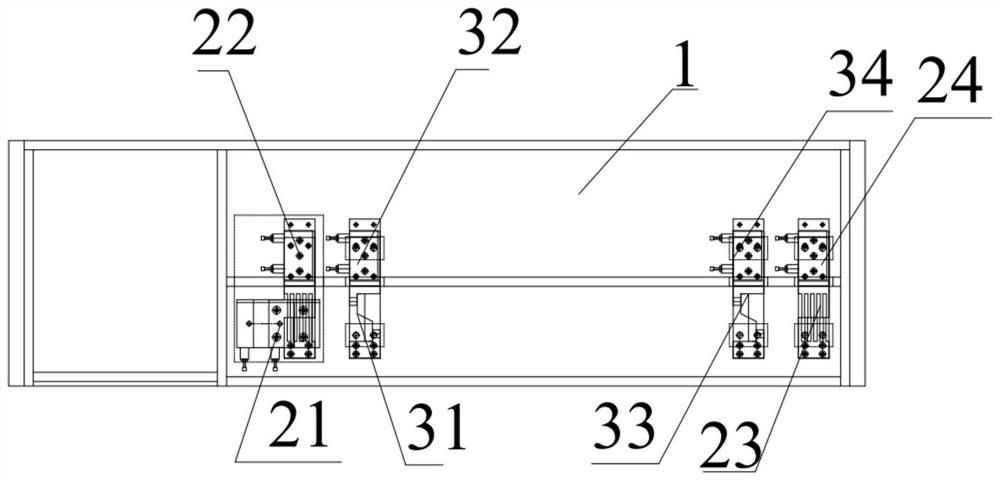

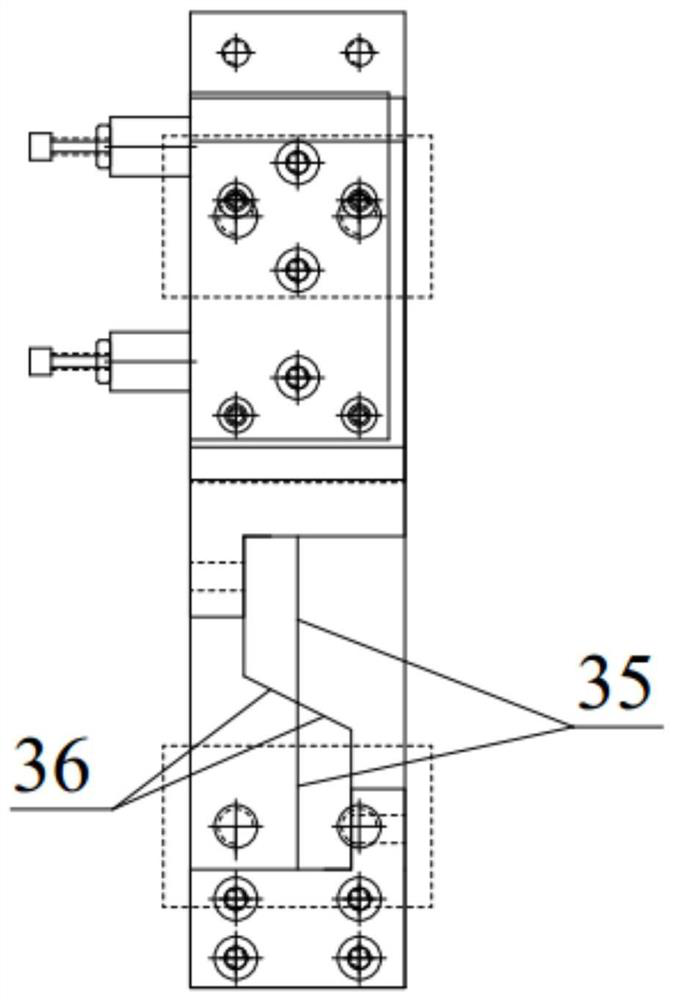

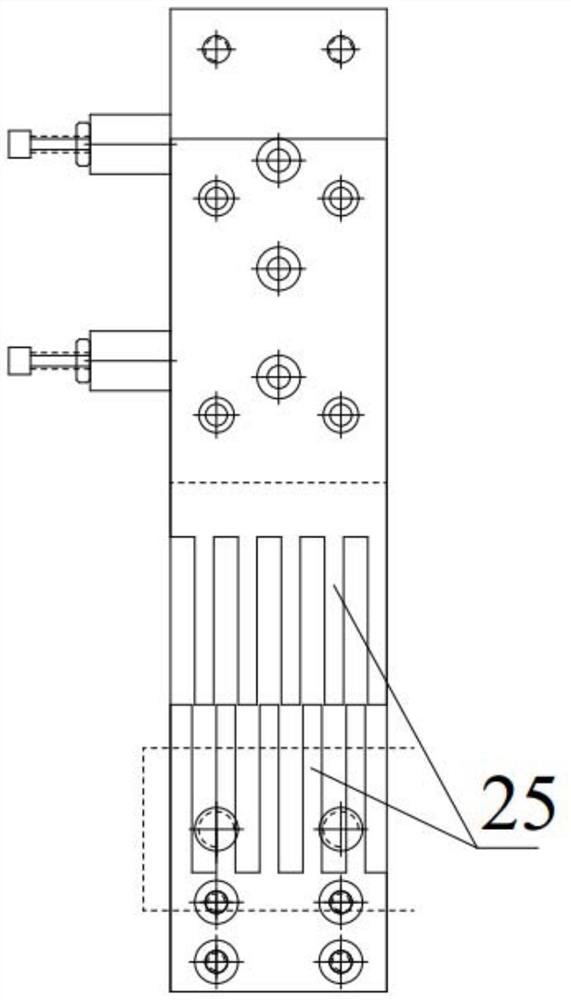

[0059] This embodiment provides a test fixture, such as Figure 1 to Figure 3 As shown, it includes: a substrate 1, a pre-clamping mechanism, a clamping mechanism and a driving mechanism. Wherein, both the pre-clamping mechanism and the clamping mechanism are installed on the base plate 1, and the driving mechanism drives the movement of the clamping mechanism and the pre-clamping mechanism. The pre-clamping mechanism includes two pre-clamping parts, and the pre-clamping parts form a pre-clamping space for clamping the test piece; the clamping mechanism includes a pair of measuring clamping parts, and any measuring clamping part has a The clamping space of the test piece; a pair of measuring clamps encloses the measurement space of the test piece, and the two pre-clamping pieces are placed on both sides of the measurement space.

[0060] In other optional embodiments, the pre-clamps can be set as two pairs, three pairs or more. Of course, it needs to be ensured that any pre-c...

Embodiment 2

[0077] This embodiment provides a resistance testing device, including: a measuring mechanism and the test fixture in Embodiment 1. Wherein, the measuring mechanism is used for testing the resistance of the test piece arranged in the measurement space along the extending direction of the length of the test piece.

[0078] Specifically, the object to be tested in this embodiment is a copper-clad steel wire as an example, and the measuring mechanism includes a micro-ohmmeter for measuring resistance.

Embodiment 3

[0080] This embodiment provides a resistance testing method, comprising the following steps:

[0081] S1: Installation: at least two pre-clamps are installed on the outside of the measurement space formed by the two measuring clamps;

[0082] S11: Install the first measuring fixture and the second measuring fixture on the substrate 1

[0083] S12: Install the first pre-clamp on the left side of the first measurement clamp, install the second pre-clamp on the right side of the second measurement clamp, and ensure that the first pre-clamp teeth 21 and the third pre-clamp The points where the tooth tips of the tooth 23 , the first measuring tooth 31 , and the third measuring tooth 33 are located or the surfaces where the tooth tips are located are coplanarly arranged.

[0084] S2: Pre-clamping: the pre-clamping part clamps the part to be tested;

[0085]S21: Place the test piece on the first pre-clamping tooth 21 and the second pre-clamping tooth 22, the first measuring tooth 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com