Winding direction alternate continuous coil winding device and method

A winding device and winding direction technology, which is applied in coil manufacturing, electromechanical devices, and motor generator manufacturing, can solve the problems of difficult control of wire length, low winding efficiency, and manual counting, so as to improve reliability and practicality. performance, improved winding efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

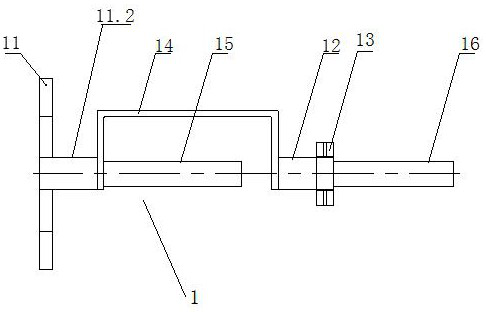

[0046] Combine below Figure 1 to Figure 8 The embodiments of the present invention will be described in detail.

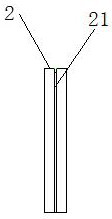

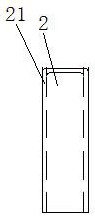

[0047] The winding direction alternating continuous coil winding device is characterized in that: it includes a winding device 1 for winding continuous double-cake coils and changing the winding direction of the double-cake coils alternately; The wire is bent into a U-shaped connecting wire bending plate 2. The winding device 1 is detachably connected to the faceplate of the winding machine, and the coil is wound with the rotation of the faceplate of the winding machine, and the winding direction is alternately changed, and the phase is changed. The connecting lines between adjacent double-cake coils are bent into a U-shape with a connecting wire bending plate 2 to form a continuous coil in which left-wound double-cake coils and right-wound double-cake coils alternate.

[0048]In the above-mentioned alternate winding continuous coil winding device, the winding de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com