Printed circuit board detection method based on X-ray layering technology

A technology of printed circuit board and layering technology, applied in the field of testing equipment, can solve problems such as cost and multi-processing time, and achieve the effect of improving picture quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0037] As a preferred embodiment of the present invention, the step S5 specifically includes:

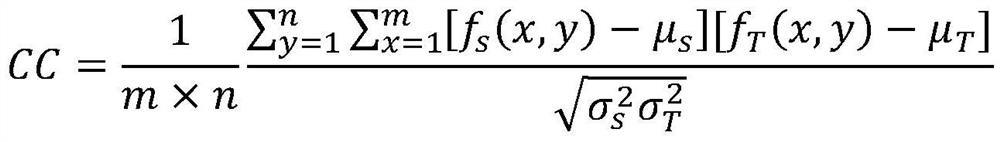

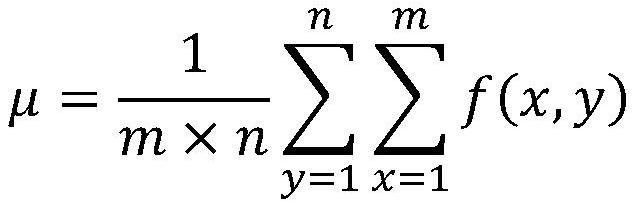

[0038] The correlation coefficient CC was determined using the following equation:

[0039]

[0040]

[0041]

[0042] where f s (x,y) and f T (x, y) are the gray levels of the reference image and the reconstructed image at a given image position (x, y), respectively, μ s and μ T is the average gray value of the reference image and the reconstructed image; and are the grayscale variances of the reference image and the reconstructed image, respectively.

[0043] Compared with prior art, the beneficial effect of the present invention is:

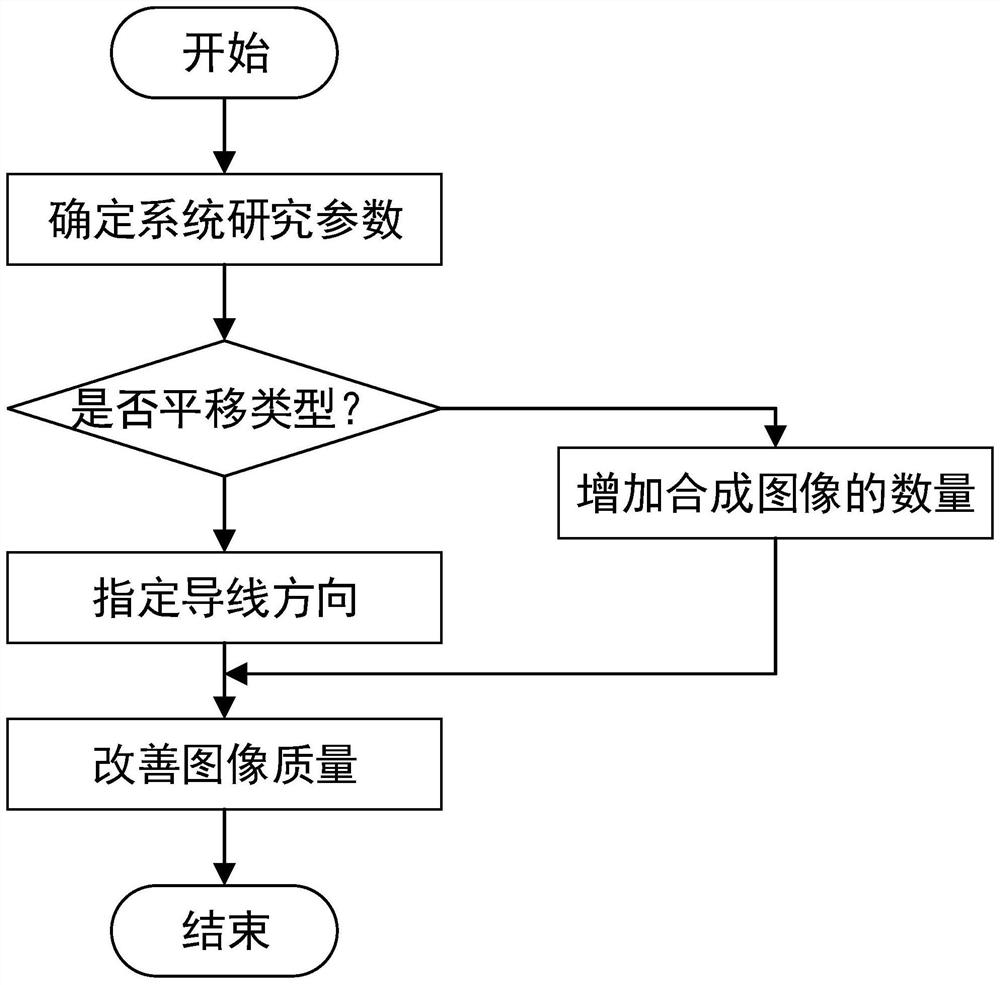

[0044] The beneficial effect of a printed circuit board detection method based on X-ray layering technology provided by the present invention is that the purpose of this study is to optimize the X-ray tomography technology for printed circuit board detection, and the system parameters studied include motion The type, the number of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com