Quality analysis method and system based on machine vision in new energy battery manufacturing

A technology of machine vision and quality analysis, applied in image analysis, instruments, image data processing, etc., can solve the problems of only a small amount of sampling inspection, low efficiency, and affecting production line capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

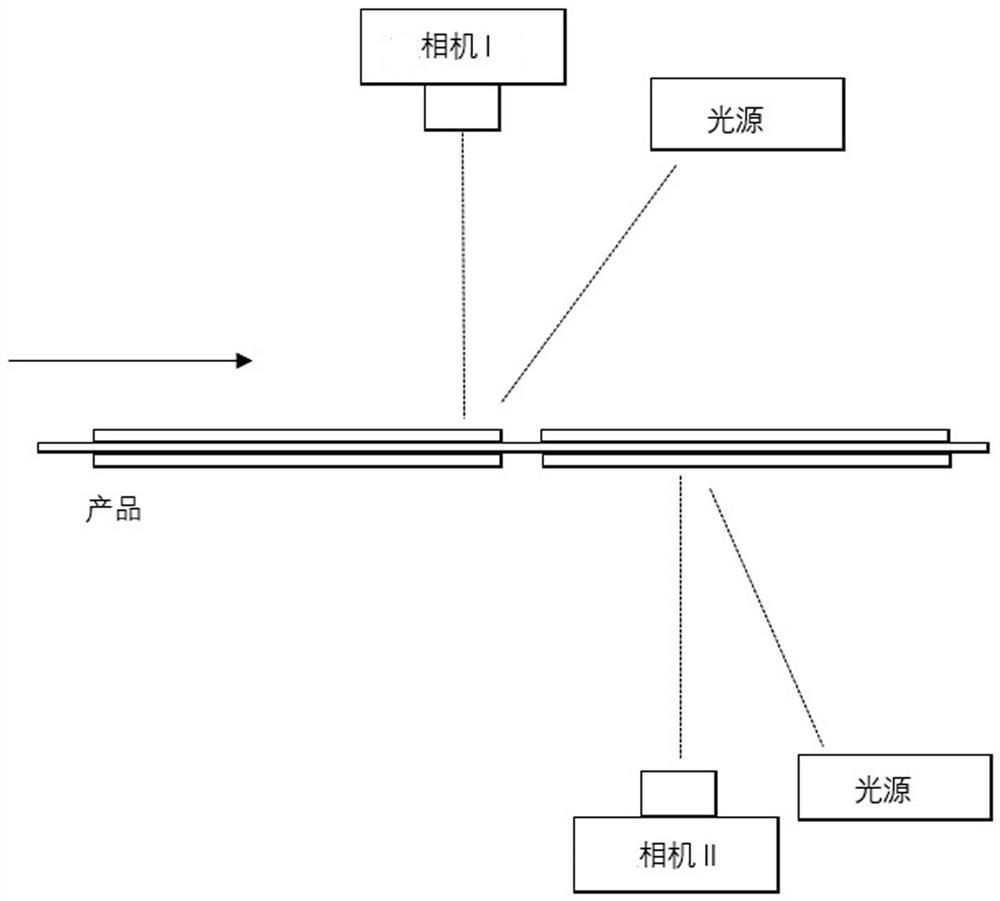

[0025] This embodiment is a quality analysis system based on machine vision in the manufacture of new energy batteries. It has a host computer and a camera I, camera II, an encoder and an alarm device connected to the host computer. The front image of the product is collected after the trigger signal; the camera II is used to collect the reverse image of the product after receiving the image collection trigger signal; the encoder is in contact with the product, used to obtain the transmission distance of the product, and is used for camera I after the product is transmitted for a certain distance. , II provide image acquisition trigger signal; the upper computer has a processor and a memory, and a computer program is stored in the memory. When the computer program is executed by the processor, the steps of the quality analysis method based on machine vision in the manufacture of new energy batteries are realized.

[0026] In this embodiment, the quality analysis method based on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com