Damping device and clothes treatment equipment

A technology of clothing processing equipment and shock absorption device, applied in the field of washing machines, can solve problems such as reducing user experience, and achieve the effects of reducing vibration noise and controlling vibration amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

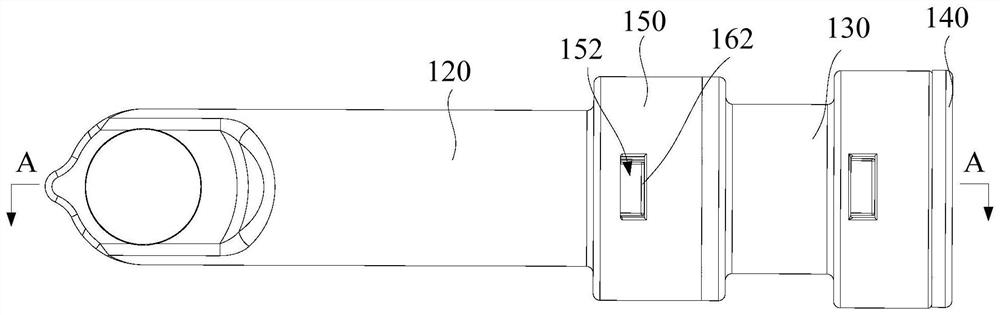

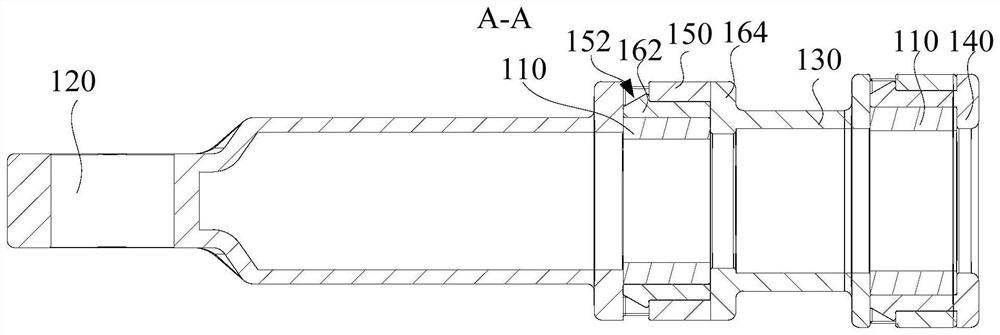

[0051] Such as figure 1 and figure 2 As shown, the embodiment of the first aspect of the present invention provides a shock absorbing device, the shock absorbing device includes a plurality of bushings, a piston rod and at least two damping elements 110, wherein each bushing in the plurality of bushings The tubes are connected in sequence, the piston rod is movably inserted in a plurality of sleeves, at least two damping elements 110 are respectively arranged in at least two of the plurality of sleeves, and the piston rod can be in contact with at least two damping elements 110 .

[0052] The shock absorbing device provided by the embodiment of the present invention includes a plurality of bushings, piston rods and at least two damping elements 110. Specifically, each bushing is detachably connected in sequence for easy installation and dismounting. In addition, in the shock absorbing device When a certain bushing among the multiple bushings breaks down, the failed bushing ...

Embodiment 2

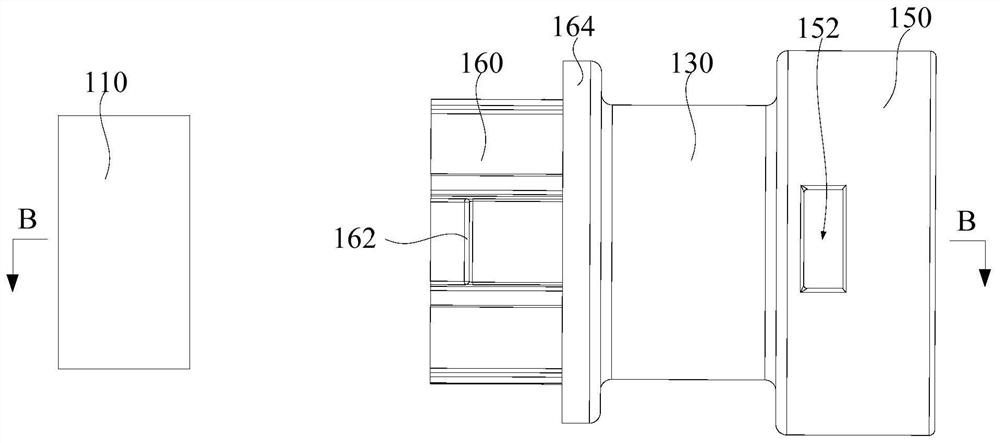

[0056] Such as figure 2 , image 3 and Figure 4As shown, on the basis of the above embodiments, further, the multiple sleeves include a first sleeve 120 and at least one second sleeve 130, wherein one end of the first sleeve 120 is used to connect with the equipment to be damped , the other end of the first sleeve 120 is provided with a first connecting portion 150, and one end of any one of the second sleeves 130 in at least one second sleeve 130 is provided with a second connecting portion 160, and at least one of the second sleeves 130 The second connection portion 160 of the first second sleeve 130 is connected to the first connection portion 150 of the first sleeve 120 .

[0057] In this embodiment, the plurality of sleeves include a first sleeve 120 and at least one second sleeve 130, specifically, one end of the first sleeve 120 is used to connect with the laundry treatment equipment, for example, the first sleeve 120 One end of 120 can be fixedly installed on the ...

Embodiment 3

[0061] On the basis of any of the above-mentioned embodiments, the connection structure of multiple sleeves is specifically explained and described. Further, the other end of any one of the second sleeves 130 in at least one second sleeve 130 is provided with a first connection part 150, when the number of at least one second bushing 130 is at least two, along the direction in which the piston rod pulls out a plurality of bushings, the first connection of any one of the at least two second bushings 130 The portion 150 is connected to the second connection portion 160 of the second sleeve 130 located behind it.

[0062] In this embodiment, the structure and connection method of the second sleeve 130 are specifically defined, specifically, the other end of the second sleeve 130 is provided with a first connection portion 150, that is, each second sleeve Both ends of 130 are respectively provided with a first connection part 150 and a second connection part 160 , and the first co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com