Guide vane body with splitter vanes

A technology of guide vane body and diverter vane, which is applied in the field of diverter guide vanes, which can solve the problems of weakened energy conversion capacity of guide vanes, small thickness of guide vane blades, and increased displacement of guide vanes, so as to reduce vortex area and strength, and improve flow state, effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The purpose and effects of the present invention will be more obvious by describing the present invention in detail below in conjunction with the accompanying drawings and embodiments.

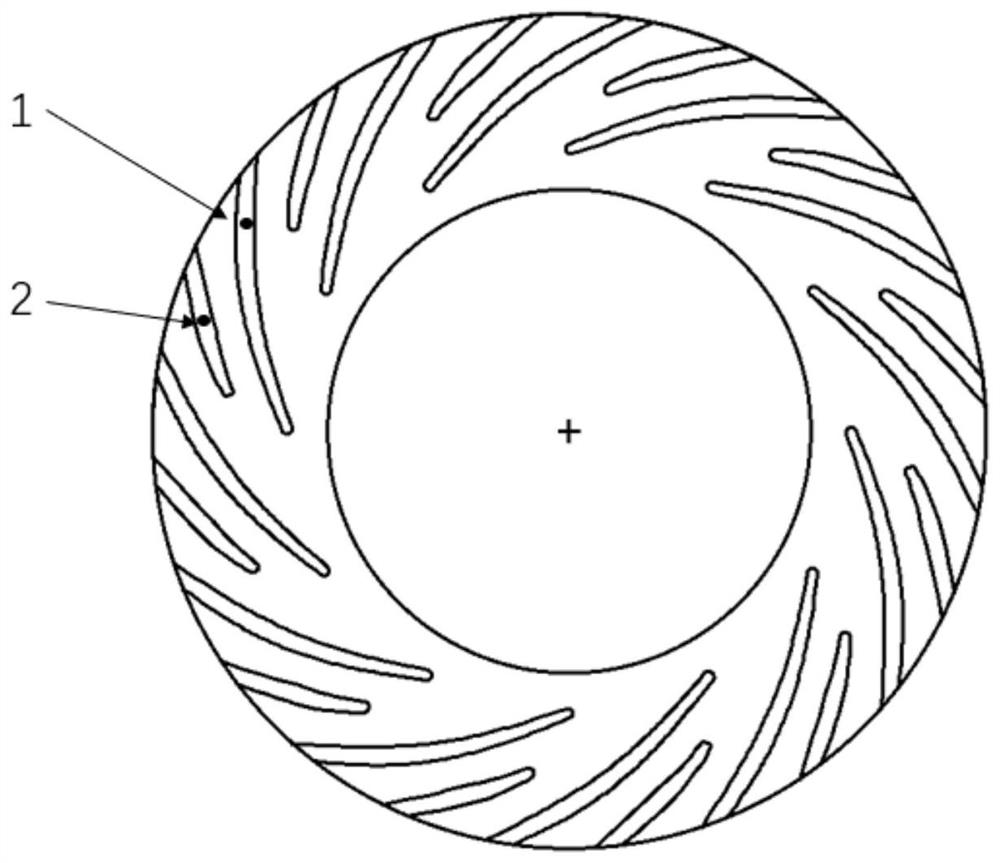

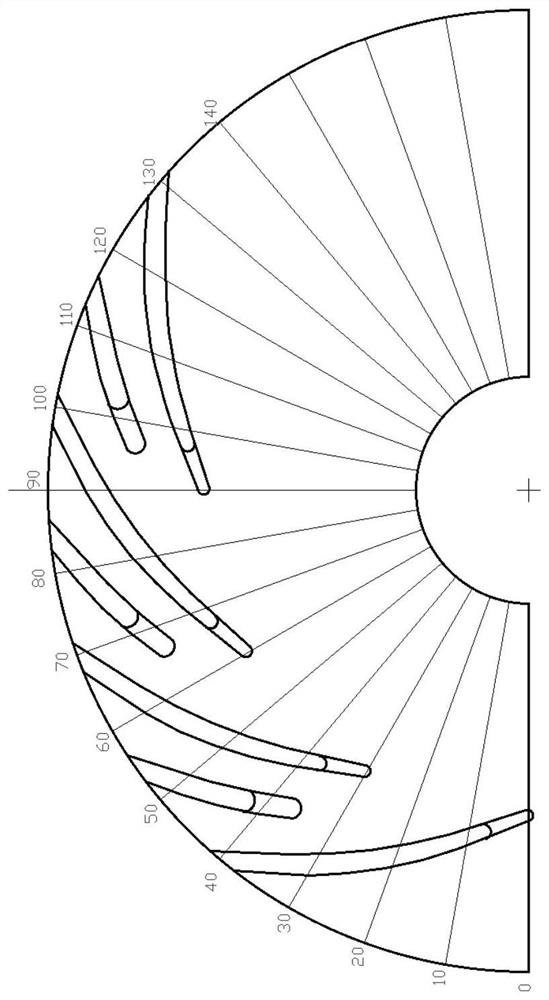

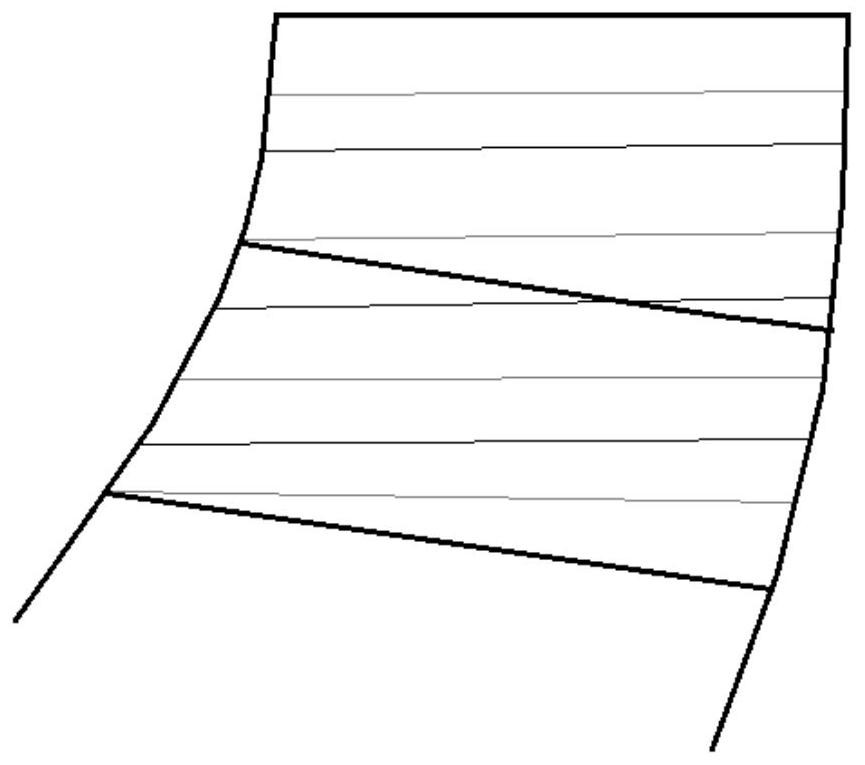

[0013] Such as figure 1 As shown, on the premise of not changing other main components of the pump, the inner guide vane is replaced and the auxiliary vane 2 is added. The splitter guide vane of the present invention includes a main vane 1 and an auxiliary vane 2 . The scheme adopted in this embodiment is that the auxiliary blade 2 is offset into the flow channel, and the offset angle is 15°. The length of the auxiliary blade 2 is 0.5 times the length of the main blade 1. After the auxiliary blade 2 is added, under the interference of the auxiliary blade , the shedding vortex at the trailing edge of the main blade is suppressed, the flow at the outlet of the guide vane channel is more uniform, the flow loss is reduced, and the flow state is improved, thereby improving the performance o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com