Sintering forming method of steel sample with impurities implanted manually

An inclusion and artificial technology, which is applied in the field of sintering and forming of steel samples with artificially implanted inclusions, can solve the problems of inability to accurately locate inclusions, the combination of inclusions and metals, and the influence of accuracy, so as to simplify the sample preparation operation. Difficulty, improve preparation efficiency, improve the effect of precision and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a sintering forming method of a steel sample artificially implanted with inclusions:

[0038] Among them, the steel sample is a 304 stainless steel cylinder sample with a diameter of 10 mm and a height of 15 mm. Artificially implanted inclusions are Al 2 o 3 , which is a cube with side length 2 mm. The Al 2 o 3 The preset implantation position of the inclusion is the center of the 304 stainless steel cylinder sample.

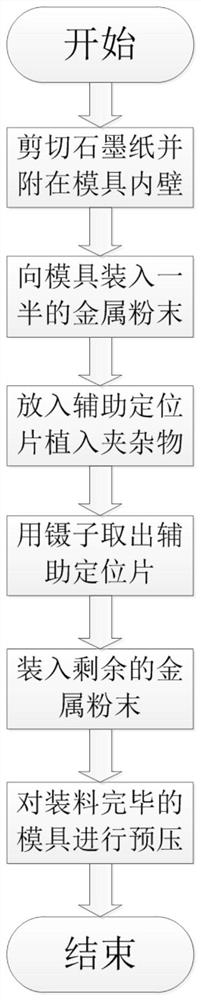

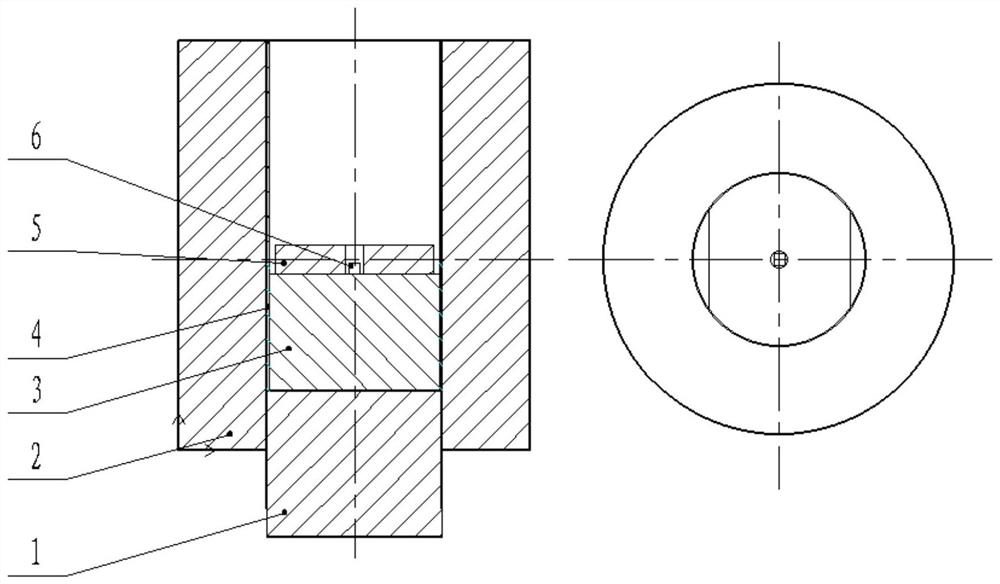

[0039] The specific implementation process is as follows, such as figure 1 with figure 2 Shown:

[0040] 1. Select the appropriate graphite mold and indenter according to the specific size of the stainless steel cylindrical sample to be prepared, and prepare the graphite paper used for demoulding the metal sample;

[0041] 2. Cut the graphite paper 4 to a suitable size and cover it on the inner wall of the graphite mold. The purpose of this is to make the metal sample demould smoothly after the sintering is completed;

...

