Full-automatic bamboo cane feeding device

A fully automatic, bamboo strip technology, applied in workpiece feeding devices, processing machines for manufacturing flat surfaces, wood processing appliances, etc., can solve problems such as high labor intensity, hidden safety hazards, and limit the production efficiency of planer machines, and achieve automation High degree, the effect of increasing the feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments of the description:

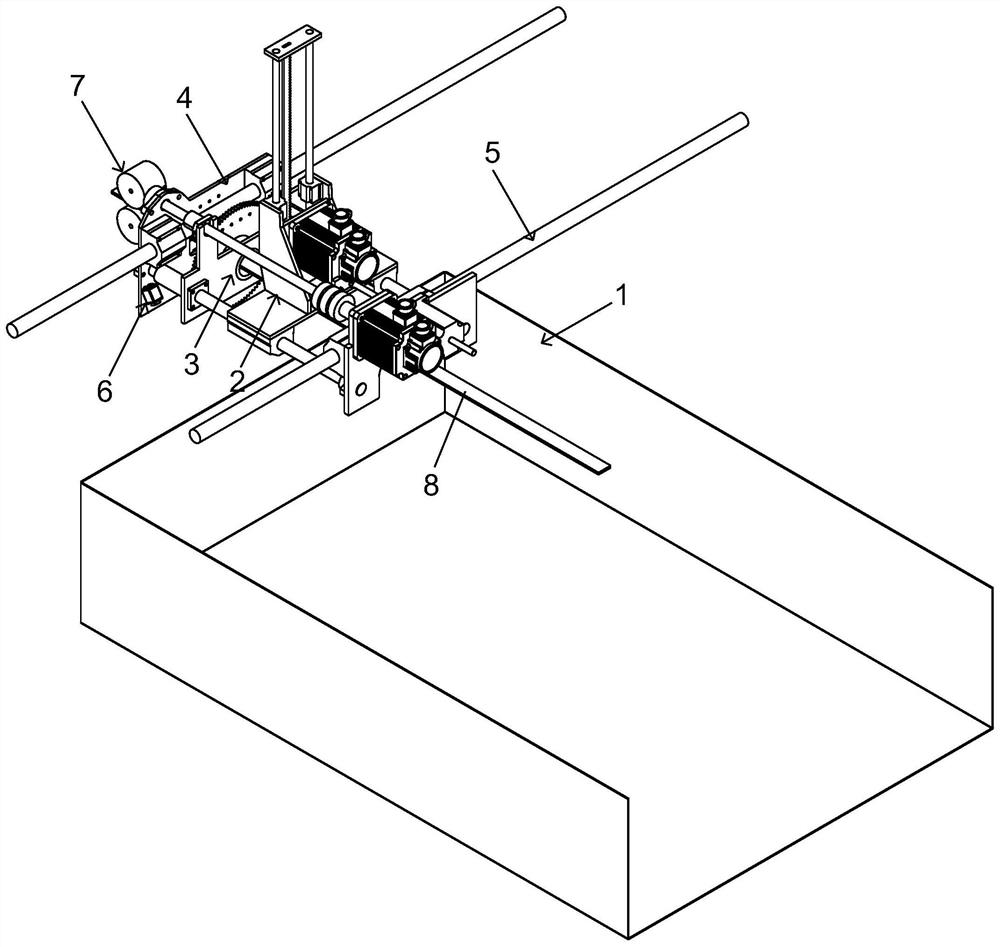

[0022] Such as Figure 1-6 Shown is a schematic diagram of an embodiment of a fully automatic bamboo stick feeding device provided by the present invention.

[0023] A fully automatic bamboo strip feeding device, which includes a feeding mechanism 1, a material grabbing mechanism 2 and a pulling mechanism 3;

[0024] The feeding mechanism 1 includes a feeding frame for stacking bamboo strips; the bamboo strips are horizontally placed in the feeding frame, and the front end of the bamboo sticks against the front baffle of the feeding frame.

[0025] The front side of the feeding frame is inclined downwards, and a vibrating part is arranged on it.

