One-step anodic oxidation preparation process of inorganic flexible super-hydrophobic super-oleophylic copper net

A technology of anodic oxidation and preparation process, which is applied in the direction of chemical instruments and methods, membrane, semi-permeable membrane separation, etc. It can solve the problems of complex preparation method of CuS and inability to achieve extreme modification state in one step, so as to achieve good industrial application prospects and high efficiency of oil and water Separation performance, the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

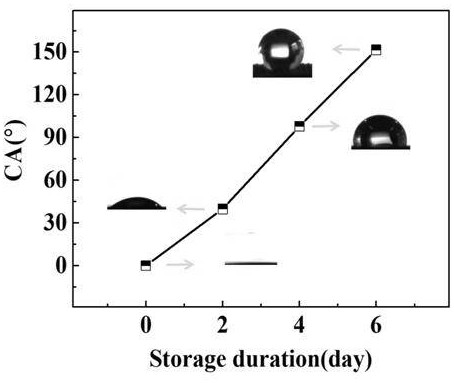

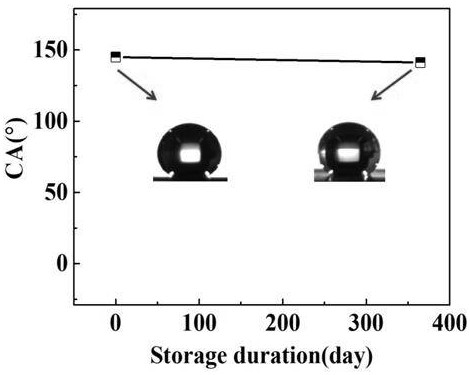

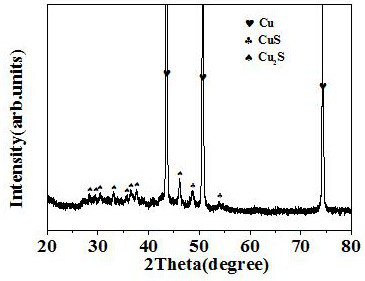

Embodiment 1

[0029] At room temperature, 60.045g of sodium sulfide nonahydrate (Na 2 S·9H 2 O) Add to 500mL water (H 2 O) in a weighing bottle, and fully stirred, after the sodium sulfide is completely dissolved, put the prepared solution in an environment of less than 4°C and refrigerate it, and use it as the electrolyte in the anodizing process. The cut copper grids were ultrasonically cleaned with acetone ethanol deionized water for 20 min, and further cleaned in HNO 3 and H 2 The copper mesh was ultrasonically polished in a mixture of O (volume ratio 3:1). The polished copper mesh is anodized, the copper mesh is used as the anode, the graphite sheet is used as the cathode, and the electrolyte is Na 2 S (0.5mol / L) solution, the anodizing time is 2min, and the current is 5mA. The anodized sample was washed repeatedly with deionized water and dried, and then the sample was annealed in air at a temperature of 200 °C for two hours. The sample was placed in the air at room temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap