Method and system device for preparing hydrogen for purifying fuel cell

A fuel cell and system device technology, applied in fuel cells, chemical instruments and methods, electrical components, etc., can solve the problems of achieving fuel cell purification goals, inability to hydrogen, and high purification costs, ensuring long-term stable operation and improving purification. The effect of precision and capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

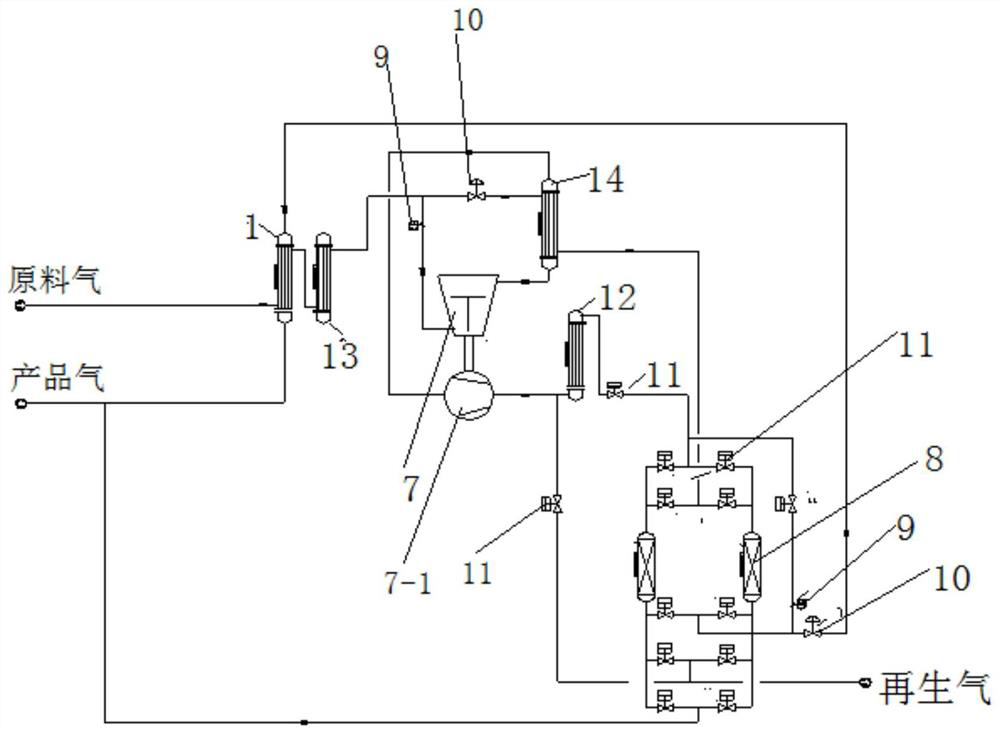

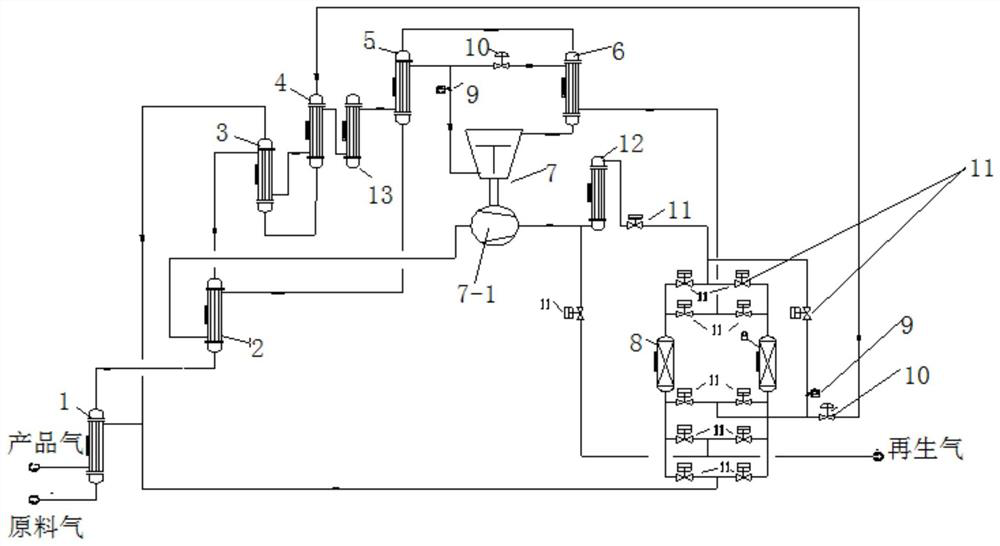

Image

Examples

Embodiment 1

[0038] A method for preparing and purifying hydrogen for fuel cells, the steps are as follows:

[0039] (1) The raw material hydrogen is lowered into low-temperature raw material hydrogen through the heat exchange mechanism I and the cooler; the raw material gas is purified hydrogen with a pressure of 2.5 MPa, a purity of 99.99% or more, and trace impurity indicators that do not meet the requirements of hydrogen for fuel cells. The specific content of trace impurities in the product gas needs to meet the national standard for pure hydrogen.

[0040] The temperature of the low-temperature raw material hydrogen is ≤ -150°C, and the cooler is a liquid nitrogen evaporative cooler. In front of the refrigeration mechanism, there is a cooler that operates at the initial stage of operation to cool down the hydrogen gas entering the refrigeration mechanism to -150°C to ensure the operation of the hydrogen refrigeration mechanism at the initial stage of operation.

[0041] (2) A part o...

Embodiment 2

[0045] A method for preparing and purifying hydrogen for fuel cells, the steps are as follows:

[0046] (1) The raw material hydrogen is lowered into low-temperature raw material hydrogen through the heat exchange mechanism I and the cooler; the raw material gas is purified hydrogen with a pressure of 1.6 MPa, a purity of 99.99% or more, and trace impurity indicators that do not meet the requirements of hydrogen for fuel cells. The specific content of trace impurities in the product gas needs to meet the national standard for pure hydrogen.

[0047] The temperature of the low-temperature raw material hydrogen is ≤ -160°C, and the cooler is a liquid nitrogen evaporative cooler. In front of the refrigeration mechanism, there is a cooler that operates at the initial stage of operation to cool down the hydrogen entering the refrigeration mechanism to -160°C to ensure the operation of the hydrogen refrigeration mechanism at the initial stage of operation.

[0048] (2) A part of th...

Embodiment 3

[0052] A method for preparing and purifying hydrogen for fuel cells, the steps are as follows:

[0053] (1) The raw material hydrogen is lowered into low-temperature raw material hydrogen through the heat exchange mechanism I and cooler; the raw material gas is purified hydrogen with a pressure of 4.0 MPa, a purity of more than 99.99%, and trace impurity indicators that do not meet the requirements of hydrogen for fuel cells. The specific content of trace impurities in the product gas needs to meet the national standard for pure hydrogen.

[0054] The low-temperature raw material hydrogen temperature is ≤ -155°C, and the cooler is a liquid nitrogen evaporative cooler. In front of the refrigeration mechanism, there is a cooler that operates at the initial stage of operation to cool down the hydrogen entering the refrigeration mechanism to -155°C to ensure the operation of the hydrogen refrigeration mechanism at the initial stage of operation.

[0055] (2) A part of the low-tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com