Vegetable cleaning production line

A production line and vegetable technology, applied in the field of live vegetable cleaning equipment, can solve the problems of secondary pollution of vegetables, inclusion of impurities, inability to separate vegetables and cleaning water, etc., to improve cleanliness, reduce quantity, and reduce secondary pollution. effect of probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following is attached Figure 1-11 The application is described in further detail.

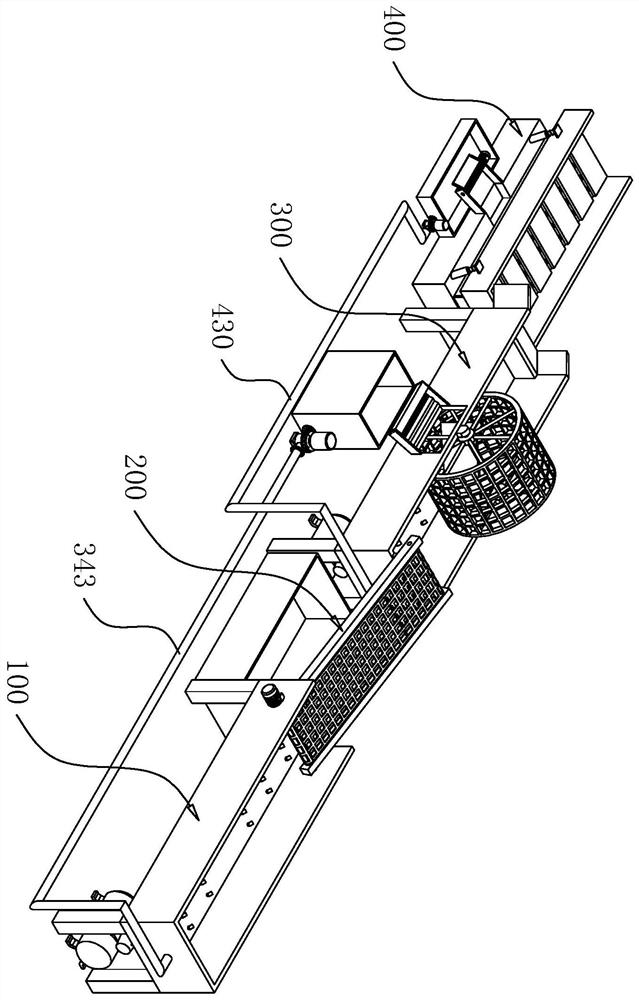

[0045] The embodiment of the present application discloses a vegetable cleaning production line. refer to figure 1 , the vegetable cleaning production line includes a sediment cleaning machine 100 for cleaning sediment on vegetables, a crushed vegetable leaf separator 300 for separating vegetables and crushed vegetable leaves, and a water vegetable separator 400 for separating cleaning water from vegetables The sediment cleaning machine 100 is connected to the crushed vegetable leaf separator 300 through the conveying device 200, and the crushed vegetable leaf separator 300 is connected to the water vegetable separator 400.

