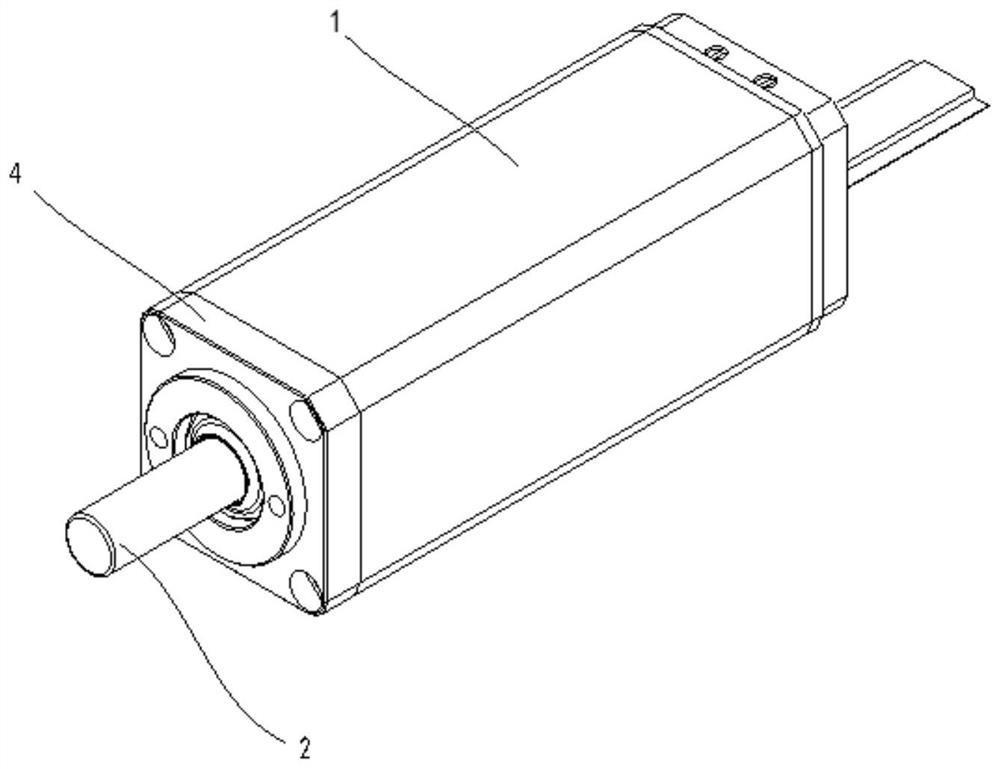

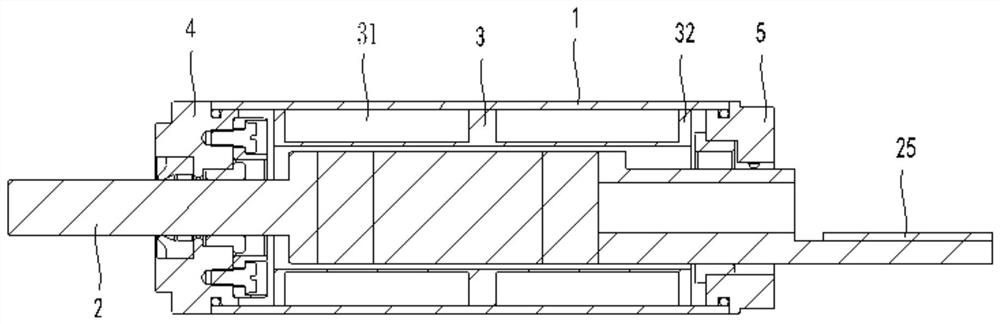

Linear bearing and tubular linear motor

A technology of linear bearings and linear motors, applied in the field of electric motors, can solve the problems that a single bearing does not have the function of positioning in the circumferential direction, and linear bearings cannot be used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

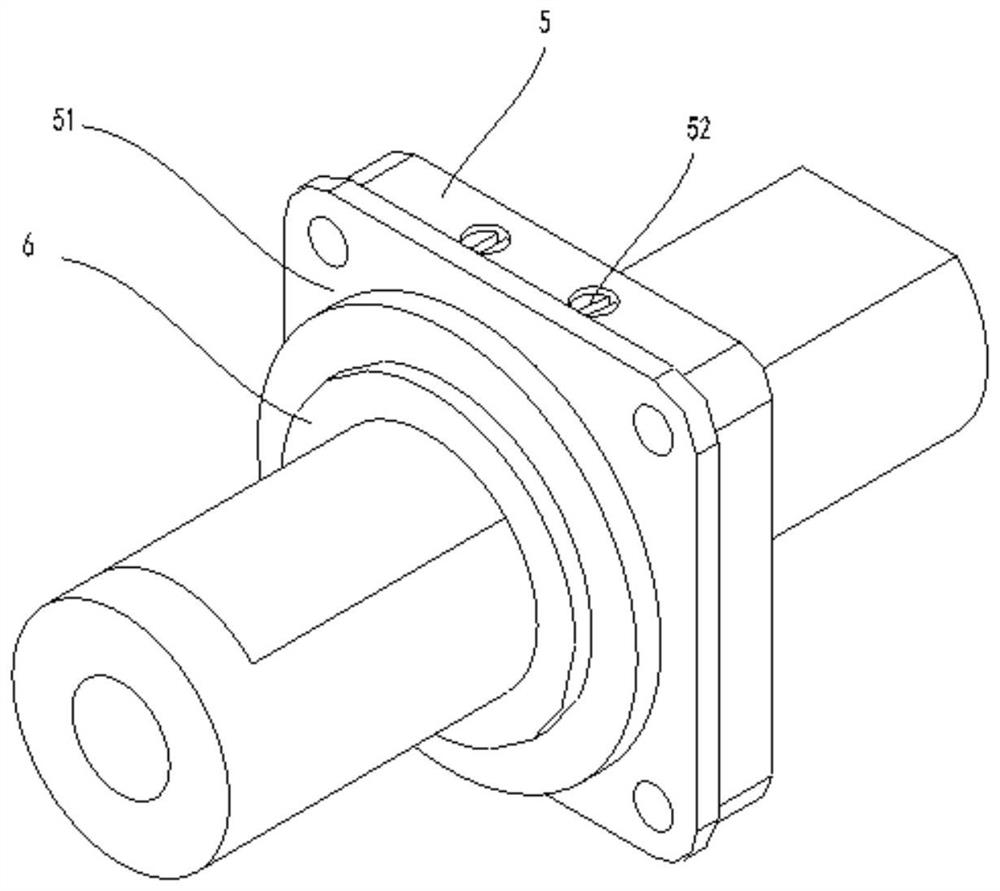

[0051] A linear bearing such as Figure 3 to Figure 7 as shown,

[0052] Including mandrel, sliding sleeve 6, bearing seat 51 and adjusting part 52;

[0053] The sliding sleeve 6 is set in the bearing seat 51, the mandrel is slidably connected in the sliding sleeve 6, the adjusting member 52 is arranged on the bearing seat 51, and the adjusting member 52 faces the One end of the mandrel abuts against the mandrel and is used to adjust the angle of the mandrel along the circumferential direction.

[0054] In the linear bearing 5 provided by the embodiment of the present invention, the mandrel can move linearly in the axial direction in the sliding sleeve 6, and the adjusting member 52 abuts on the mandrel, and the adjusting member 52 positions the circumferential direction of the mandrel to prevent the mandrel from moving along the circumference of the mandrel. The direction rotates, and the angle of the mandrel along the circumferential direction can also be adjusted through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com