Intelligent auxiliary system and method for regular inspection of pressure pipeline

A pressure pipeline and auxiliary system technology, which is applied in other database retrieval, special data processing applications, instruments, etc., can solve the problems that the inspection quality is greatly affected by human factors and the inspection efficiency is low, so as to improve the inspection efficiency and inspection quality, The effect of reducing the influence of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

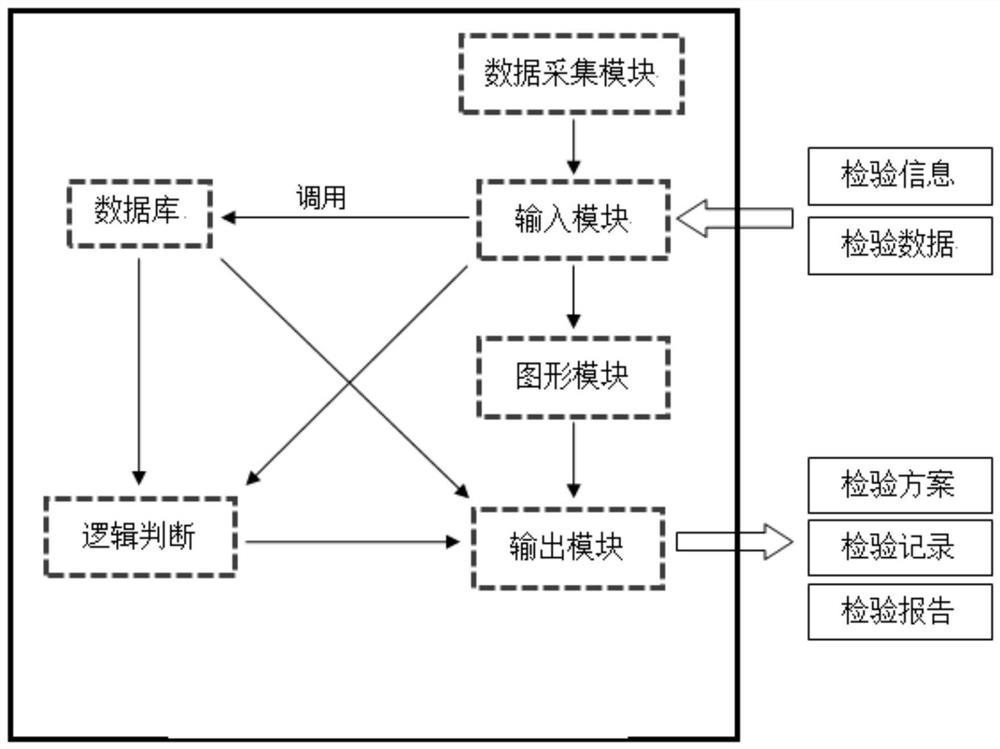

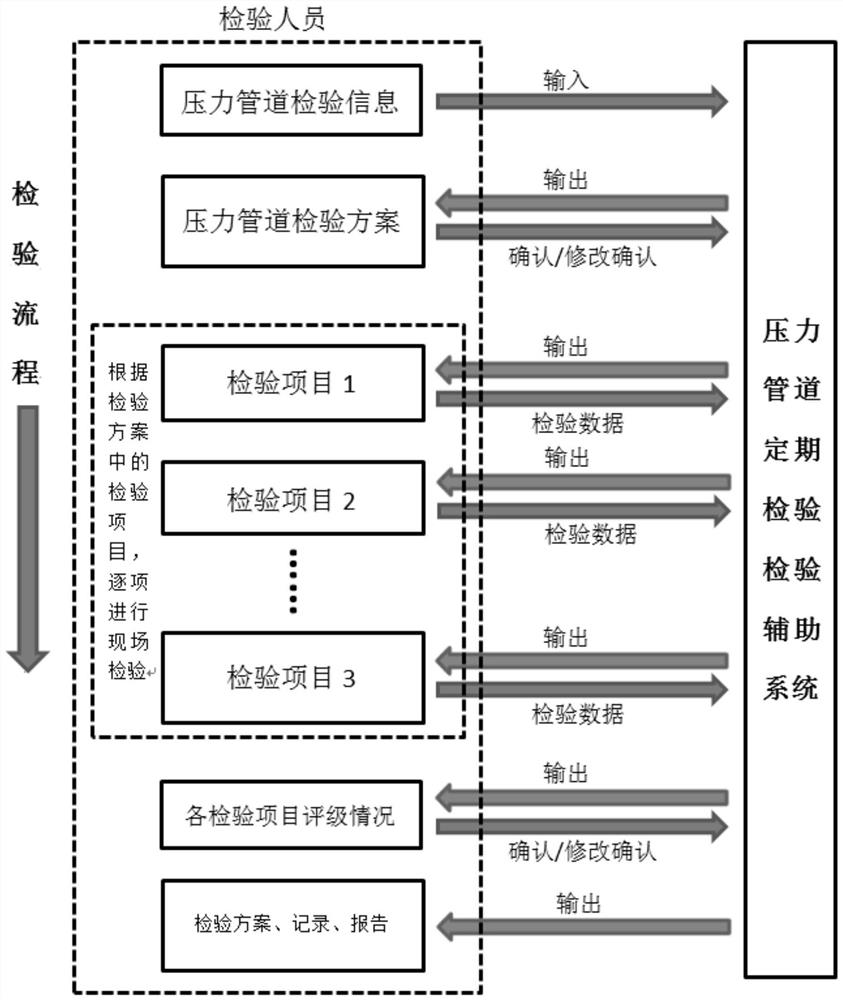

[0033] The invention provides an intelligent auxiliary system for regular inspection of pressure pipelines, such as figure 1 shown, including:

[0034] Database for storing relevant codes and standards for periodic inspection of pressure pipelines;

[0035] The data acquisition module is connected to the measuring instrument by Bluetooth connection, and collects the inspection data of the pressure pipeline to be inspected, such as connecting the thickness measuring instrument, collecting and measuring the wall thickness value of the pressure pipeline, connecting the hardness tester, collecting and testing the hardness value of the pressure pipeline, etc.;

[0036] The input module receives the data sent by the data acquisition module and external inspection data and inspection information, realizes the input of pressure pipeline equipment information and inspection data, and calls the corresponding specifications and standards in the database, and sends part of the received da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com