A construction fiberglass oiling and wrapping device

A fiberglass and cloth wrapping technology, which is applied to spraying devices and other directions, can solve the problems of slow painting and wrapping speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

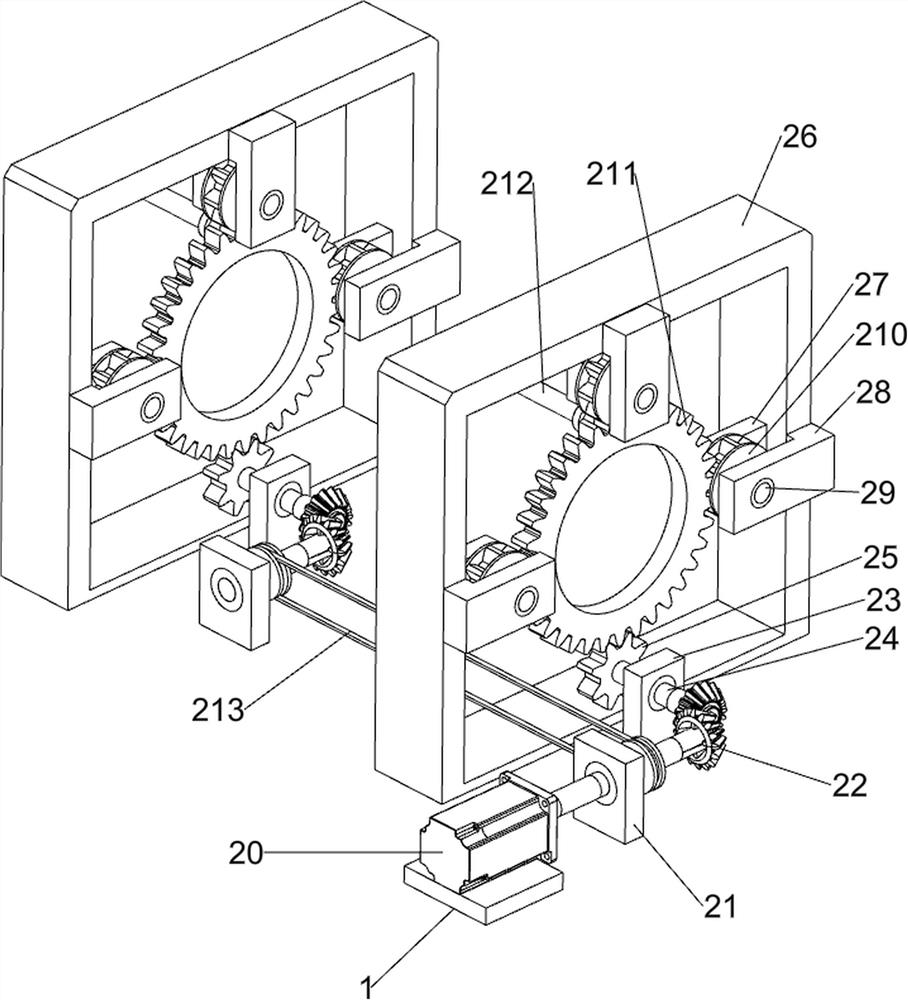

[0025] An architectural glass fiber reinforced plastic oiling and wrapping device, such as Figure 1-8 As shown, it includes a base 1, a cloth wrapping mechanism 2 and a paint spraying mechanism 3. The upper left side of the base 1 is provided with a cloth wrapping mechanism 2, and the upper left side of the base 1 is provided with a paint spraying mechanism 3. The cloth wrapping mechanism 2 cooperates with the spraying mechanism 3.

[0026] When the user needs to oil and wrap the FRP, he can use this equipment. First, place the FRP on the wrapping mechanism 2 and the spraying mechanism 3. Since the wrapping mechanism 2 and the spraying mechanism 3 are crossed, the user can manually Push the FRP to move to the left, pass through the cloth wrapping mechanism 2 and the paint spraying mechanism 3 in turn, and under the cooperation of the cloth wrapping mechanism 2 and the paint spraying mechanism 3, the FRP is oiled and wrapped.

