An efficient and continuous silicone glue coloring system

A coloring system and silicone glue technology, applied in chemical instruments and methods, chemical/physical processes, mixers, etc., can solve the problems of limited mixing capacity of static mixers, affecting the quality of silicone glue products, etc., to improve the initial mixing effect, reduce chromatic aberration, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

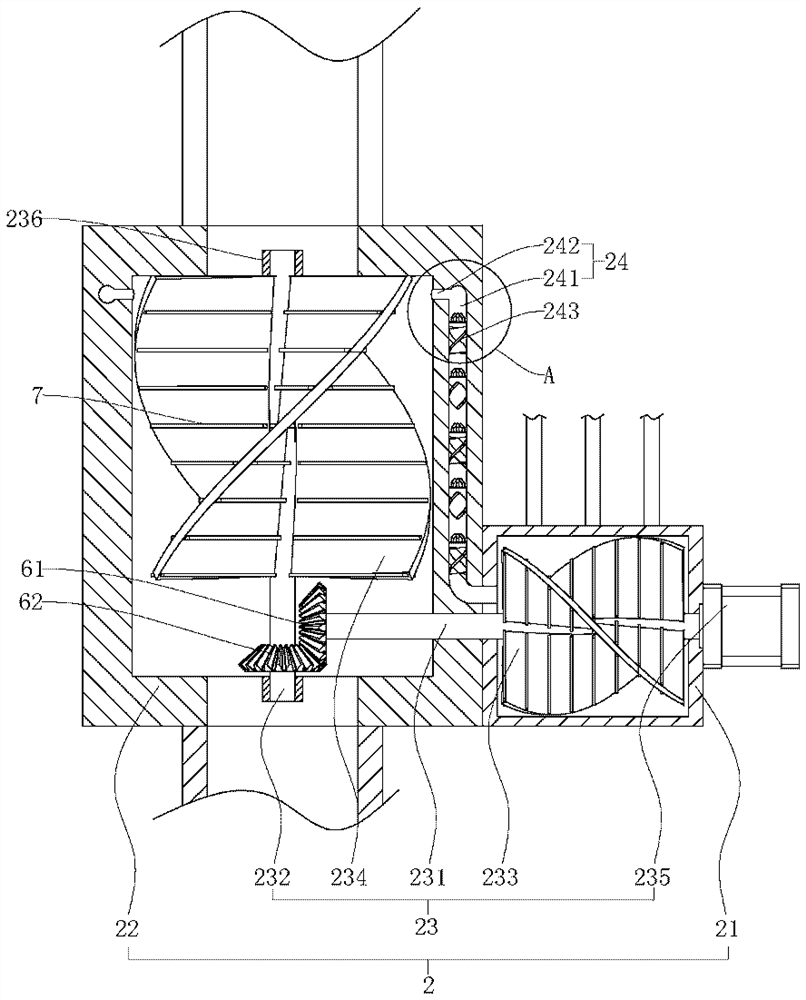

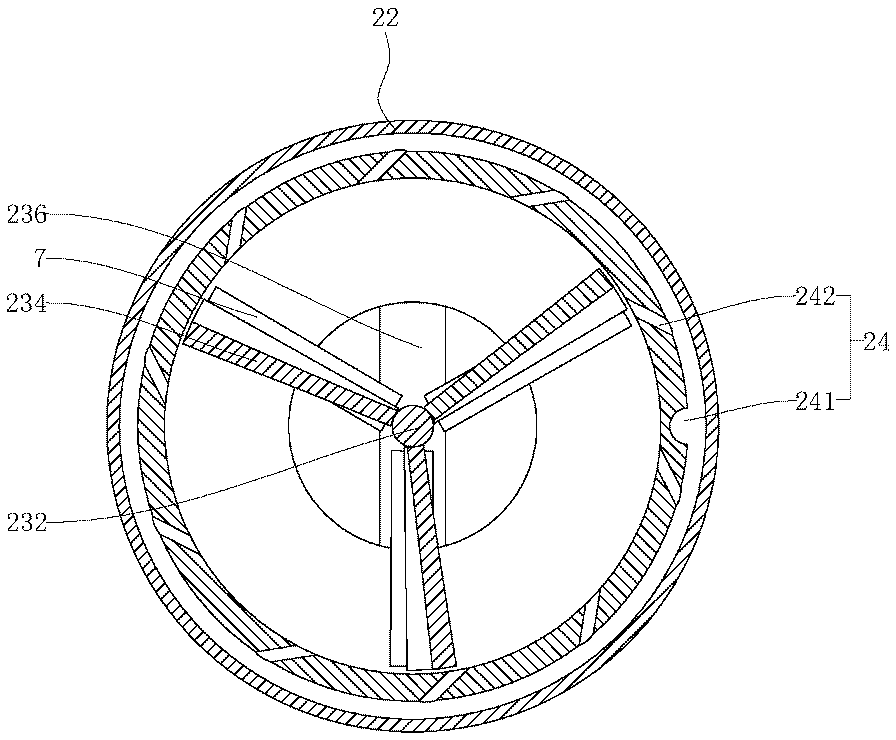

[0036] The following is attached Figure 1-5 The application is described in further detail.

[0037] The embodiment of the present application discloses a high-efficiency continuous silicone glue coloring system.

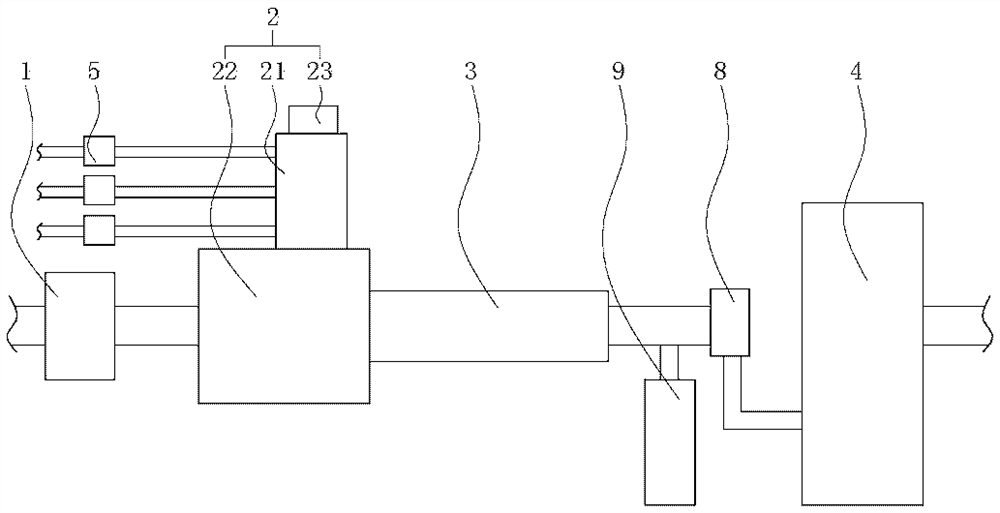

[0038] refer tofigure 1 , the high-efficiency continuous silicone glue coloring system sequentially includes a primary color glue metering cylinder 1, a dynamic mixer 2, a static mixer 3 and a dispensing machine 4 along the conveying direction of the primary color glue. Slurry metering cylinder 5; Wherein, the discharge port of each color paste metering cylinder 5 and the discharge port of primary color glue metering cylinder 1 are all connected with the feed inlet of dynamic mixer 2, and the discharge port of dynamic mixer 2 is connected with The feed port of the static mixer 3 is connected, and the discharge port of the static mixer 3 is connected with the packing machine 4 . The primary color glue metering cylinder 1 can be used to measure and extract the prim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com