Detection method for identifying water drops in seamless steel tube outer surface three-dimensional detection

A seamless steel pipe, three-dimensional inspection technology, applied in neural learning methods, measurement devices, image data processing and other directions, can solve the problems of real defect confusion, detection interference, false alarms of detection equipment, etc., to achieve suitable promotion and use, reduce detection errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

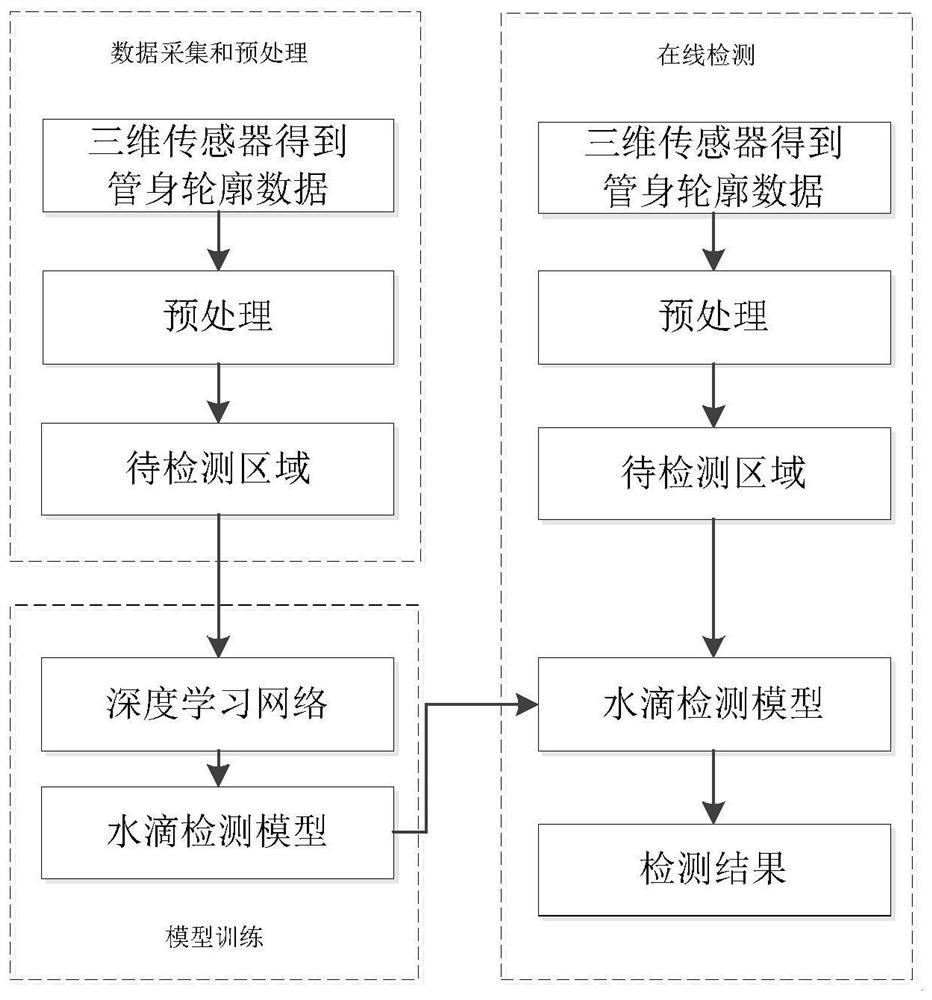

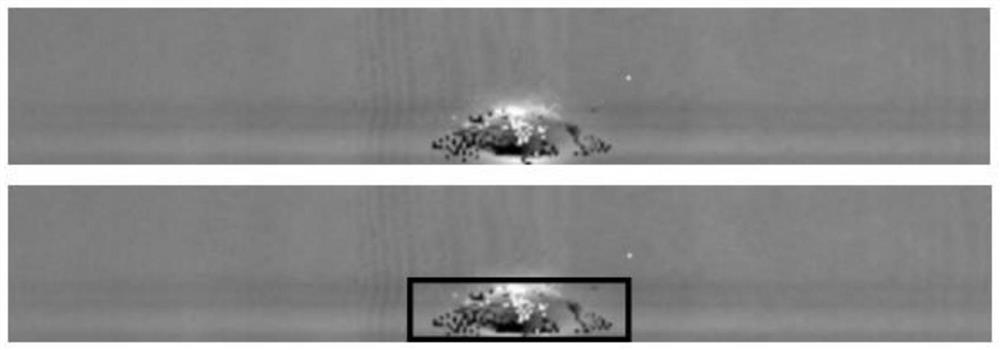

[0034] see Figure 1-3 , the present invention provides a technical solution:

[0035] A detection method for identifying water droplets in three-dimensional detection of the outer surface of a seamless steel pipe, comprising the following steps:

[0036] Step 1: Data preprocessing: According to the pipe body profile data obtained by the three-dimensional sensor, generate a two-dimensional grayscale image of the surface of the pipe body, and preprocess the grayscale image to obtain all areas to be detected;

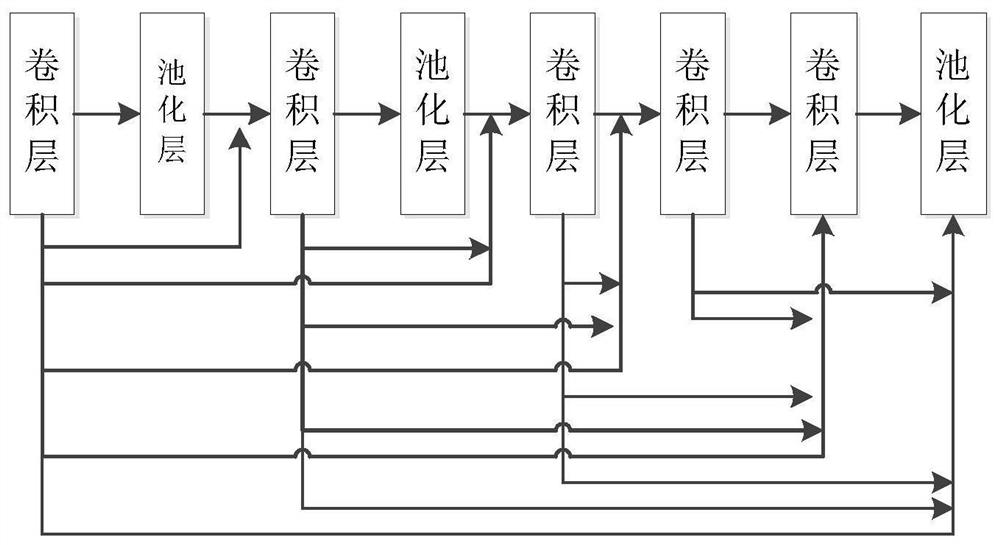

[0037] Step 2: Model training: construct a deep learning network suitable for detecting water droplets on the steel pipe surface offline, and train the model offline with the images of the area to be detected collected in step 1;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com