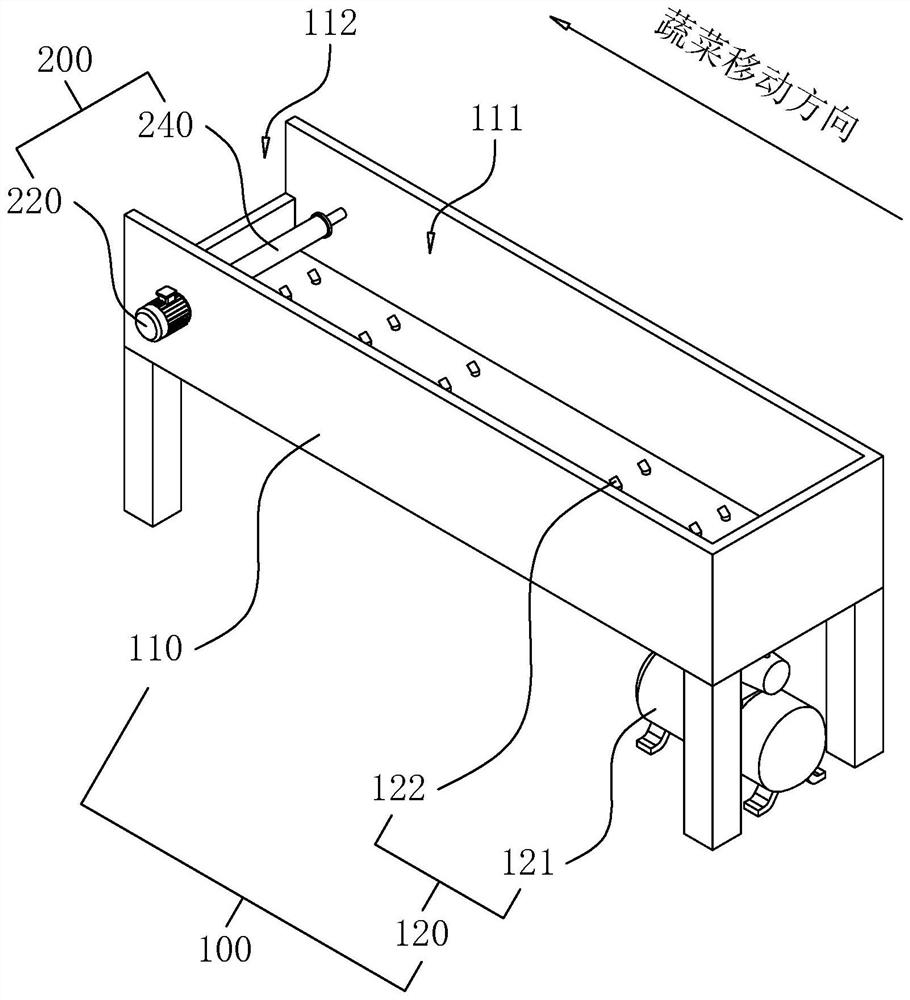

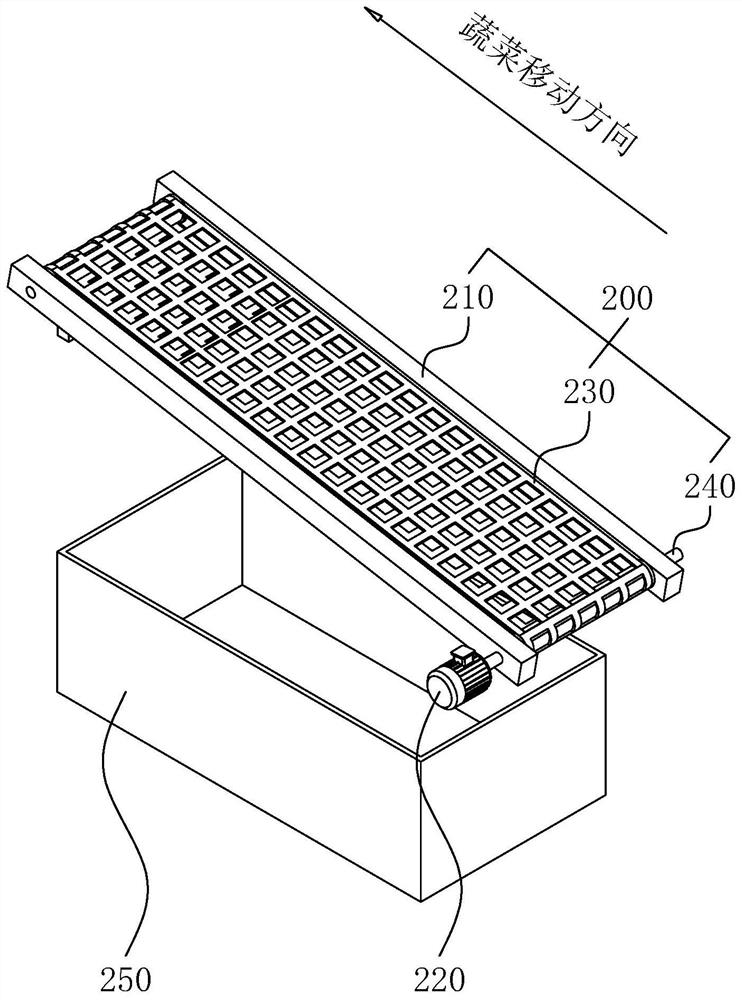

[0046] refer to figure 1 and figure 2 , The sediment cleaning machine 100 includes a first frame 110, and a first cleaning tank 111 is opened on the first frame 110, and the first cleaning tank 111 is filled with cleaning water. The two ends of the length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com