Exhaust structure of steaming and baking cooking equipment and steaming and baking all-in-one machine

A technology of cooking equipment and exhaust port, which is applied to steam cooking utensils, roasters/barbecue grills, cooking utensils, etc., which can solve problems such as inconvenient control operations, complex structures, and the impact of inner tank sealing, so as to improve cooking effect, simple structure, effect of promoting condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The present invention will be further described in detail below with reference to the embodiments of the drawings.

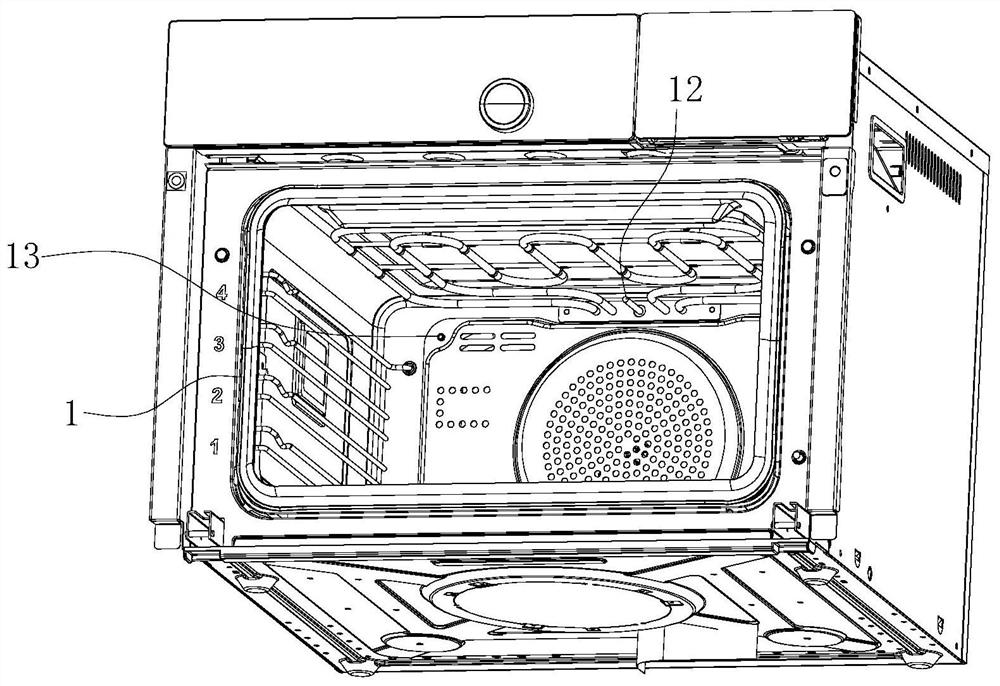

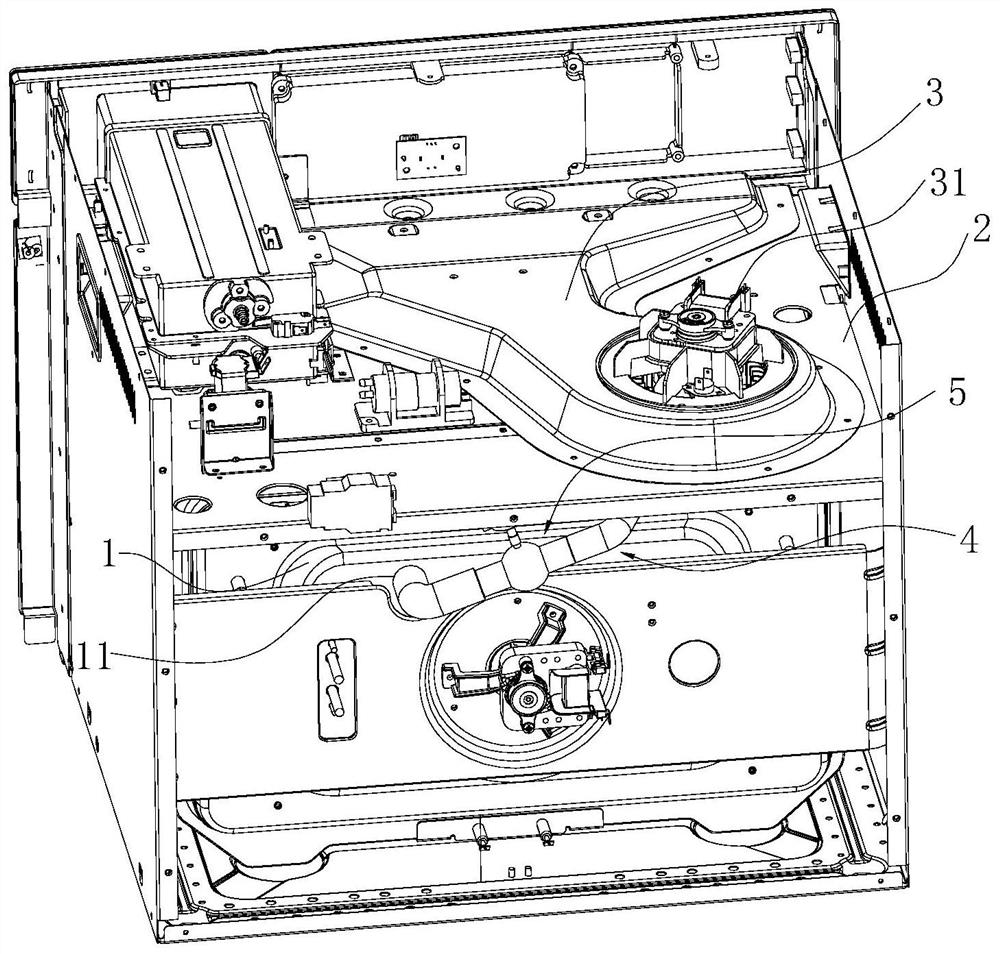

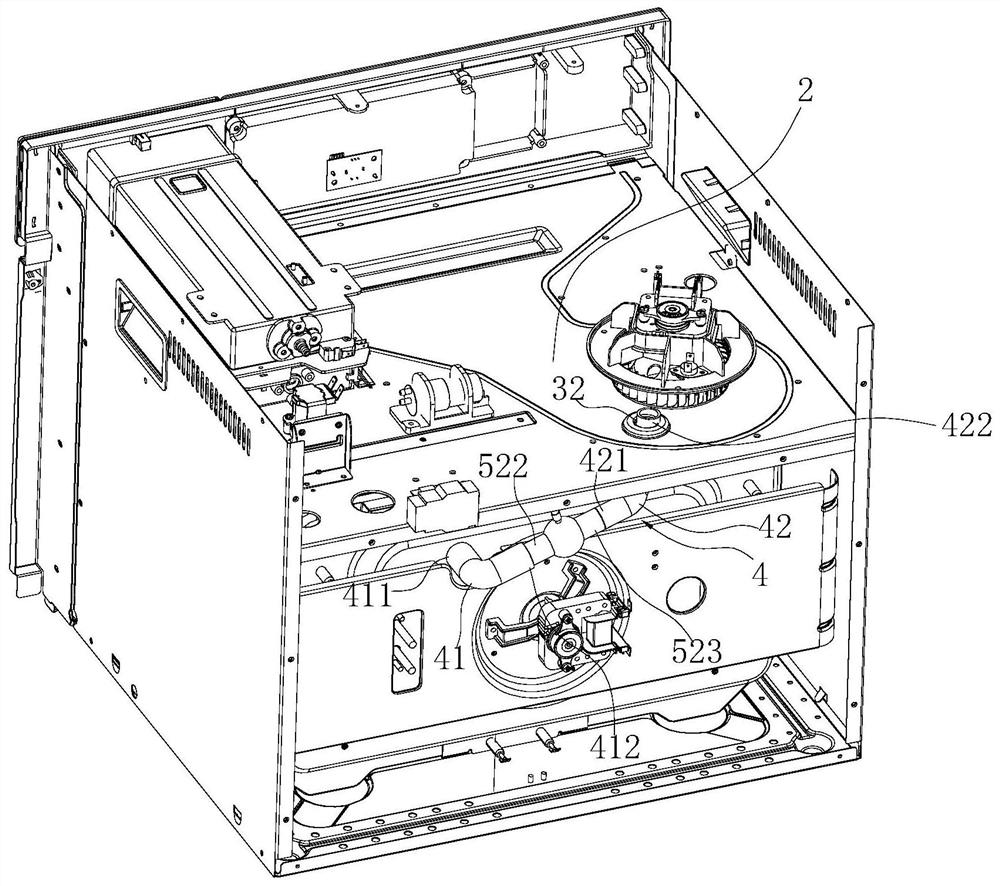

[0035]Such asFigure 1-15As shown, a steaming and grilling cooking device, in this embodiment, is specifically a steaming and grilling integrated machine, which includes an exhaust structure including an inner container 1 and an exhaust fan 31 arranged above the inner container 1 Exhaust channel 3. The upper part of the back plate of the inner tank 1 is provided with an exhaust port 11, and the exhaust port 11 communicates with the intake port 601 of the exhaust passage 3 through the exhaust pipe 4.

[0036]Furthermore, the exhaust pipe 4 includes a first pipe body 41 and a second pipe body 42, wherein the first end 411 of the first pipe body 41 communicates with the exhaust port 11 of the inner liner 1, and the second pipe body 42 The second end 421 communicates with the air inlet 601 of the exhaust passage 3 described above. In addition, it also includes an exhaust v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com