Intelligent ultrasonic washing machine for castings in investment casting method

An investment casting and ultrasonic technology, applied in the field of casting production equipment, can solve the problems of inconvenient disassembly and maintenance of heating equipment, inconvenient work of workpiece fixing, inconvenient filtering and cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

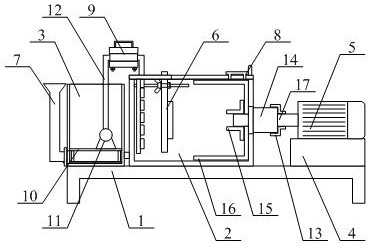

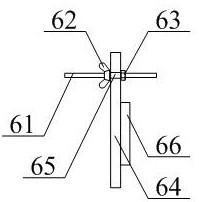

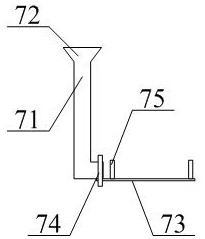

[0036] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, the intelligent investment casting ultrasonic cleaning machine includes a fixed seat 1, a cleaning tank 2, a water tank 3, a connecting seat 4, a rotating motor 5, a movable fixed plate rod structure 6, and a filter plate structure 7 that can be filled , slidable plug-in ultrasonic plate structure 8, detachable maintenance heating seat structure 9, filter plate 10, self-priming pump 11, inverted U-shaped tube 12, T-shaped shielding tube 13, upper sleeve 14, inner sleeve 15, outer sleeve The sleeve 16 and the rotating shaft 17, the cleaning tank 2 is bolted to the upper middle position of the fixed seat 1; the water tank 3 is bolted to the upper left middle position of the fixed seat 1; the connecting seat 4 is bolted to At the middle position on the upper right side of the fixed base 1; the rotating motor 5 is bolted to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com