Hollow frame part machining method

A part processing and frame technology, applied in the field of hollow frame parts processing, can solve the problems of difficult to guarantee dimensional accuracy, inconvenient positioning and clamping, material waste, etc., to save material costs and processing costs, dimensional accuracy is stable and reliable, and the process flow Reasonably compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

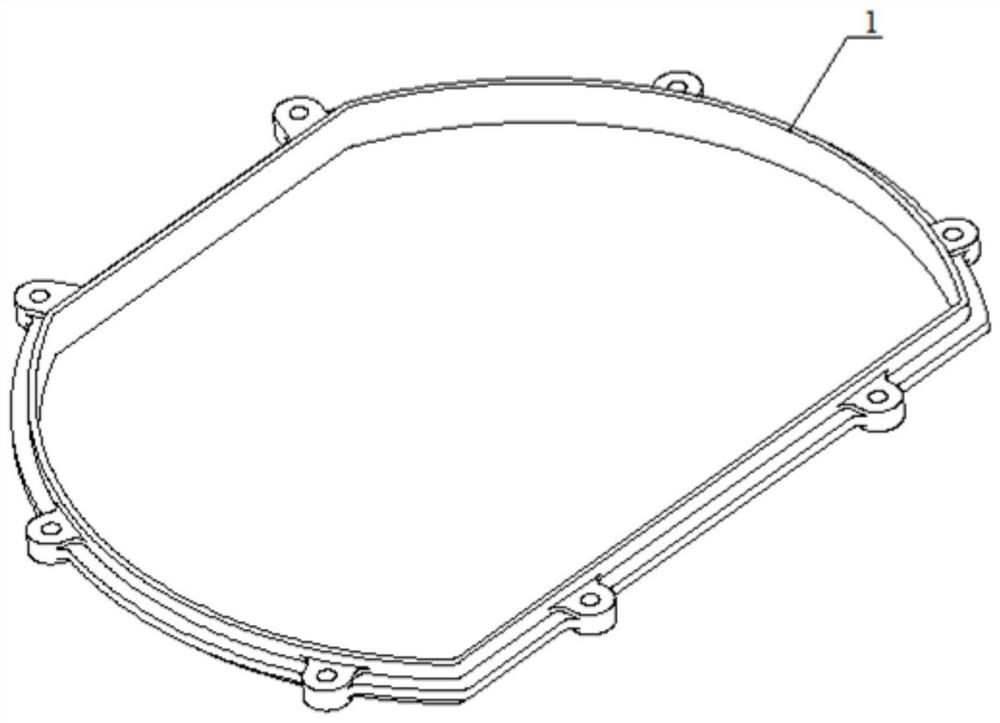

[0037] Using the above scheme, processing such as figure 1 Hollow frame parts shown. The actual operation mainly includes the following steps:

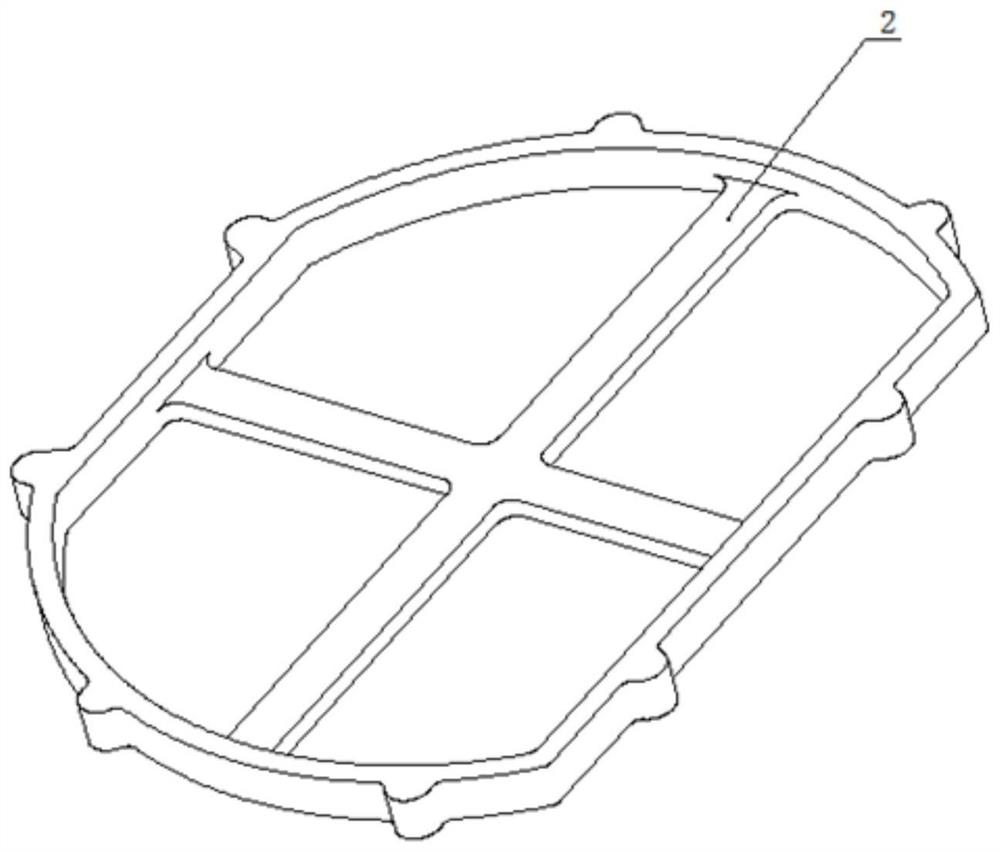

[0038] 1. Casting process: ZL101-T6 cast aluminum alloy is selected and cast into such figure 2 The flat annular blank shown has the same shape as figure 1 The parts shown have the same shape, and the blank size is 1mm-2mm larger than the part size on one side. The middle part of the blank is hollowed out, and cross-shaped ribs 2 are evenly arranged in the hollowed-out inner cavity. The cross-shaped ribs are flush with the bottom surface of the blank, and the thickness of the cross-shaped ribs is 1 / 3-1 / 2 of the thickness of the blank. Parallel and perpendicular to the two flat sides of the blank.

[0039] 2. Turning processing: Symmetrical turning processing of both ends of the surface, so that the removal allowance of the two ends of the surface is consistent, and the thickness after processing is consistent with the total thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com