Embodiment 2

[0053] This embodiment provides a sintering forming method of a steel sample artificially implanted with inclusions:

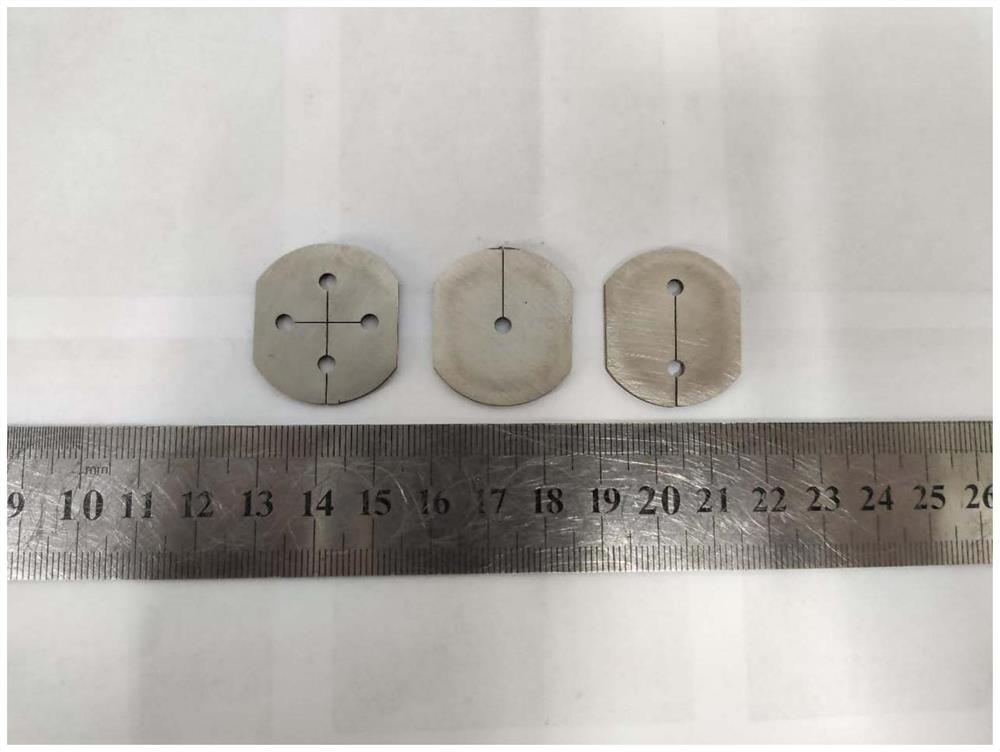

[0054] Among them, the steel sample is a 304 stainless steel cylinder sample with a diameter of 30 mm and a height of 26 mm. Artificially implanted inclusions are Al 2 o 3 , which is a sphere with a diameter of 2 mm. In this embodiment, a total of four spherical inclusions were implanted, which were respectively distributed in the circumferential direction of the stainless steel sample at a distance of 7.5 mm from the center of the circle.

[0055] The specific implementation process is as follows:

[0056] 1. Select the appropriate graphite mold and indenter according to the specific size of the stainless steel cylindrical sample to be prepared, and prepare the graphite paper used for demoulding the metal sample;

[0057] 2. Cut the graphite paper 4 into a suitable size and cover it on the inner wall of the graphite mold. The purpose of this is to make th...

Embodiment 3

[0071] This embodiment provides a sintering forming method of a steel sample artificially implanted with inclusions:

[0072] Among them, the steel sample is a 304 stainless steel cylinder sample with a diameter of 30 mm and a height of 26 mm. Artificially implanted inclusions are Al 2 o 3 , which is a sphere with a diameter of 2 mm. In this embodiment, a total of two spherical inclusions were implanted, which were respectively distributed in the circumferential direction of the stainless steel sample at a distance of 7.5 mm from the center of the circle.

[0073] The specific implementation process is as follows:

[0074] 1. Select the appropriate graphite mold and indenter according to the specific size of the stainless steel cylindrical sample to be prepared, and prepare the graphite paper used for demoulding the metal sample;

[0075] 2. Cut the graphite paper 4 into a suitable size and cover it on the inner wall of the graphite mold. The purpose of this is to make the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com