MT insertion core structure

A ferrule and channel technology, which is applied in light guides, optics, instruments, etc., can solve problems such as uneven adhesive layer thickness, weakened strength, and easy breakage, so as to improve product reliability, increase module internal space, and enhance optical fiber protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of the present invention are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

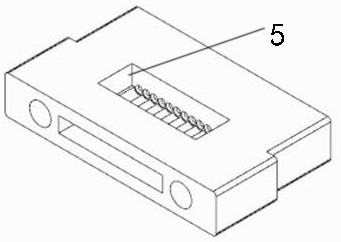

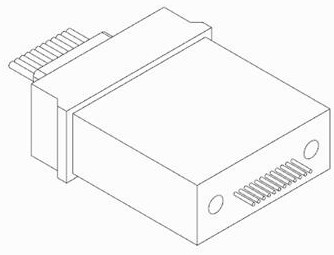

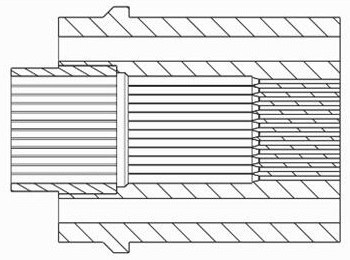

[0031] Figure 5-7 Shown is the MT ferrule structure designed by the present invention, including the ferrule body, the front end of the ferrule body is provided with a fiber cladding channel 1, the rear end of the ferrule body is provided with a fiber coating channel 2, and the fiber cladding channel 1 is used to fix the fiber cladding, the fiber coating channel 2 is used to fix the fiber coating, the transition between the fiber cladding channel 1 and the fiber coating channel 2 is guided, the ferrule body has two There are front and rear guide holes 3 at the end, the top and bottom of the ferrule body are closed, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com