Embodiment 2

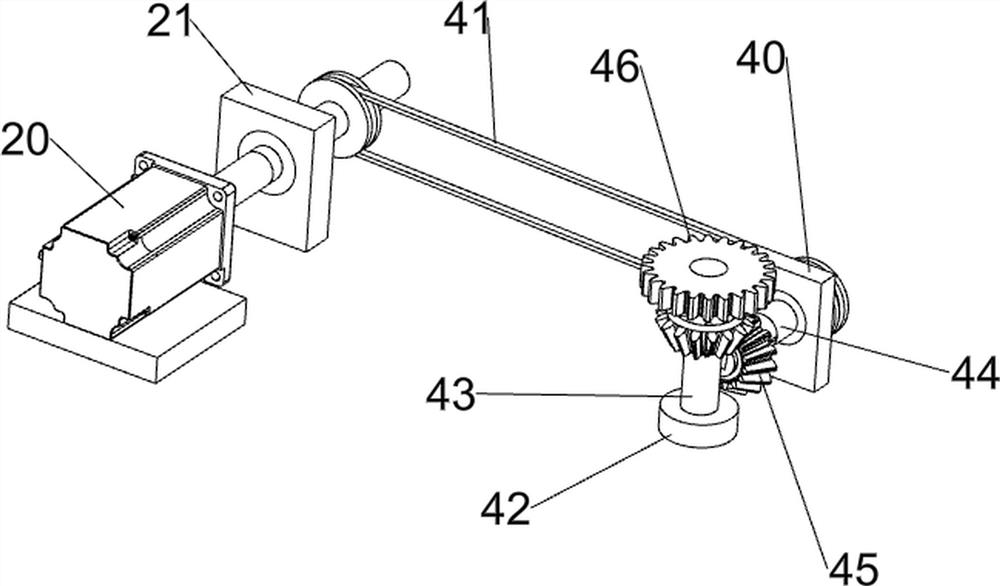

[0028] On the basis of Example 1, as figure 2As shown, the wrapping mechanism 2 includes a servo motor 20, a first bearing seat 21, a first bevel gear set 22, a second bearing seat 23, a first rotating shaft 24, a first gear 25, a mounting frame 26, and a third bearing seat 27. The fourth bearing seat 28, the second rotating shaft 29, the second gear 210, the third gear 211, the discharge rod 212 and the first pulley assembly 213, the upper part of the base 1 is provided with a servo motor 20 in the middle of the front side, and the front of the upper part of the base 1 A first bearing seat 21 is arranged symmetrically on the side and left, the output shaft of the servo motor 20 passes through the first bearing seat 21 on the right side, and a second bearing seat 23 is arranged symmetrically on the front side of the upper part of the base 1. The bearing seat 21 and the second bearing seats 23 on both sides are rotatably provided with first rotating shafts 24 , and the two fir...

Embodiment 3

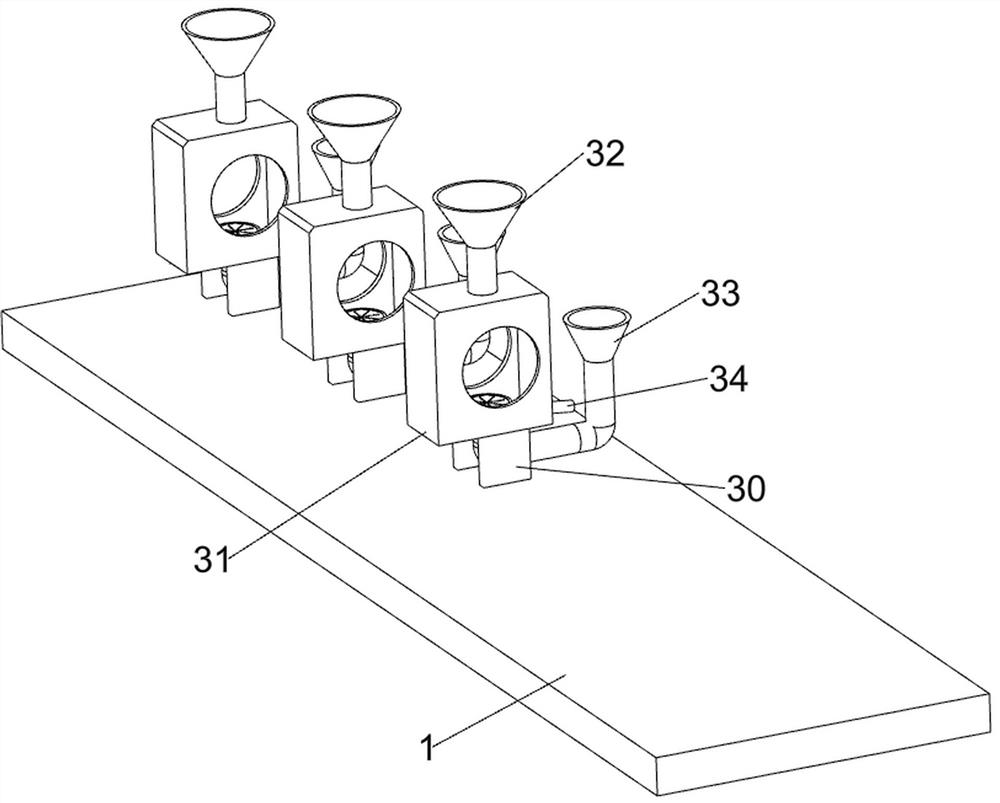

[0031] On the basis of Example 2, as Figure 3-4 As shown, the paint spraying mechanism 3 includes a support plate 30, a protective frame 31, an upper spray pipe 32, a lower spray pipe 33 and a discharge pipe 34. Three support plates 30 are evenly arranged on the left side of the upper part of the base 1, and the upper part of the support plate 30 is provided with There is a protective frame 31, the upper part of the protective frame 31 is provided with an upper nozzle 32, the rear part of the protective frame 31 is provided with a lower nozzle 33, the rear part of the protective frame 31 is connected with a discharge pipe 34, and the discharge pipe 34 is connected with the protective frame. 31 Connected.

[0032] The user can pass the FRP through the protective frame 31, and then spray the FRP evenly through the upper nozzle 32 and the lower nozzle 33. The excess paint on the FRP will fall into the protective frame 31 and flow out through the discharge pipe 34. The user can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com