Auxiliary paper feeding device of scanner

A scanner and paper feeding technology, applied in image communication, electrical components, etc., can solve the problems of affecting the scanning progress, the whole stack of paper collapses and leaves the paper feeding platform, and the whole stack of paper easily collapses and leaves the paper feeding platform, etc., to prevent collapse. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020]The embodiments of the present invention will be further described below in conjunction with the drawings.

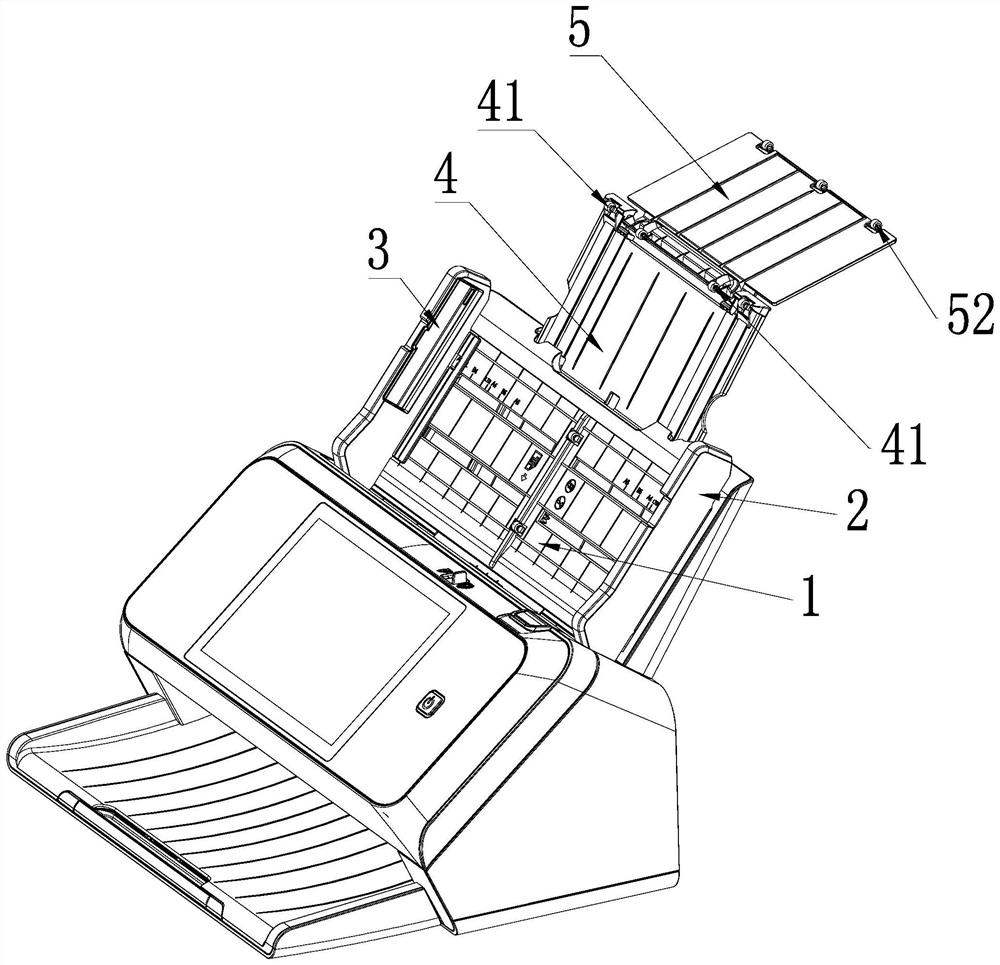

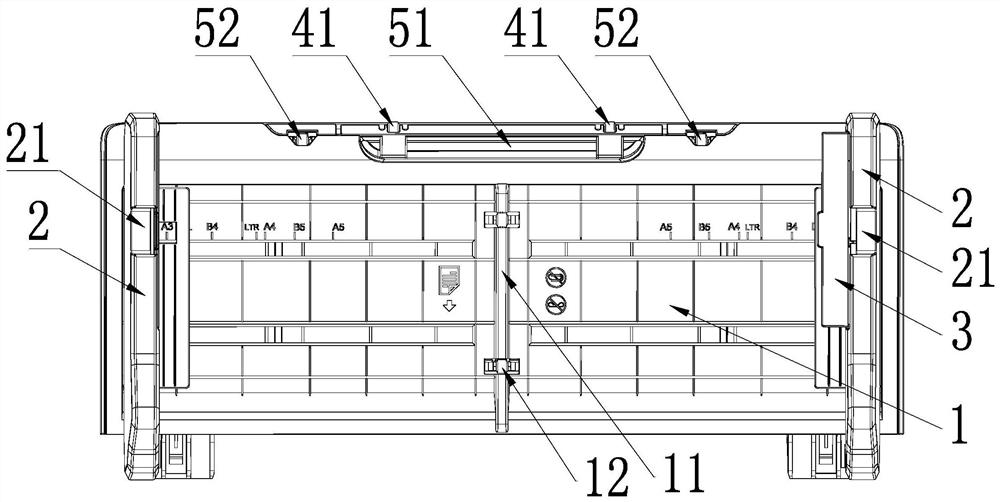

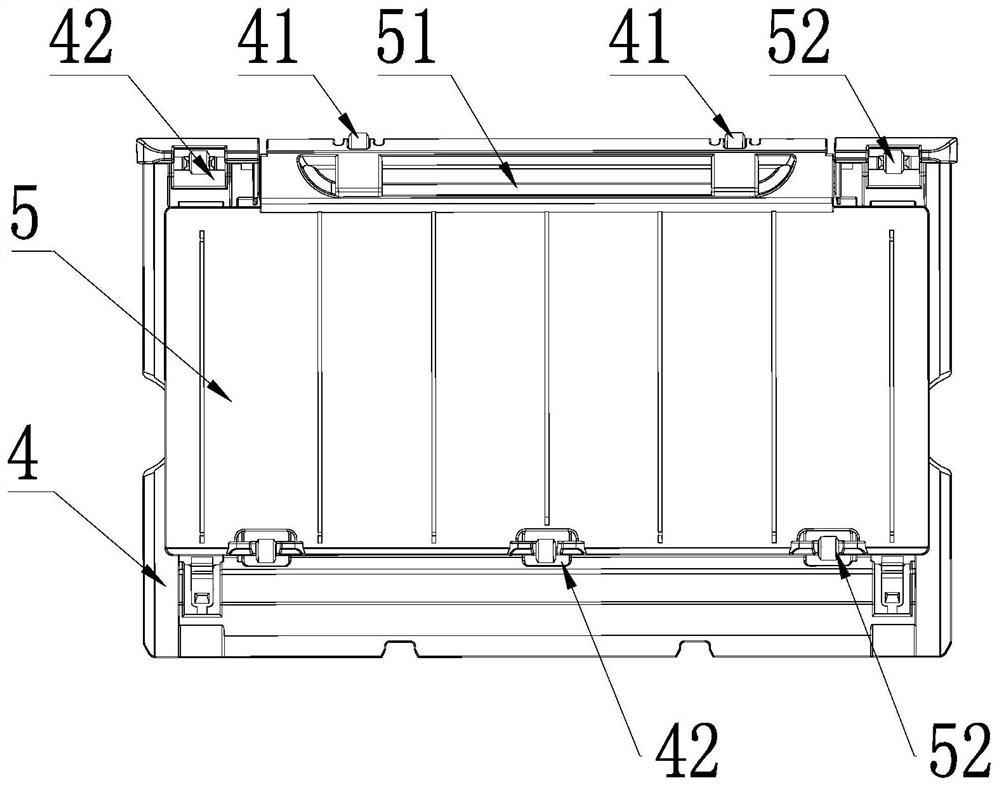

[0021]Such asFigure 1-5As shown, this embodiment relates to an auxiliary paper feeding device of a scanner, which includes a paper feeding platform 1, and paper feeding baffles 2 are provided on the left and right sides of the paper feeding platform 1.

[0022]In this embodiment, a paper pressing sheet 3 is provided on the paper feed baffle 2. The paper pressing sheet 3 and the paper feed baffle 2 are used to perform a preliminary limit pressing on both ends of the paper to prevent the entire stack of soft paper from collapsing during the scanning and feeding process.

[0023]The paper pressing sheet 3 is embedded in the inner side wall of the paper feed baffle 2 and is hinged to the inner side wall of the paper feed baffle 2. Through this design, when scanning ordinary paper, the paper pressing plate 3 can be received into the paper feeding baffle 2; when the soft paper needs t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com