Online fault diagnosis method for rolling bearing under variable load based on transfer learning

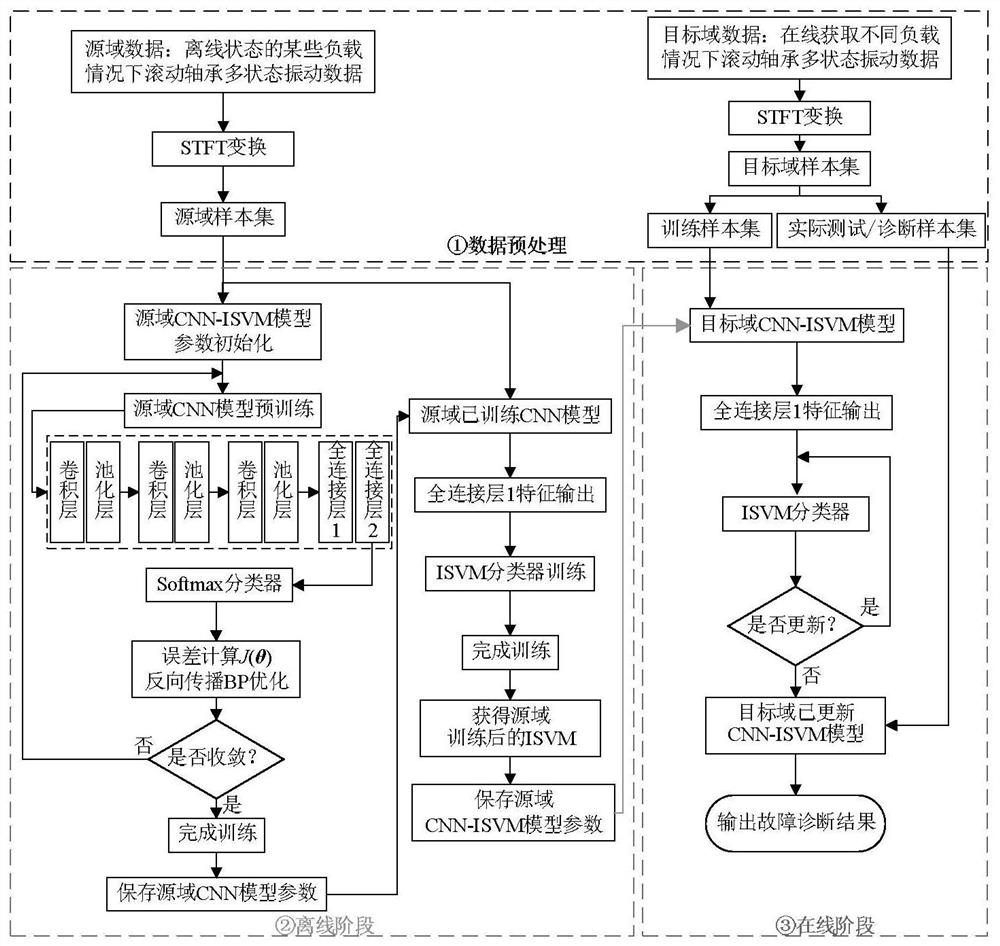

A rolling bearing and fault diagnosis technology, which is applied in the field of online fault diagnosis of rolling bearings under variable loads of transfer learning, can solve the problems such as the inability to effectively guarantee the modeling efficiency and accuracy of online fault diagnosis of rolling bearings under variable loads, so as to solve the problems of online fault diagnosis, The effect of reducing distribution differences and high modeling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0087] In order to verify the validity and accuracy of the method of the present invention, the bearing data set of Case Western Reserve University in the United States is used for experimental verification [23] . Bearing test bench such as Figure 4 As shown, these data are collected by the acceleration sensor under 4 kinds of load conditions, and the sampling frequency is 12kHz.

[0088] Load types include 0hp, 1hp, 2hp and 3hp, and the motor speed varies between 1730rpm and 1797rpm depending on the load. Under each load, there are three types of fault damage levels: normal state (N) and inner ring fault (IR), outer ring fault (OR) and rolling element fault (B). The damage diameters are 0.1778mm, 0.3556mm, and 0.5334 mm respectively. mm, there is no damage to the rolling bearing under normal conditions, so there is no fault location and damage degree. Classify the normal state of rolling bearings, inner ring, outer ring, rolling element faults and 10 states of different f...

specific Embodiment 2

[0117] In order to better verify the efficiency of the method of the present invention, the time consumption and accuracy of the three methods were compared. The setting of the online data set is consistent with Table 5, and the experimental results are shown in Table 7.

[0118] Table 7 Comparison of time consumption and accuracy of the three methods

[0119]

[0120] In the experiment, method 1 and method 2 adopt the offline training method, that is, retrain the model each time to process the new online data; method 3 is the online training method, and only need to update the model for the newly added online data. Method 1 is to combine CNN and Softmax to carry out backpropagation optimization training CNN model; method 2 is to carry out feature extraction to the fault data with the CNN model trained in method 1, and then input SVM to carry out fault classification; method 3 is the CNN proposed by the present invention -ISVM rolling bearing multi-state identification meth...

specific Embodiment 3

[0123] In order to further prove that the method of the present invention has obvious advantages in online fault diagnosis of rolling bearings under variable loads, ISVM, OS-ELM [28] And the online learning method proposed in the literature [29] for comparative experimental research. Among them, the ISVM and OS-ELM methods adopt the feature extraction method of literature [30] to extract 10 kinds of time-domain features and 4 kinds of frequency-domain features, and then input the extracted features into the diagnosis algorithm to complete the fault diagnosis. During the experiment, the same source domain and target domain datasets were used, the time comparison results are shown in Table 8, and the accuracy comparison results are shown in Table 8. Figure 11 shown.

[0124] Table 8 Time comparison with other methods

[0125]

[0126] It can be seen from Table 8 that the average online learning time of the method proposed in the present invention is 16.97s, which is about ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com