Domain self-adaptive equipment operation inspection system and method

A domain-adaptive, equipment-based technology, applied in the field of domain-adaptive equipment inspection systems, can solve problems such as infeasibility, poor model performance, and expensive training samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

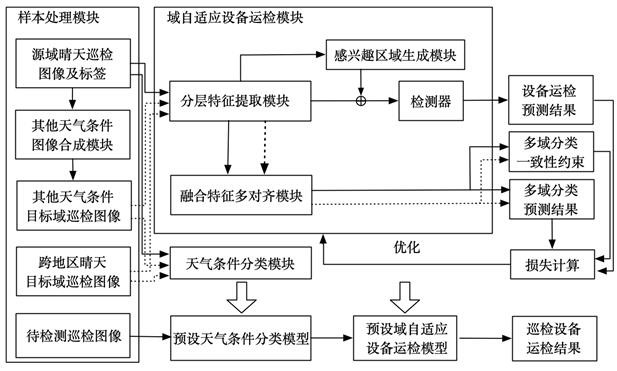

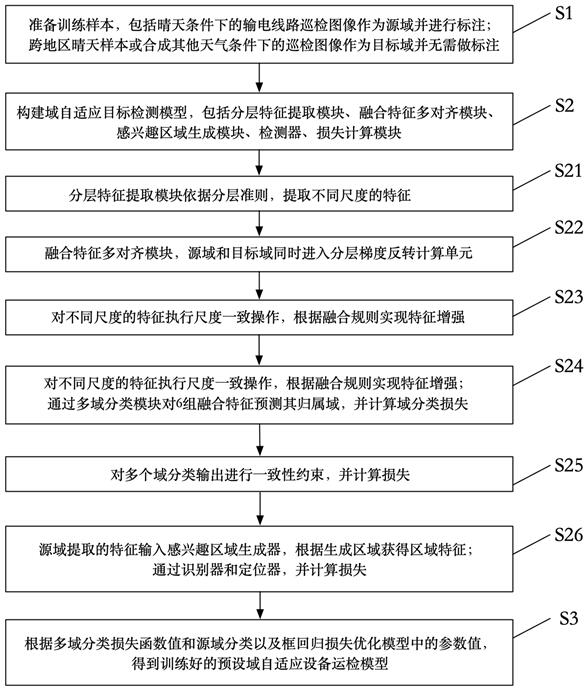

[0056] In this embodiment, a domain adaptive equipment inspection system, such as figure 1 As shown, it includes an image acquisition processing module, a weather condition classification module, and a domain adaptive equipment inspection module;

[0057] The domain adaptive equipment inspection module is used to construct and preset a domain adaptive equipment inspection model. The domain adaptive equipment inspection model includes a layered feature extraction module, a fusion feature multi-alignment module, a region of interest generation module, a detection device and loss calculation module;

[0058] The image acquisition and processing module is used to acquire the transmission line equipment inspection image and preprocess the inspection image, and send the preprocessed inspection image to the weather condition classification module and the domain adaptive feature extraction module;

[0059]The weather condition classification module is used to construct and preset a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com