Crop cooling and moisturizing device of agricultural planting greenhouse

A moisturizing device and crop technology, applied in the agricultural field, can solve the problems of plant dehydration, accelerate plant transpiration, burn plants, etc., and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

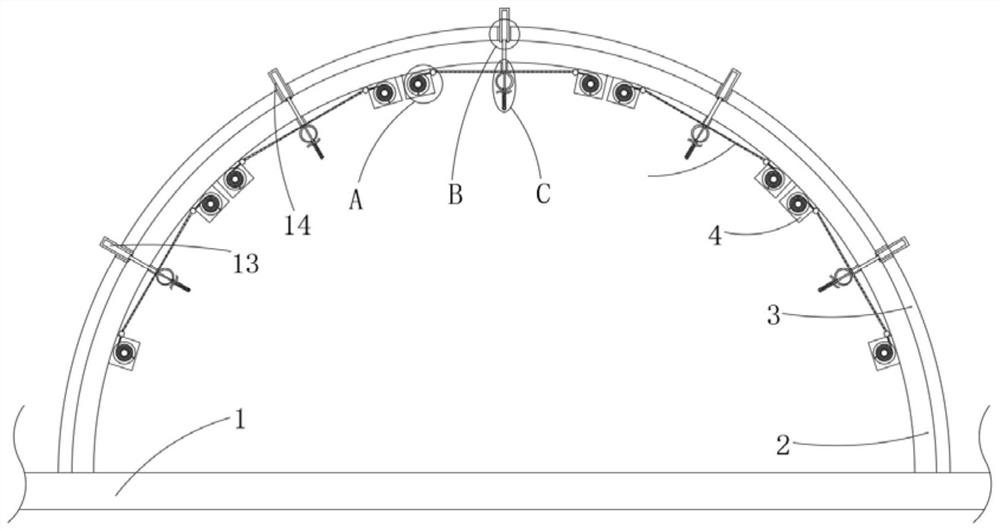

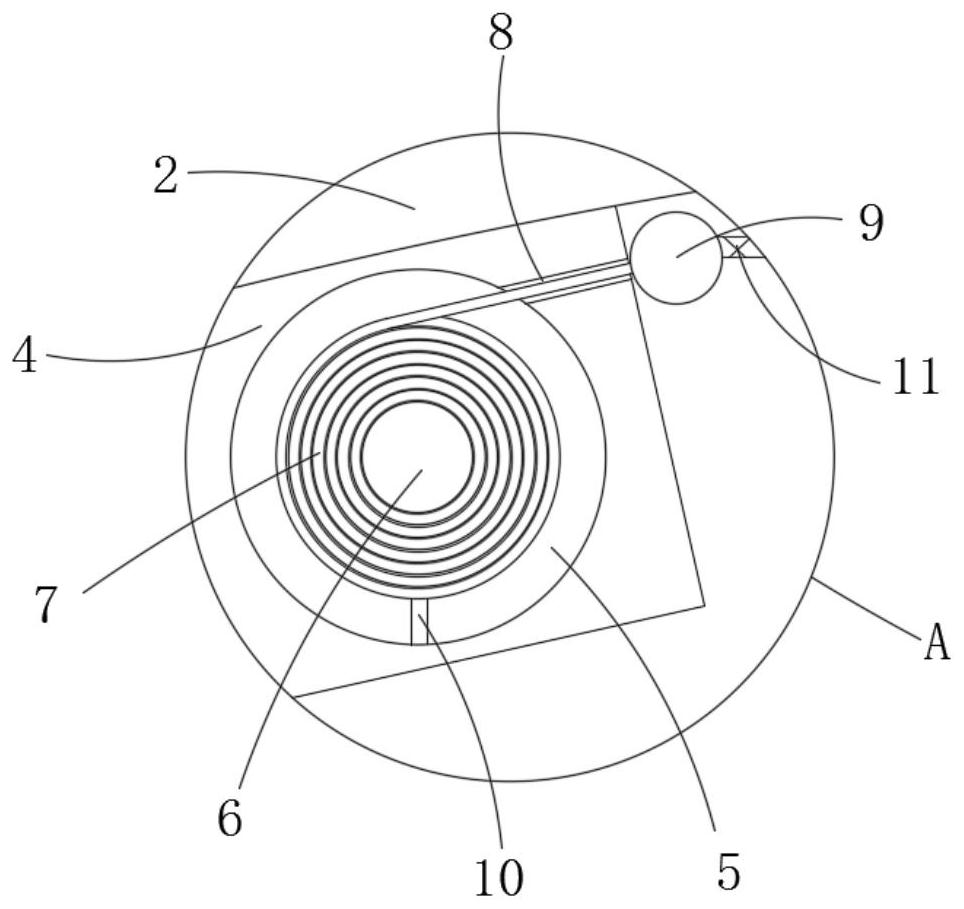

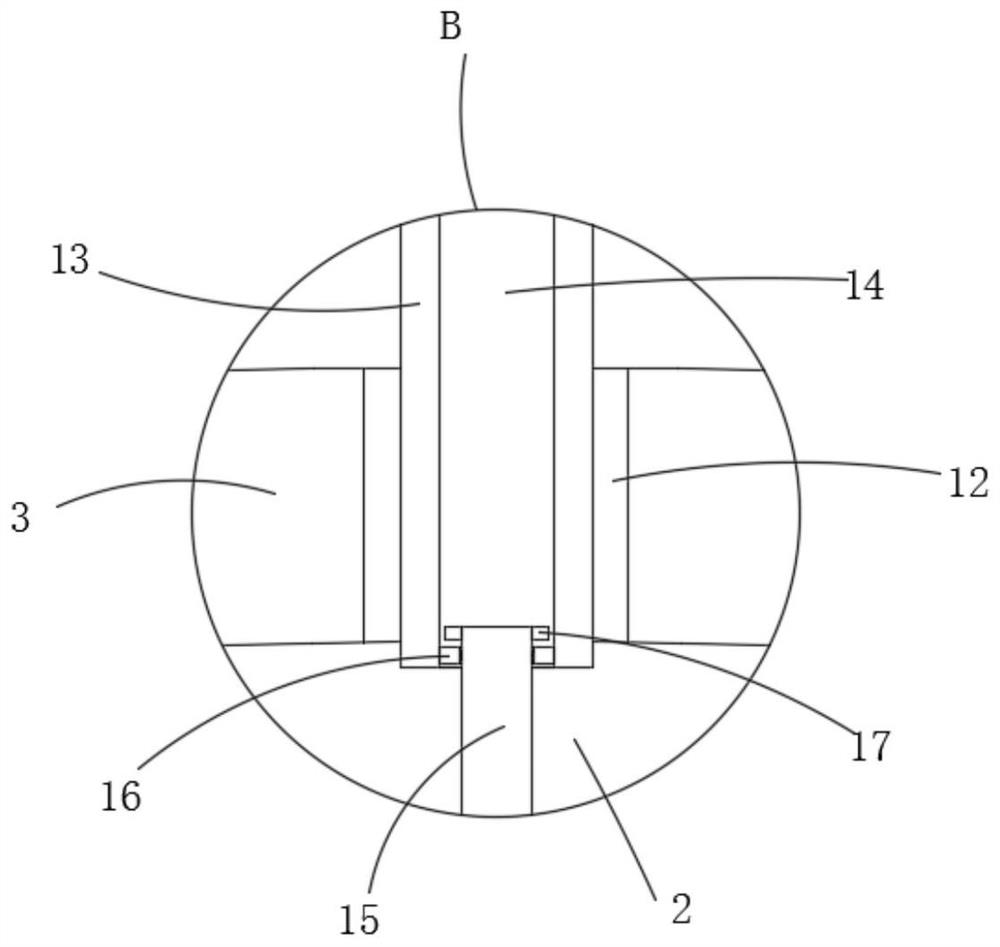

[0025] refer to figure 1 , figure 2 , image 3 with Figure 5 , a crop cooling and moisturizing device for agricultural planting greenhouses, comprising a plurality of skeletons 2 fixedly connected to the ground 1, the plurality of skeletons 2 are arranged at equal intervals, and the side walls of the plurality of skeletons 2 away from the ground 1 are jointly fixedly connected with The transparent film 3 and a plurality of skeletons 2 cooperate to complete the supporting work of the transparent film 3, thus successfully completing the construction of the greenhouse, and then completing the protection of the crops. There are a plurality of light processing devices arranged at equal intervals, and each of the plurality of light processing devices includes two working columns 4 fixedly connected to a plurality of skeletons 2, and the two working columns 4 are arranged symmetrically to each other. Both are provided with a working chamber 5, and a rotating rod 6 is rotatably c...

Embodiment 2

[0031] refer to figure 1 with Figure 4 The difference between this embodiment and Embodiment 1 lies in the setting of multiple water supply devices. Multiple water supply devices are provided on multiple skeletons 2. The multiple water supply devices are respectively matched with multiple light processing devices. Each water supply device includes The water delivery pipe 18 is connected with the external water supply equipment, and there is enough water inside for irrigation. The water delivery pipe 18 is fixedly connected to a plurality of skeletons 2 through a plurality of connecting rods 19, and the water delivery pipe 18 is close to the outer wall of the side of the ground 1 A water spray pipe 20 is fixedly connected to the top, and one end of the water spray pipe 20 near the ground 1 is provided with a plurality of water spray holes 21. The side wall is provided with a plurality of sliding holes 22, and the plurality of sliding holes 22 are respectively connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com