Hydraulic engineering pipeline maintenance device

A technology for water conservancy projects and pipelines, which is used in pipeline laying and maintenance, lifting devices, pipe components, etc., can solve the problems of difficult alignment, low work efficiency, and insufficient stability of manual pipe support, and achieves simple structure, convenient transportation, The effect of reducing space occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

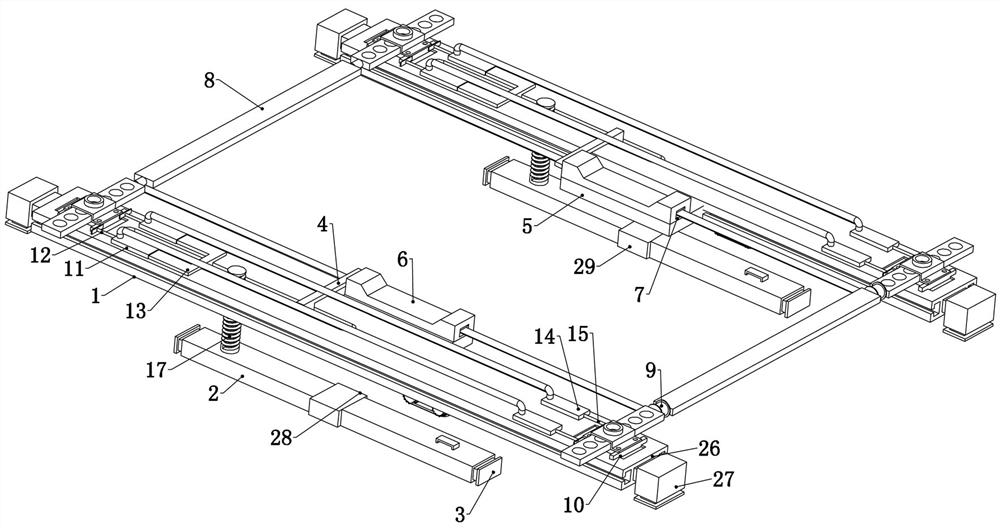

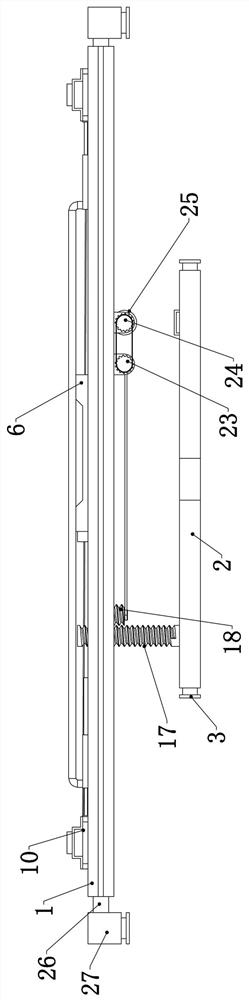

[0041] Embodiment 1, the present invention is a water conservancy pipeline maintenance device, which is characterized in that it includes two support beams 1, the two support beams 1 are placed on the ground and span the excavated pipe culvert, and the two support beams 1 are used for subsequent The structure provides a fixed foundation, the lower ends of the two supporting beams 1 slide up and down and are connected with a positioning beam 2, and the positioning beam 2 is placed in the excavated pipe culvert, and both ends of the two positioning beams 2 are fixedly connected with positioning beams. The hydraulic cylinder 3, the two positioning hydraulic cylinders 3 on each positioning beam 2 are synchronously controlled by the positioning hydraulic pump fixedly connected to the corresponding positioning beam 2, the positioning hydraulic pump can drive the two positioning hydraulic cylinders 3 to extend out synchronously, The two positioning hydraulic cylinders 3 are in contact...

Embodiment 2

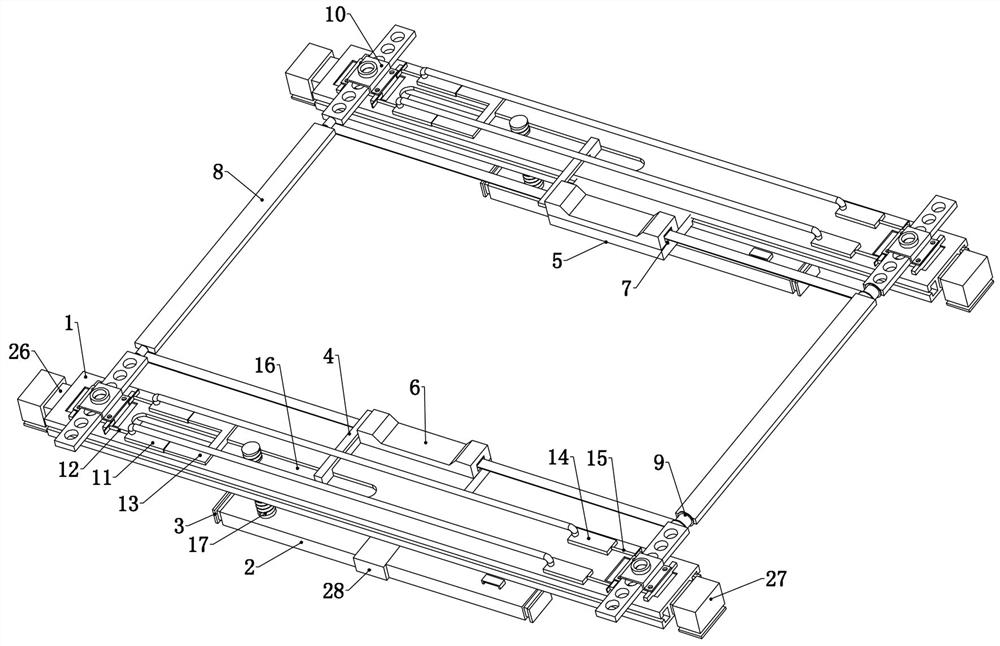

[0045] Embodiment 2. On the basis of Embodiment 1, this embodiment provides a structure in which the vertical beam 8 moves synchronously with the positioning beam 2, so that after the bearing platform 5 breaks away from the support of the crossties 6, the replacement pipe is still located between the two vertical beams. The central position between the beams 8, so as to prevent the position of the replacement pipe from shifting when the steel wire rope supports the replacement pipe. For details, refer to image 3 , Figure 6 , Figure 7 , the two ends of the upper end of the supporting beam 1 are slidably connected to the vertical beam base 10, and one end of the two vertical beams 8 is fixedly connected to the vertical beam base 10, and the two ends of each vertical beam 8 are fixedly connected to the vertical beam base 10 respectively. On the two vertical beam bases 10 on the two supporting beams 1, refer to the specific fixing method Figure 6 , Figure 7 , the two ends ...

Embodiment 3

[0050] Embodiment three, on the basis of embodiment two, refer to Figure 5 , the two positioning bases 16 are slidably connected inside the two supporting beams 1, and the two positioning bases 16 are slidingly connected inside the supporting beam 1 and the lower end faces thereof are flush with the lower end faces of the supporting beams. The gear arm 4 and the drive push rod 13 are fixedly connected to the positioning base 16, that is, the movement of the positioning base 16 drives the gear arm 4 and the drive push rod 13 to move synchronously;

[0051] The positioning beam 2 is rotatably connected with a positioning screw 17, and the positioning screw 17 passes through the adjacent positioning base 16 and is screwed with it, and the positioning beam 2 is fixedly connected with a positioning motor. The positioning motor is connected with the positioning screw 17. Specifically, the positioning base 16 is provided with a threaded hole, and the positioning screw 17 passes thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com