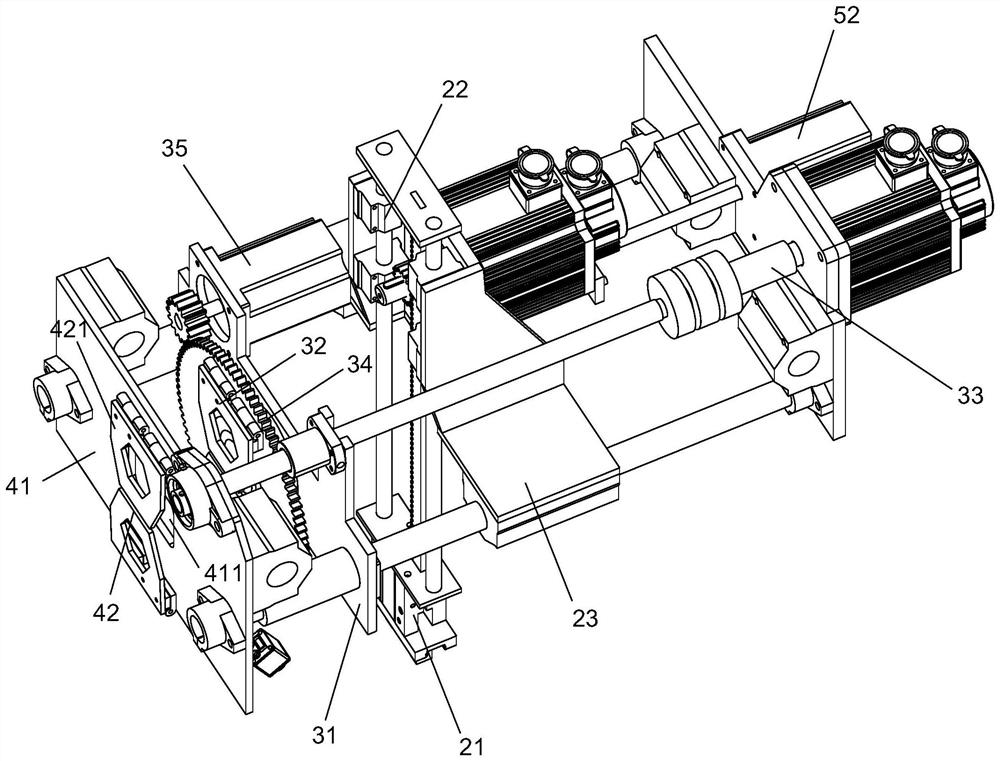

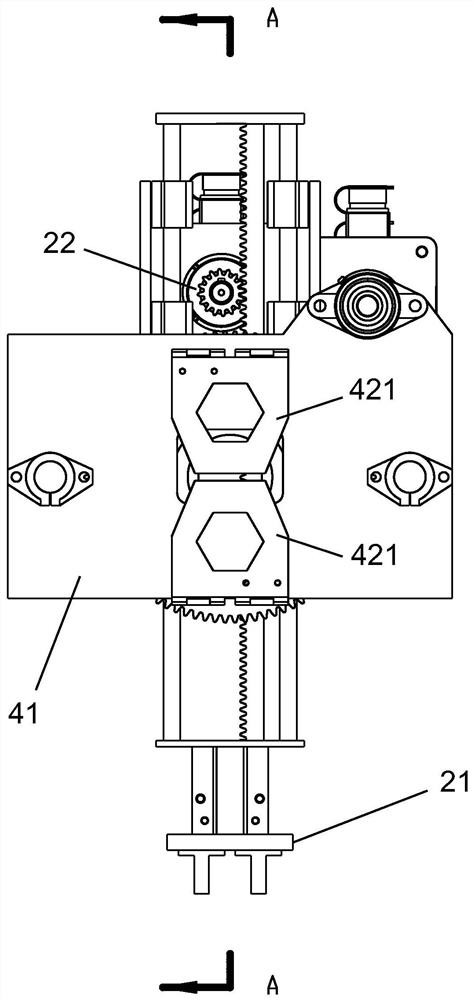

[0026] The grasping mechanism 2 includes a grasping part 21 for clamping the left and right sides of the bamboo strips, a lifting assembly 22 for driving the vertical disp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap