Wet dust removal cutting platform

A cutting platform, wet dust removal technology, applied in the direction of welding/cutting auxiliary equipment, auxiliary equipment, plasma welding equipment, etc., can solve a large amount of dust, debris, not suitable for vacuum cleaner dust removal, debris density and other problems, to achieve no noise Pollution and dust removal effects are stable and adaptable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

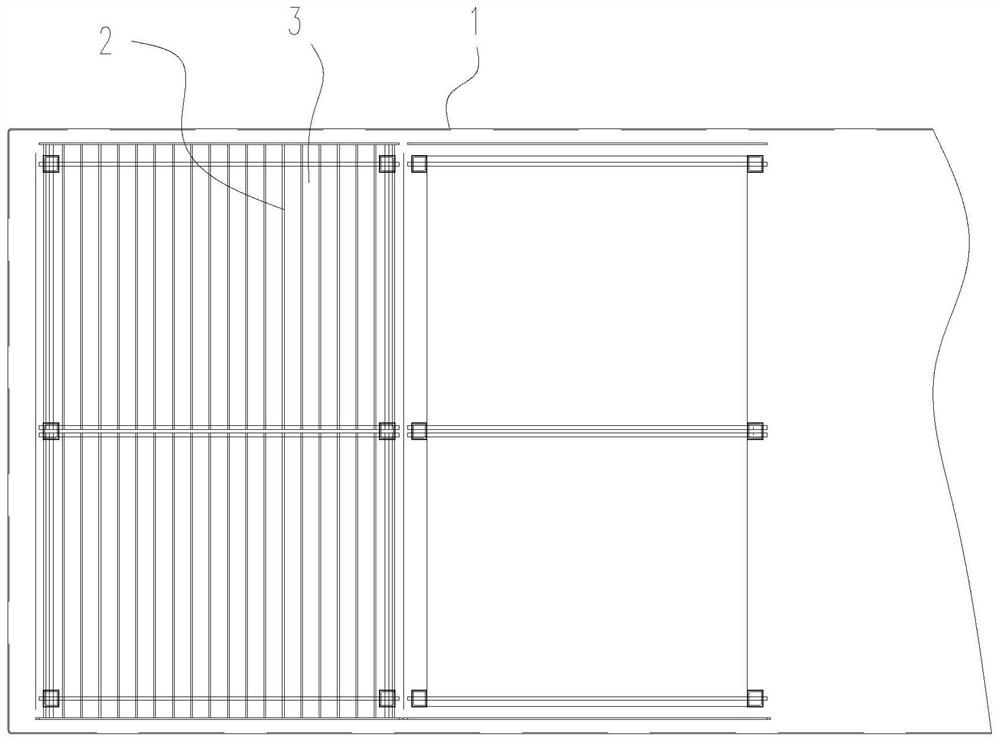

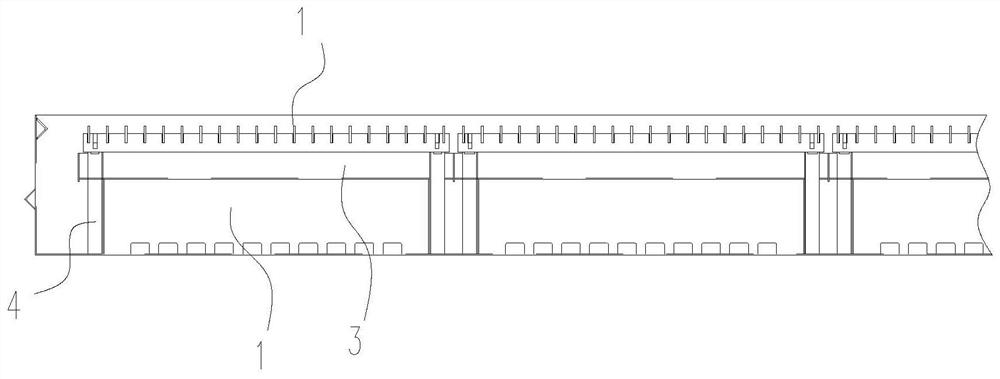

[0023] Such as figure 1 , 2 As shown, a wet dust removal cutting platform includes a water tank 1 and a cutting table located in the water tank. The cutting table is a grid surface, that is, a plane arranged at intervals by strip plates 2. Below the cutting table, there are The slag collecting pan 3, debris can fall into the slag collecting pan below from the gap between the strip plates. An air bag 4 is arranged in the water tank to control the water surface of the water tank to move up and down on the cutting table by controlling the size of the air bag, so as to clear the slag on the cutting table.

[0024] Multiple small wet dust removal cutting platforms are arranged to form a large wet dust removal cutting platform. The specific number of small wet dust removal cutting platforms can be determined according to needs. The lifting device of each small wet dust removal cutting platform is independently controlled, which is convenient for the position of dust removal as requ...

Embodiment 2

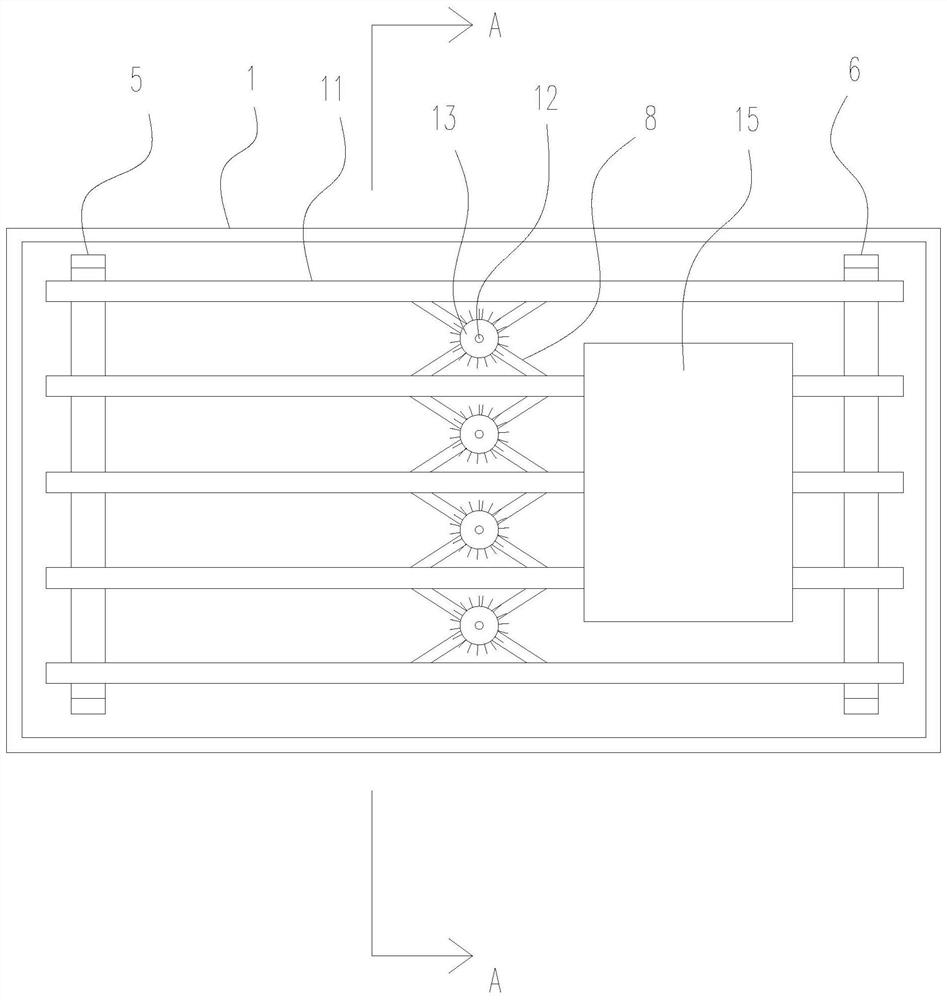

[0026] Such as image 3 , 4 As shown in . state. Lifting support can be controlled by cylinder 7.

[0027] The structure of the scissor deformation frame is arranged between the support rods is similar to the lifting mechanism of the scissor lift truck, that is, the scissor deformation frame is composed of a plurality of scissor units, and the scissor unit includes two rod bodies 8, two The middle of each rod body is connected by a middle hinge 9, and the rod body ends of two adjacent scissor units are connected by an end hinge 10.

[0028] The support rod is provided with a guide groove 111, and the end hinge of the scissors deformation frame is slidably fitted in the guide groove, and the height adjustment of the first lifting bracket and the second lowering bracket makes the support rod tilt As a result, the scissor deformation frame slides to one side, and the distance between the support rods can also be changed synchronously, so as to meet the requirements of workpie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com